Rigid foamed plastic

A technology of rigid foam plastic and foam stabilizer, applied in the field of foam plastic, can solve the problems of unsatisfactory performance of rigid foam plastic, poor gripping ability, etc., achieve good dimensional stability, eliminate expansion, contraction and deformation problems, reduce The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

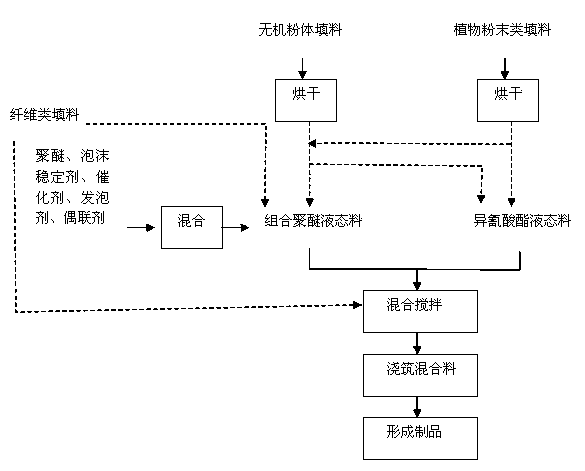

Method used

Image

Examples

Embodiment 1

[0063] Sucrose polyether polyol (commercially available) 50 parts, sorbitol polyether polyol (commercially available) 30 parts, propylene glycol polyether polyol (commercially available) 7 parts, silane surfactant (commercially available) 2.5 parts, N , 1 part of N-dimethylcyclohexane (commercially available), 1.5 parts of triethylenediamine (A33), 3 parts of glycerin (commercially available), and 5 parts of fluorodichloroethane (141B) to form a combined polyether A 100 parts of components, 75 parts of calcium carbonate (1250 mesh) (commercially available), 10 parts of wood powder (200 mesh) (commercially available) and 15 parts of alkali-free chopped glass fiber (commercially available) with a length of less than 5 mm and a diameter of 10 μm Parts are fully stirred and mixed to form a combined polyether component containing various filler components, and then mixed with 110 parts of polymethylene polyphenylisocyanate liquid material PM200 (commercially available) and injected ...

Embodiment 2

[0065] Sucrose polyether polyol (commercially available) 50 parts, sorbitol polyether polyol (commercially available) 30 parts, propylene glycol polyether polyol (commercially available) 7 parts, silane surfactant (commercially available) 2.5 parts, N, Composition A 100 parts of components, 75 parts of calcium carbonate (1250 mesh) (commercially available) and 15 parts of alkali-free chopped glass fibers (commercially available) with a length of less than 5 mm and a diameter of 10 μm (commercially available) are fully stirred and mixed to form a filler-containing component Combining polyether components, 110 parts of polymethylene polyphenyl isocyanate liquid material PM200 (commercially available) and 10 parts of wood flour (200 mesh) (commercially available) are fully dispersed by electromagnetic shock to form isocyanate liquid material containing filler components, Fully mix the combined polyether containing filler component and the isocyanate liquid material containing fil...

Embodiment 3

[0067] Sucrose polyether polyol (commercially available) 50 parts, sorbitol polyether polyol (commercially available) 30 parts, propylene glycol polyether polyol (commercially available) 7 parts, silane surfactant (commercially available) 2.5 parts, N, Combination of 1 part of N-dimethylcyclohexane (commercially available), 1.5 parts of triethylenediamine A33 (commercially available), 3 parts of glycerin (commercially available), and 5 parts of monofluorodichloroethane 141B (commercially available) 100 parts of polyether A component, fully stirred and mixed with 75 parts of calcium carbonate (1250 mesh) (commercially available) to form a combined polyether component containing filler components, polymethylene polyphenyl isocyanate liquid material PM200 (commercially available ) 110 parts and 10 parts of wood flour (200 mesh) (commercially available) are fully dispersed by electromagnetic shock to form a liquid isocyanate material containing a filler component, and the combined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com