Construction method for overcoming deformation of anti-floating fixed diameter anchor head or expanded head anchor rod system

A technology of expanding head and anchor rod, which is applied in the direction of foundation structure engineering, sheet pile wall, protective device, etc., can solve the problems such as the adverse effect of basement waterproofing, the long requirement of foundation pit dewatering, and the damage of the main structure, so as to achieve simple construction and reduce displacement , Eliminate the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

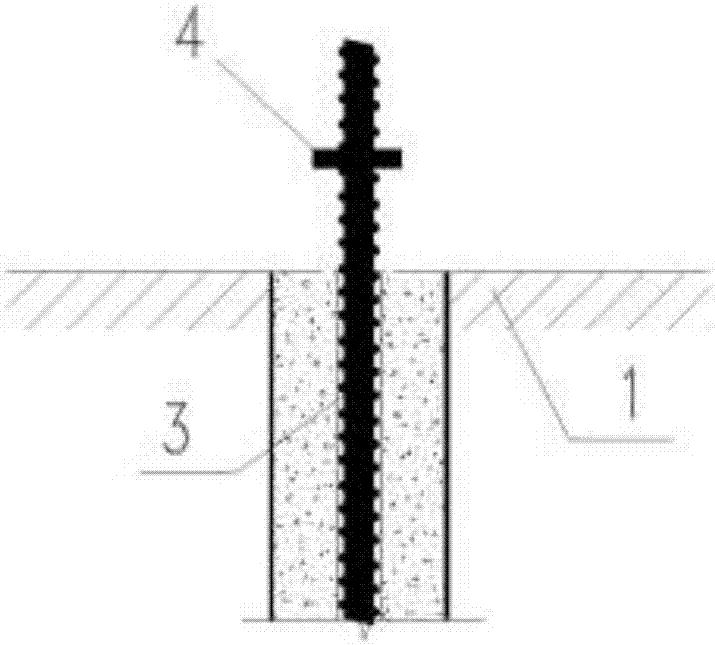

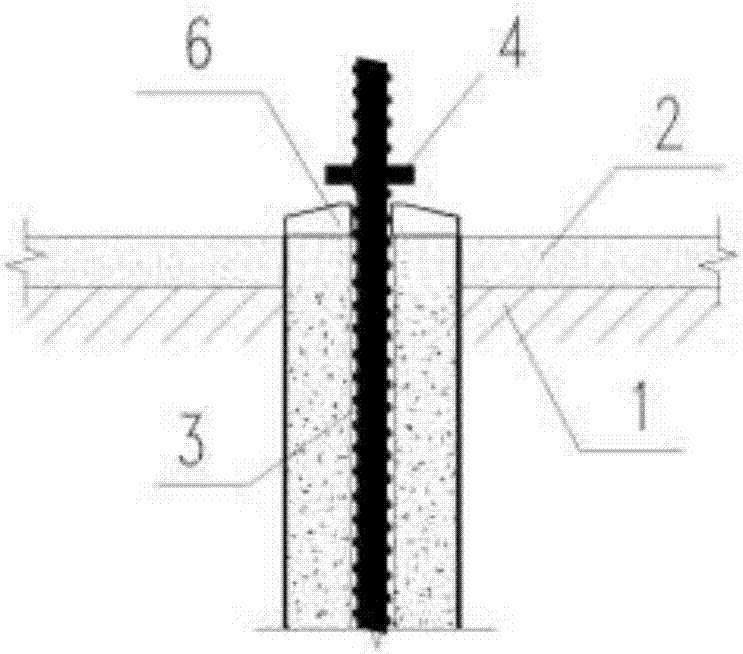

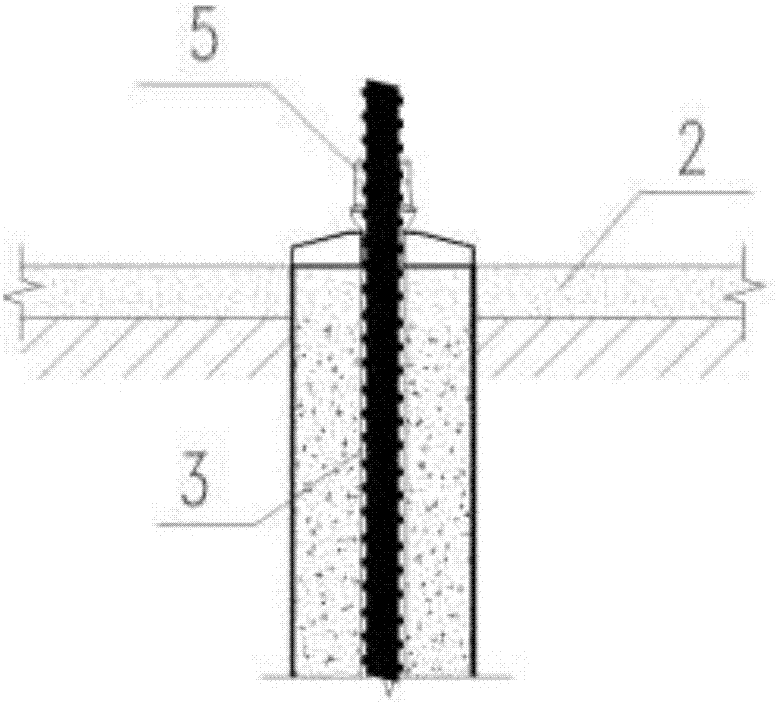

[0040] Base 1, concrete cushion 2, prestressed tendon (threaded steel bar) 3, waterproof strip 4, prestressed nut 5, anchor backing plate 6 (steel plate thickness about 16mm, diameter 200-300mm), thread on the anchor backing plate Reinforcement hole 6-2, anchor plate 6-1, concrete miniature pile 7, concrete floor 8, concrete floor reinforcement 9, deformation box 11 (thickness 30-200mm, diameter is slightly smaller than free diameter hole), reinforcement cage 10 can It is a fixed (fixed diameter) or enlarged head structure, and the steel cage prestressed tendon (threaded steel bar) 3 is fixed.

[0041](1) Prestress application

[0042] Under the premise of certain soil layer conditions, by applying prestress to eliminate the deformation of the anchor rod, the displacement of the engineering anchor rod can be well reduced. Considering comprehensively, in this paper, the diameter of the ordinary section of the anchor rod (concrete poured around the threaded steel bar) is increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com