Non-linear fin heat sink

a heat sink and non-linear technology, applied in lighting and heating apparatus, tubular elements, semiconductor devices, etc., can solve the problems of low flow resistance and low heat transfer, high heat loss, and high heat loss, and achieve high power density and dissipation/removing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

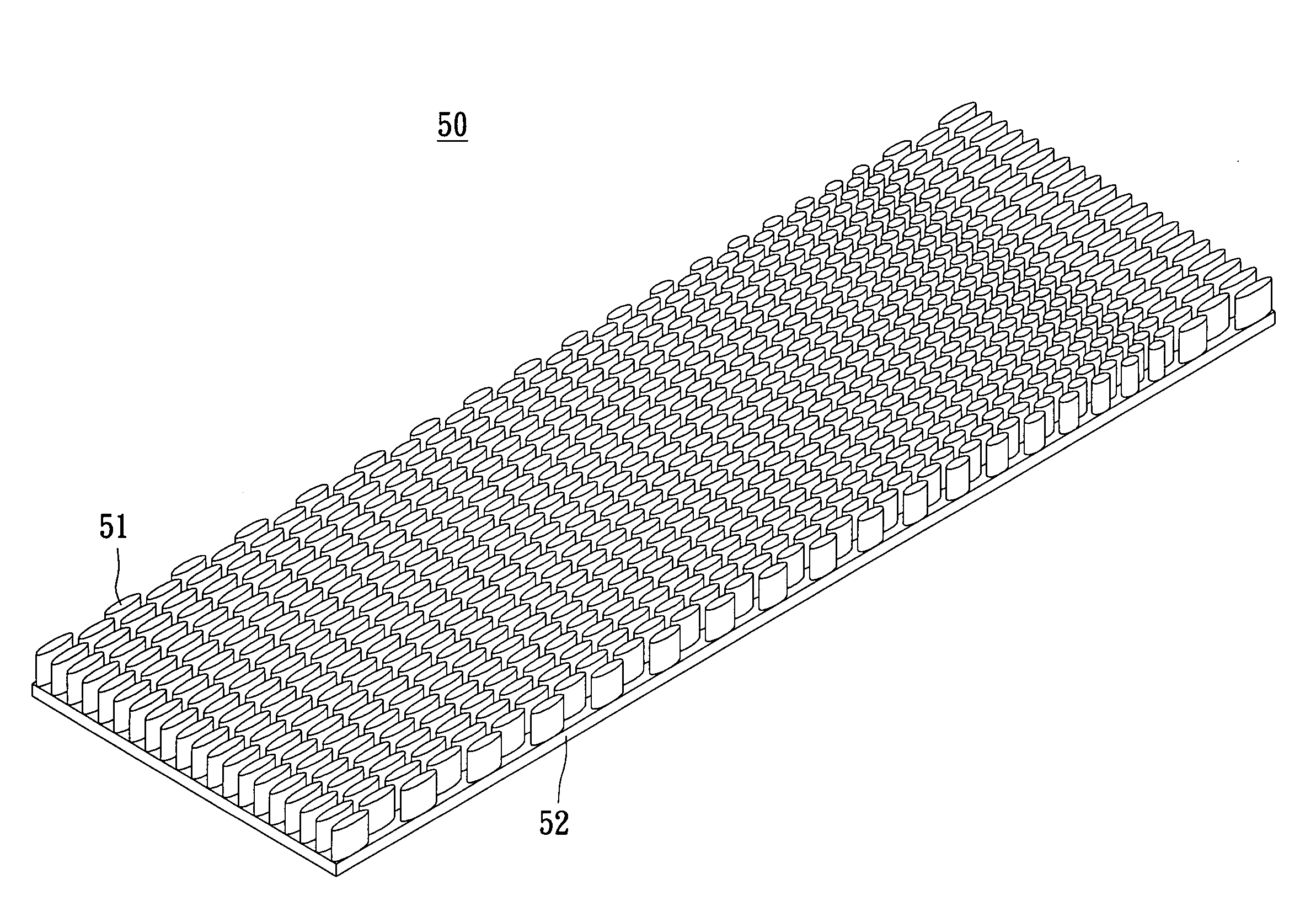

[0106]Referring to FIG. 5, a non-linear fin heat sink 50 is shown. The fins 51 are cross-sectionally shaped as ellipses and attached to a heat sink base 52.

[0107]Referring now to FIG. 6, each elliptical fin 51 has a cross-sectional fin longitudinal dimension 53 and a cross-sectional fin transverse dimension 54. Longitudinal fin spacing (distance between two consecutive fins in the longitudinal direction, i.e., within a given row 55) is represented as 56, and the transverse fin spacing (distance between two consecutive rows 55 or fins 51 in the transverse direction) is represented as 57. Longitudinal rows 55 are in staggered relationship with each other so that fins 51 in alternating longitudinal rows 55 are transversely (columnarly) 58 aligned.

[0108]Referring now to FIG. 7 of the present invention 50, upper lid 59 and base 52 act as boundary layers for flow. Upper lid 59 and base 52 are both planar. Elliptical fins 51 extend an overall fin height 60 from upper surface of the base 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com