Disc type axial-flux motor with oil-immersed circularly cooled stator and segmented armatures

A circulating cooling and axial magnetic technology, applied to synchronous motors with stationary armatures and rotating magnets, cooling/ventilation devices, electric components, etc., can solve the problem of large axial installation dimensions of radial motors and narrow chassis installation space , low power density and low efficiency, etc., to achieve the effect of good weak magnetic speed expansion capability, compact structure, high power density and torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

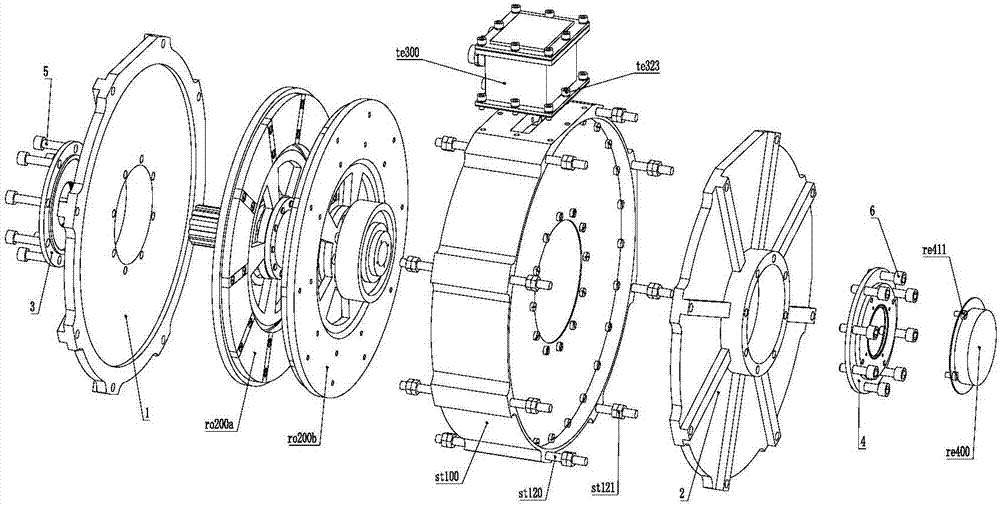

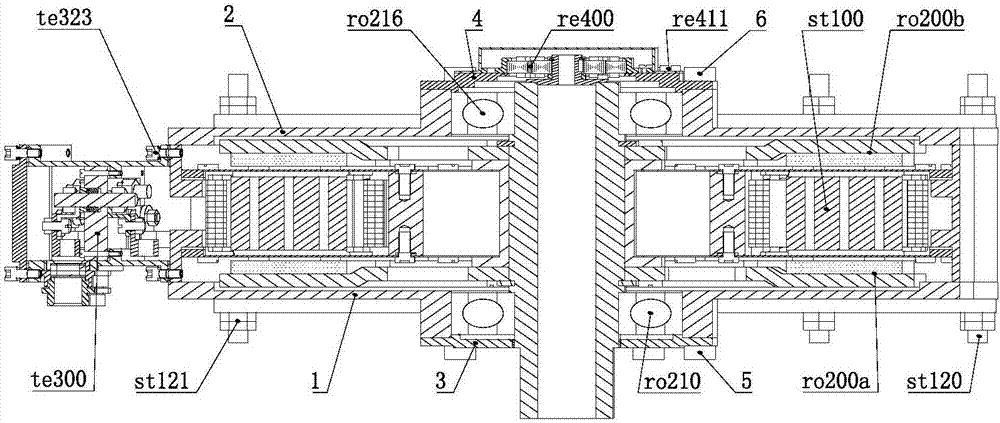

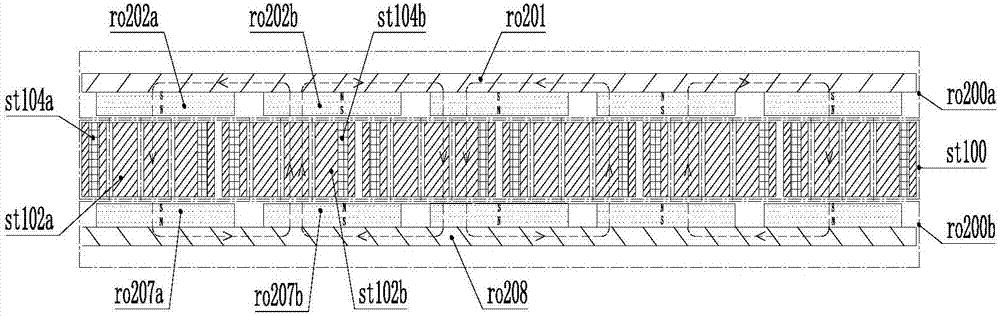

[0030] Such as figure 1 and figure 2 As shown, the present invention is an axial excitation flux permanent magnet synchronous motor, which adopts a double-rotor single-stator structure, and has a main shaft design, wherein the rotor adopts a magnetic steel surface-mounted structure, and the temperature rise management adopts the entire stator oil-immersed circulation cooling and heat dissipation Mode; including stator assembly st100, drive end rotor assembly ro200a, non-drive end rotor assembly ro200b, outlet box assembly te300, resolver assembly re400. The stator assembly st100 is located in the middle of the drive end rotor assembly ro200a and the non-drive end rotor assembly ro200b, the drive end rotor assembly ro200a and the non-drive end rotor assembly ro200b are connected by a spline bushing, and the resolver assembly re400 is fixed to the non-drive end rotor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com