Cooling channel for airfoil with tapered pocket

a cooling channel and airfoil technology, applied in waterborne vessels, climate sustainability, machines/engines, etc., can solve the problems of shortening the life exceeding the material capacity of blades and vanes, and affecting so as to improve the cooling effect of airfoils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

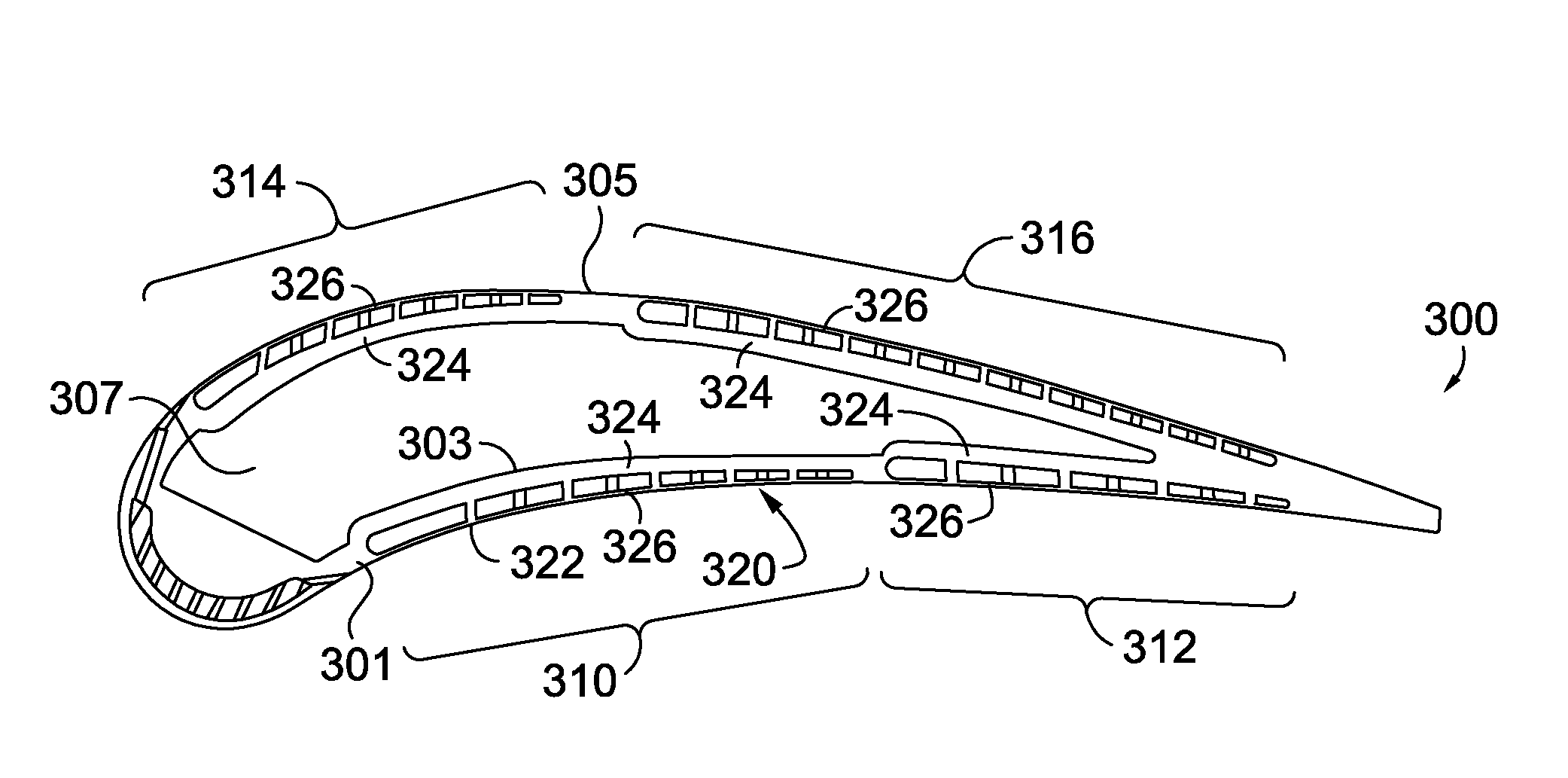

[0031]At a high level, the subject matter of this application generally relates to an airfoil for a gas turbine that includes cooling circuits integrated in various configurations. The airfoil may generally include an airfoil wall with an inner surface and an outer surface that at least partially encloses an airfoil chamber. Cooling circuits may be formed in various locations in the airfoil wall, to provide enhanced heat transfer from the airfoil when the gas turbine is in operation and cooling fluid or gas is passing through the cooling circuits. For turbine hardware operating in harsh environments, the use of this airfoil cooling technology is fully contemplated to be adapted to additional components such as outer and inner diameter platforms, blade outer or inner air shields, or alternative high temperature turbine components.

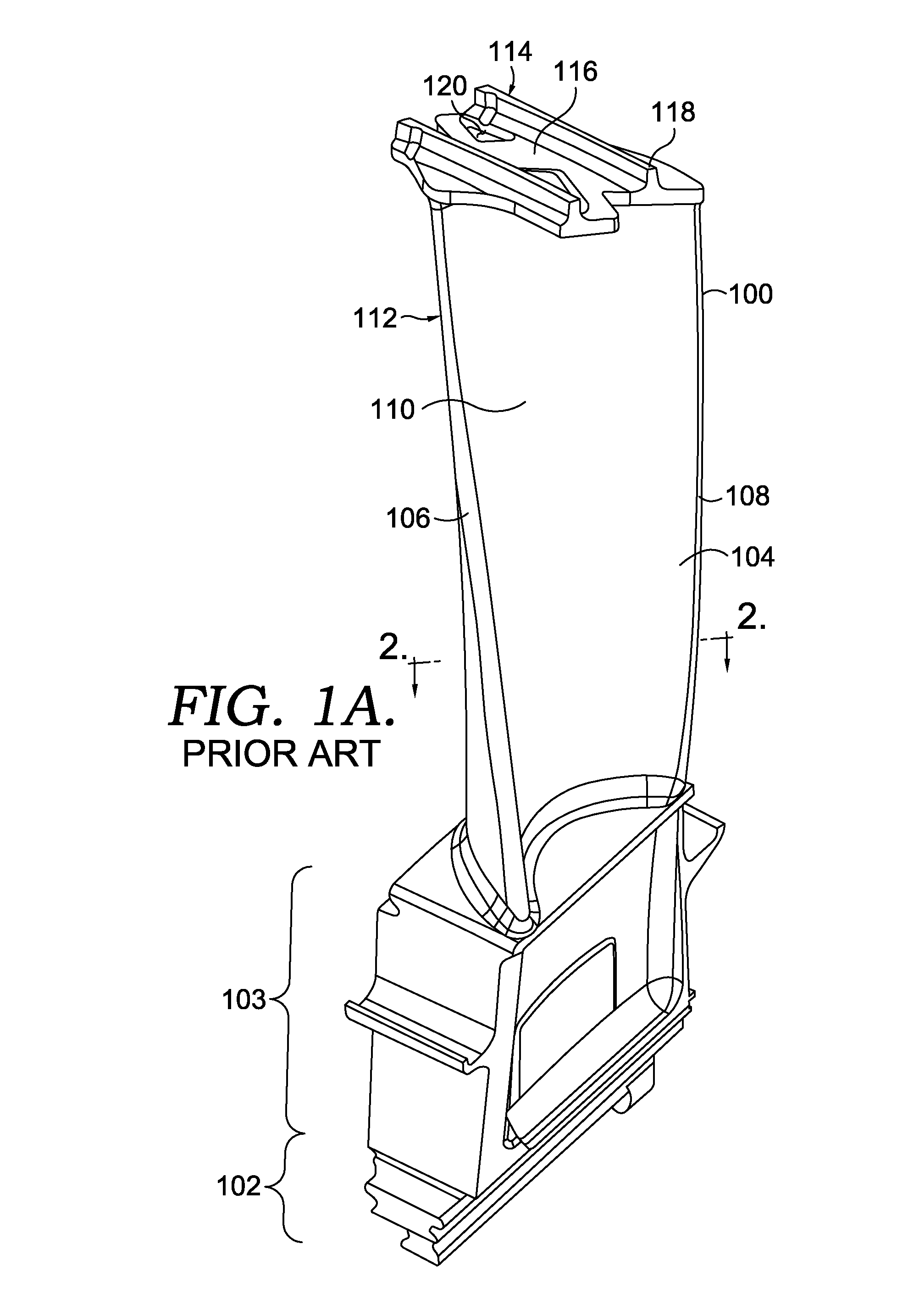

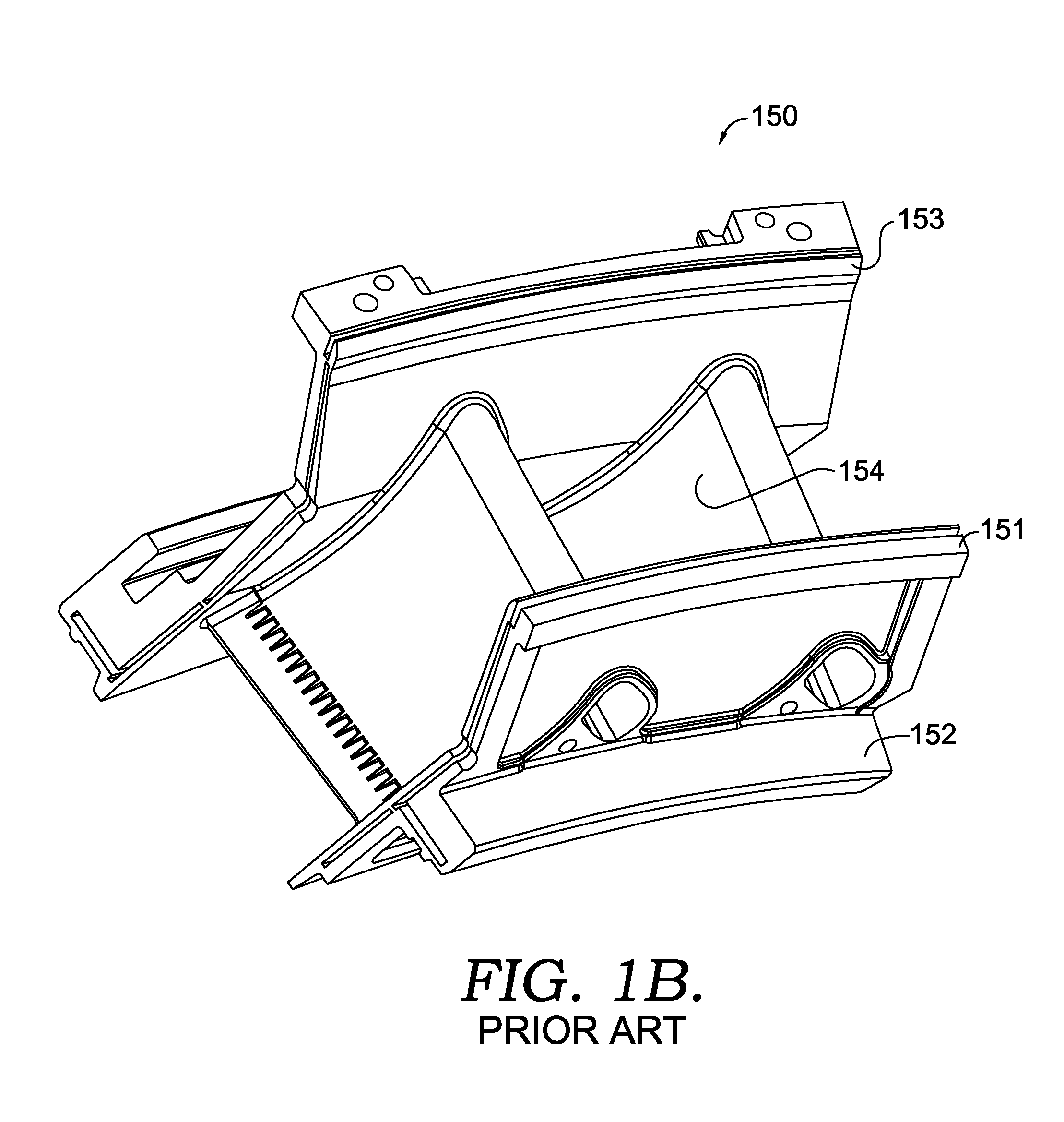

[0032]Referring now to FIG. 1A, a gas turbine blade 100 is provided. The turbine blade 100 comprises a bottom portion commonly referred to as a root 102, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com