Reentry type compound cooling structure

A technology of composite cooling and cooling structure, applied in the combustion method, combustion chamber, combustion equipment and other directions, to achieve the effect of improving convective heat transfer, strengthening convective heat transfer, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

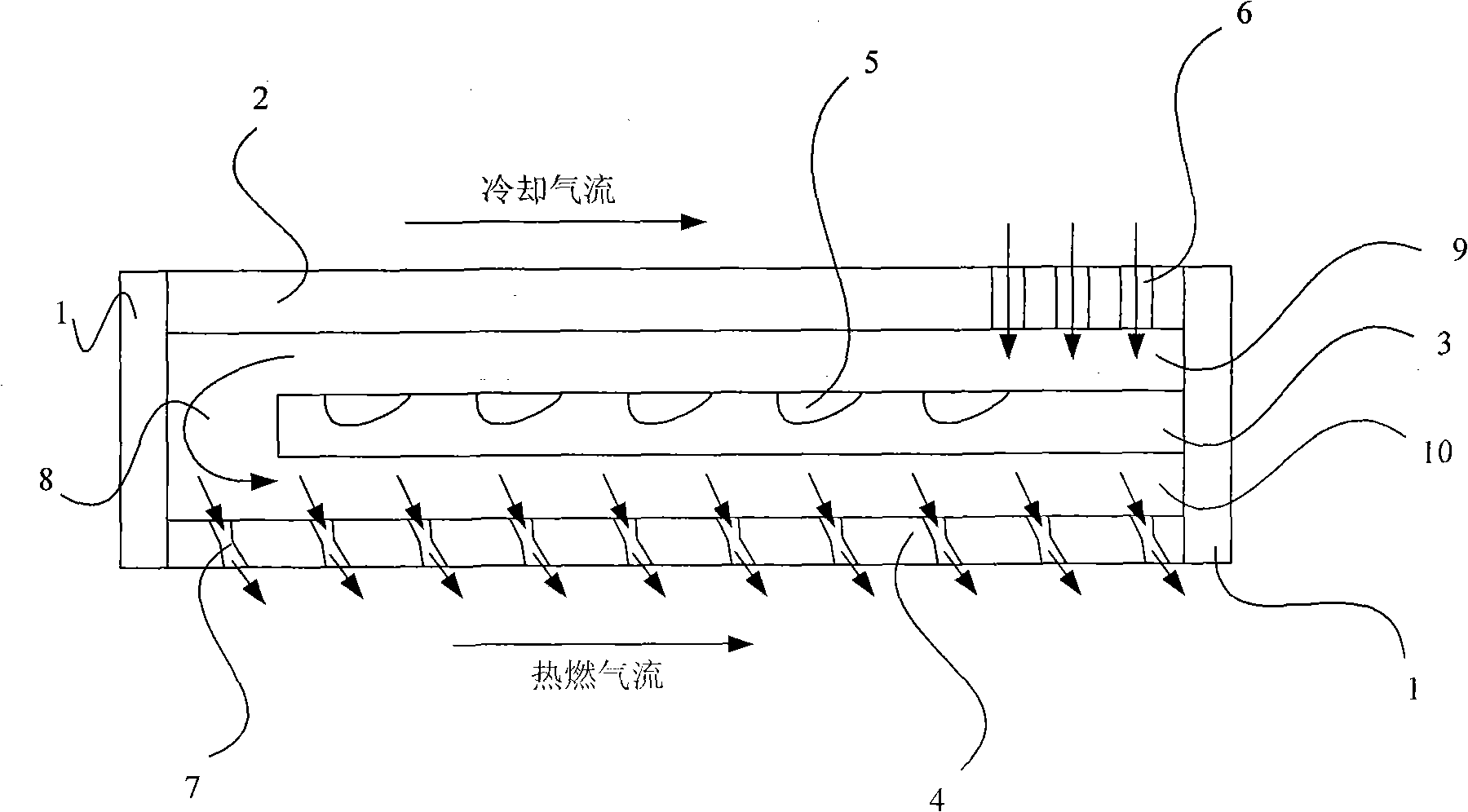

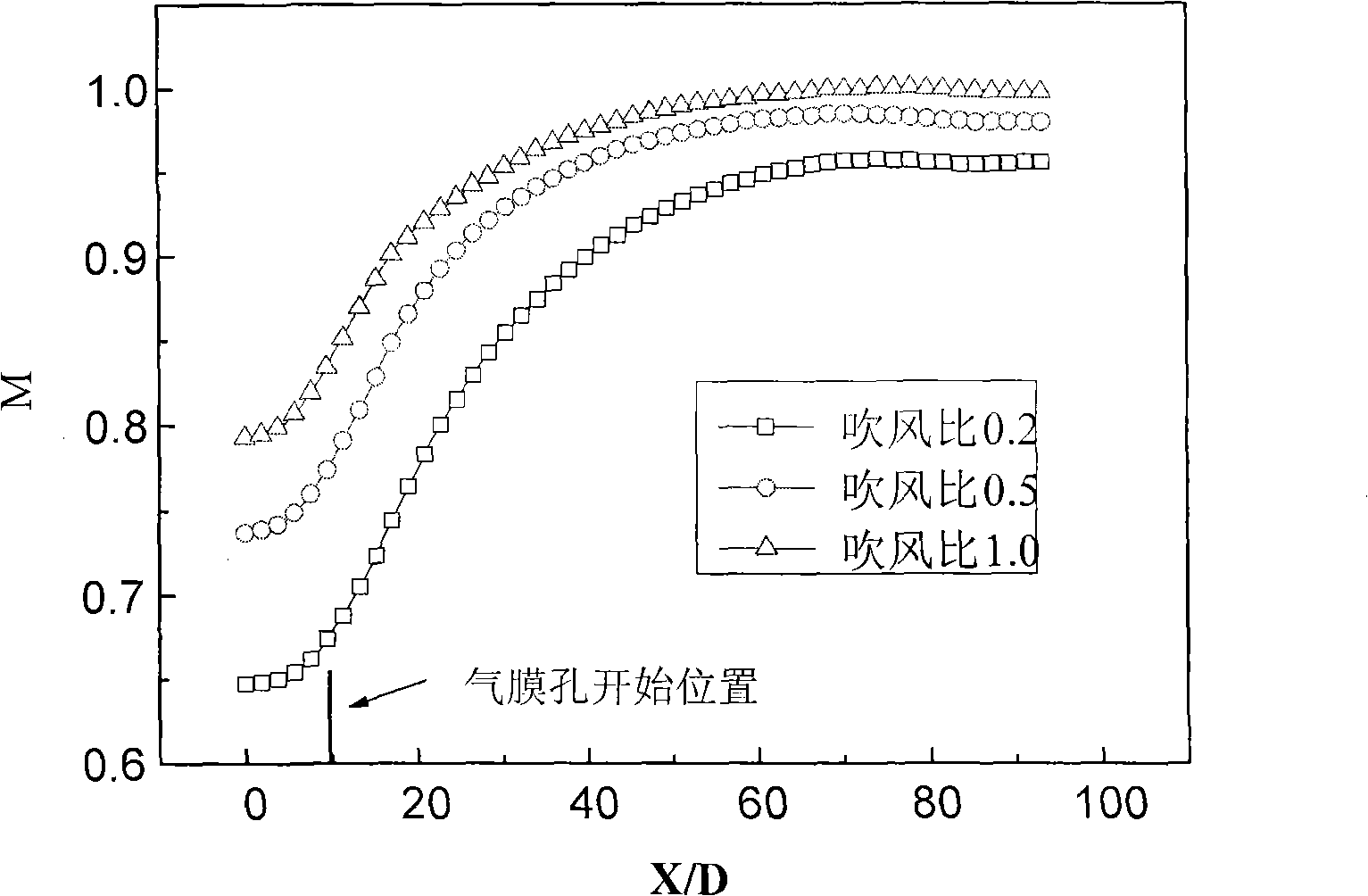

[0028] Adopt a kind of turn-back type compound cooling structure of the present invention to carry out blowing research, research parameter is with reference to the parameter in the typical aero-engine combustor at home and abroad, wherein the inlet temperature and the inlet speed of hot gas stream are respectively T 1 = 1595K and U 1 =80m / s; the inlet temperature of the cooling air flow is T 2 =800K, the import speed is taken as U 2 =8m / s, 20m / s and 40m / s, the blowing ratios of the corresponding cooling airflow at this time are M=0.2, 0.5 and 1.0 respectively.

[0029] The results show that: after the cooling air enters the cooling structure from the impact hole 6 of the rear cavity of the outer wall 2 in the form of impact jet flow, it first impacts and cools the rear section of the middle wall 3, and then flows forward and reverse to perform convective heat exchange. The small cell pit 5 enhances the heat exchange. When the cooling air flows to the front end of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com