Patents

Literature

37results about How to "Temperature fluctuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

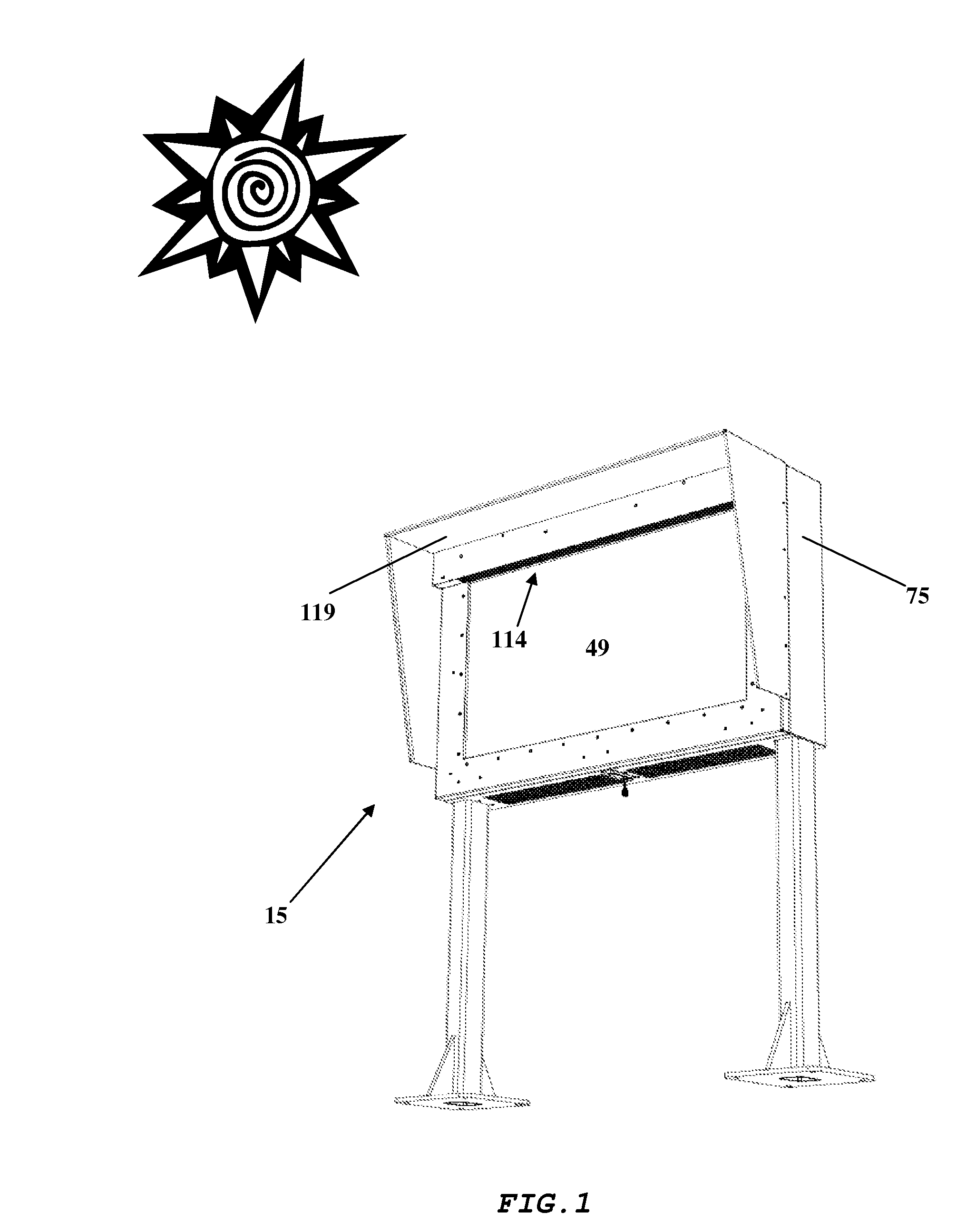

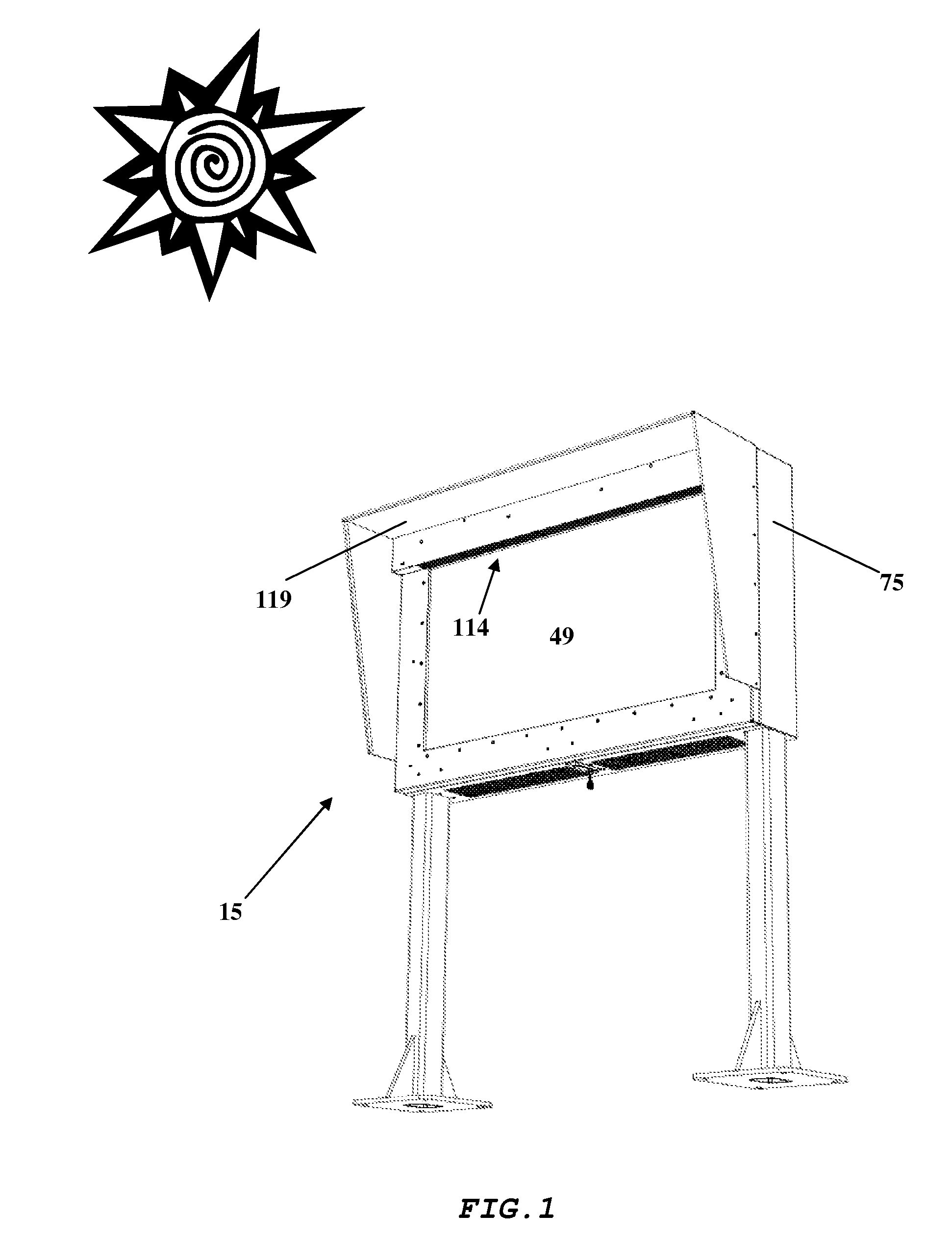

Gas station television

InactiveUS20090129021A1Reduce heatTemperature fluctuationNon-linear opticsCooling/ventilation/heating modificationsImaging qualityNuclear engineering

Preferred embodiments relates to a cooling system and a method for cooling an electronic display. Embodiments include a transparent liquid cooling chamber, a reservoir tank, and a pump. The components in the system are preferably housed within the electronic display housing. The cooling chamber defines a fluid compartment that is anterior to and coextensive with the electronic display surface. Circulating coolant removes heat directly from the electronic display surface by advection. In order to view the display, the coolant fluid is transparent or at least semi-transparent. The image quality of an exemplary embodiment remains essentially unchanged, even though coolant is flowing over the visible face of the electronic display surface.

Owner:MFG RESOURCES INT INC

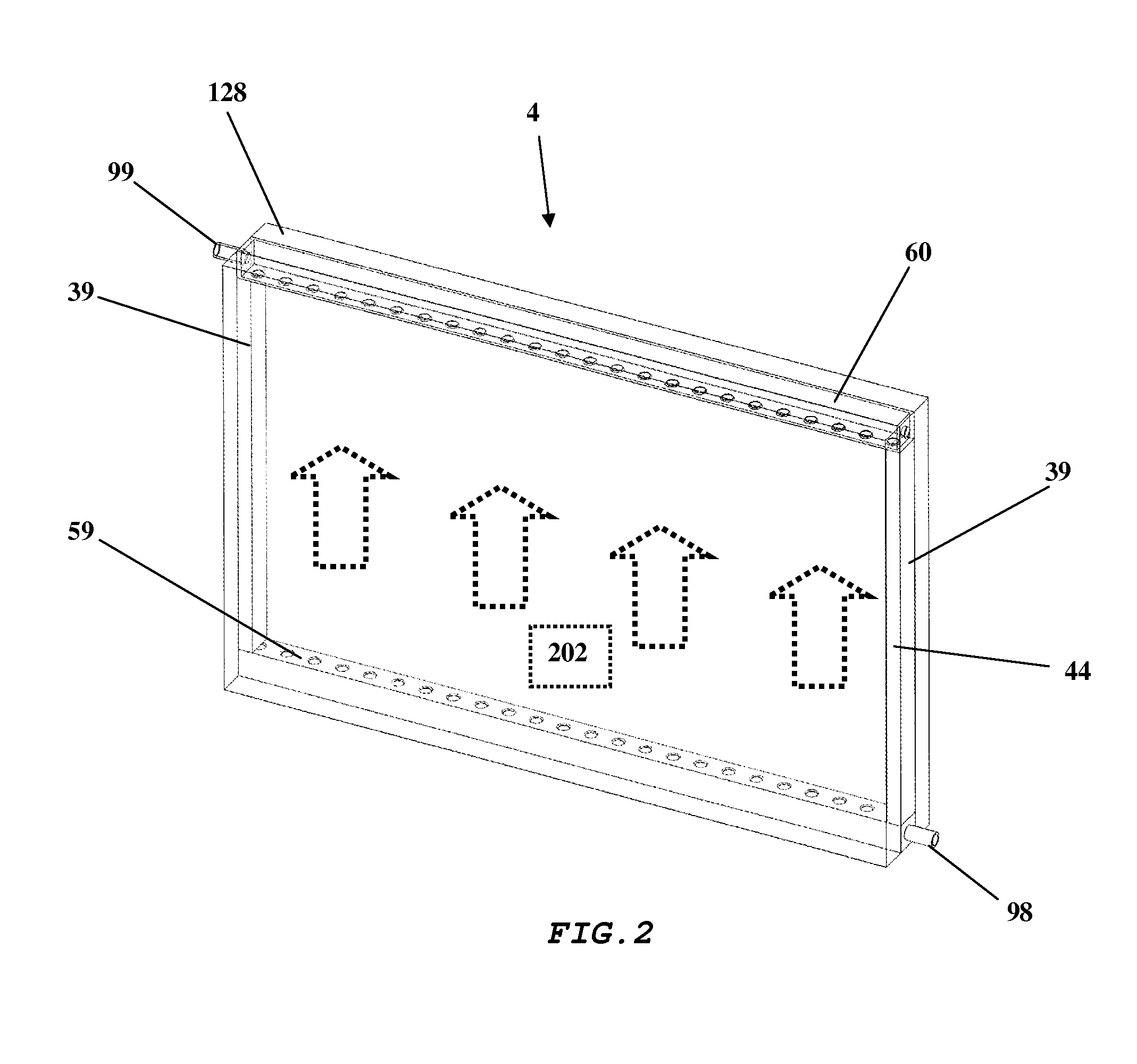

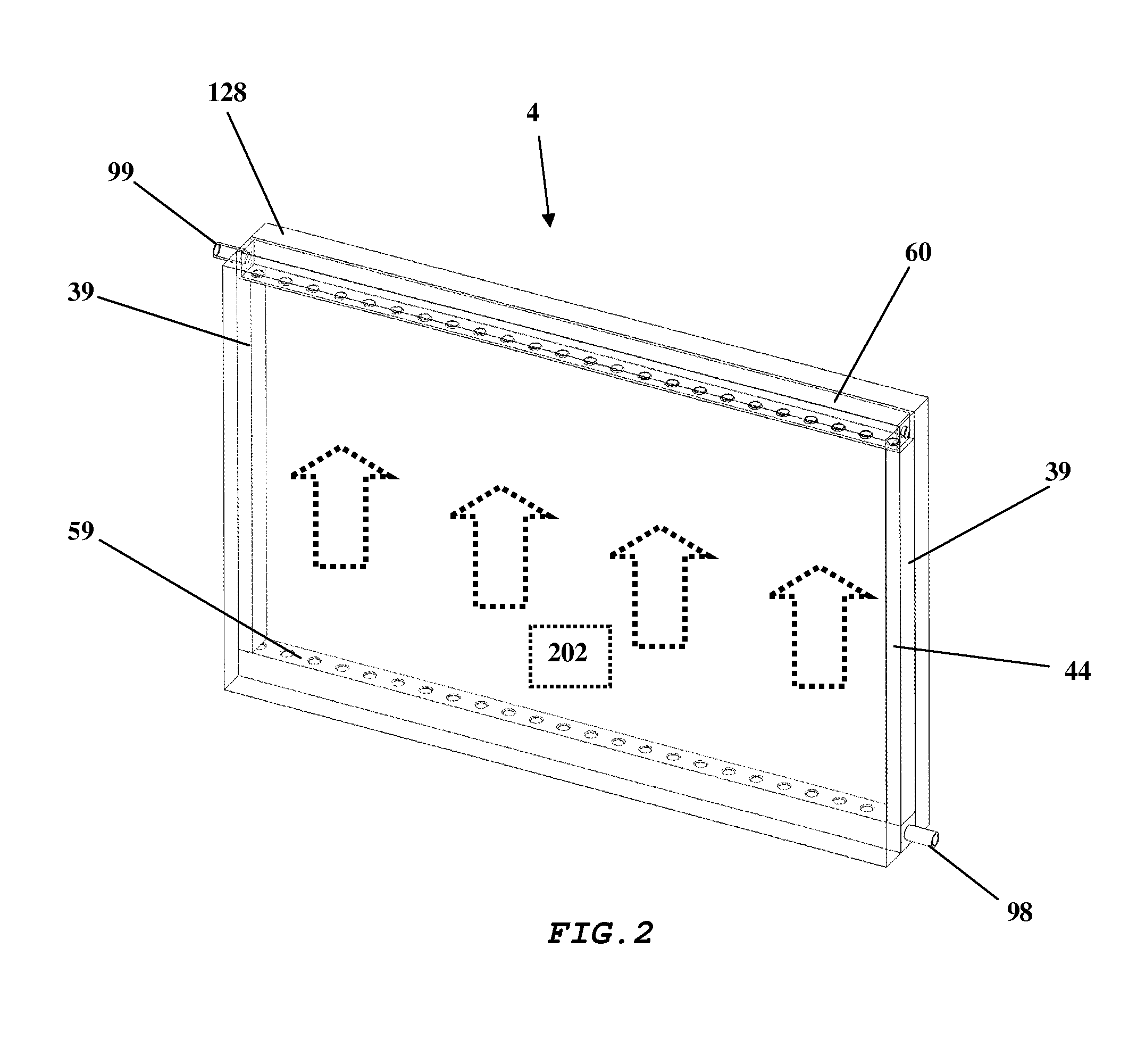

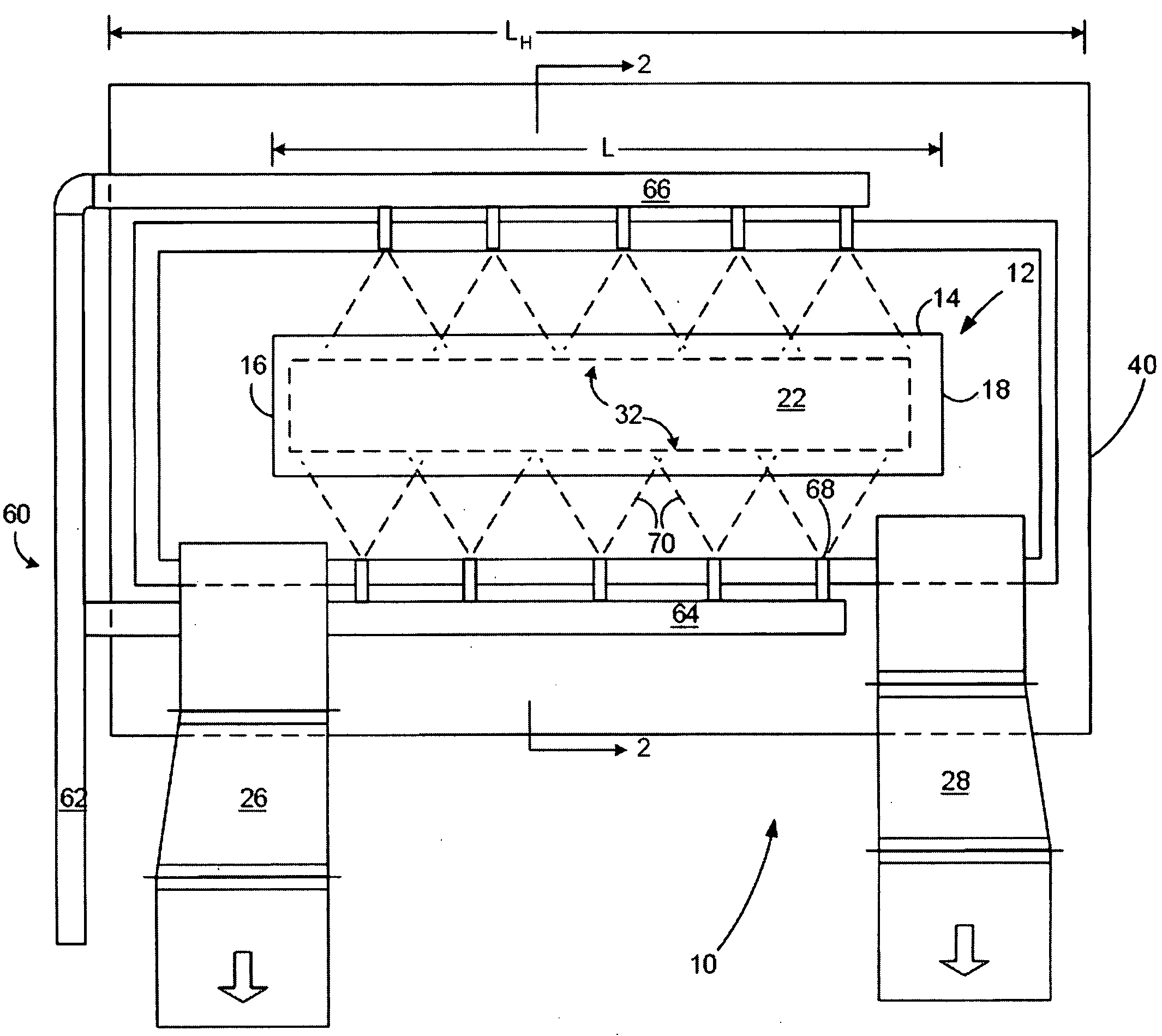

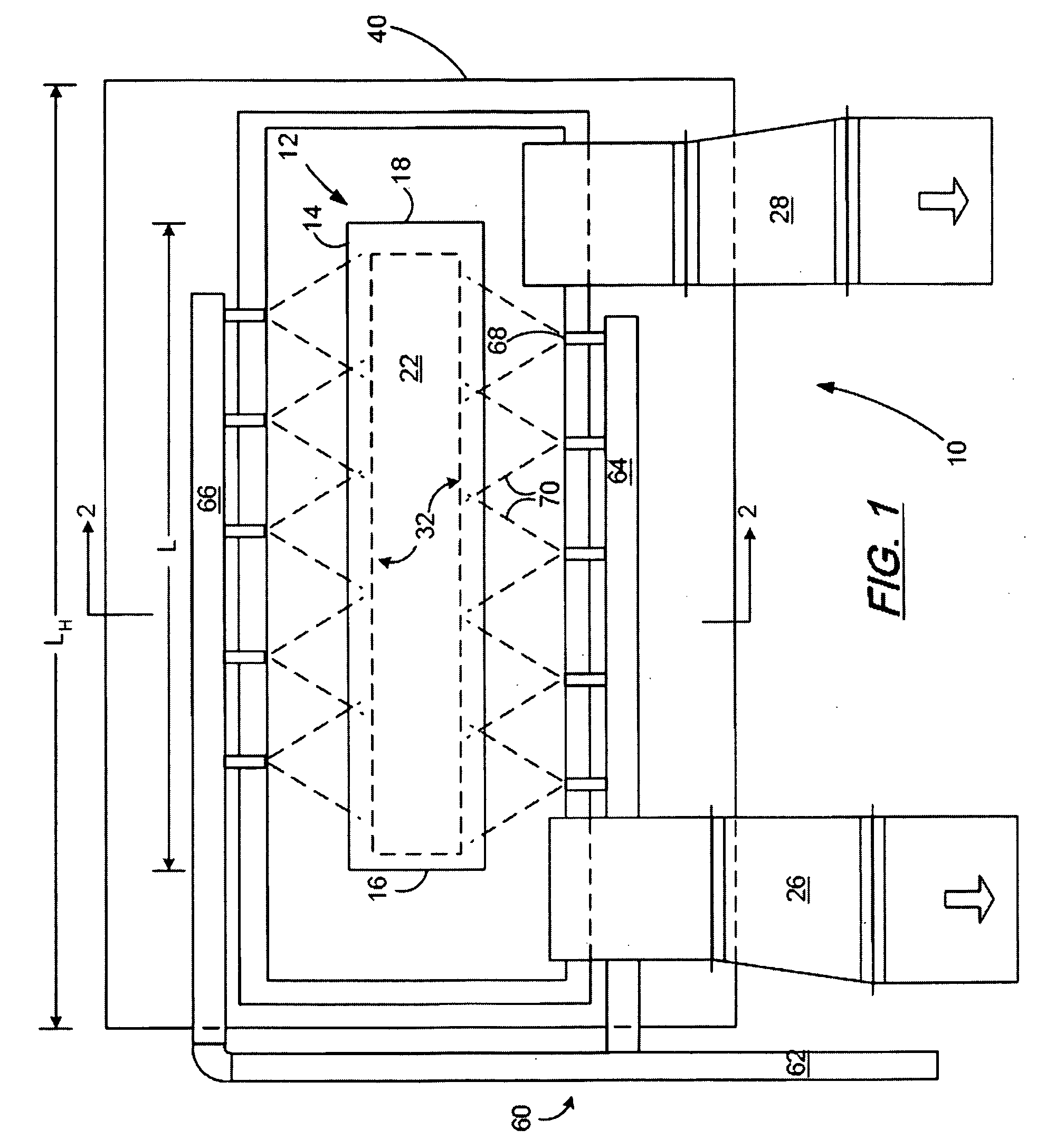

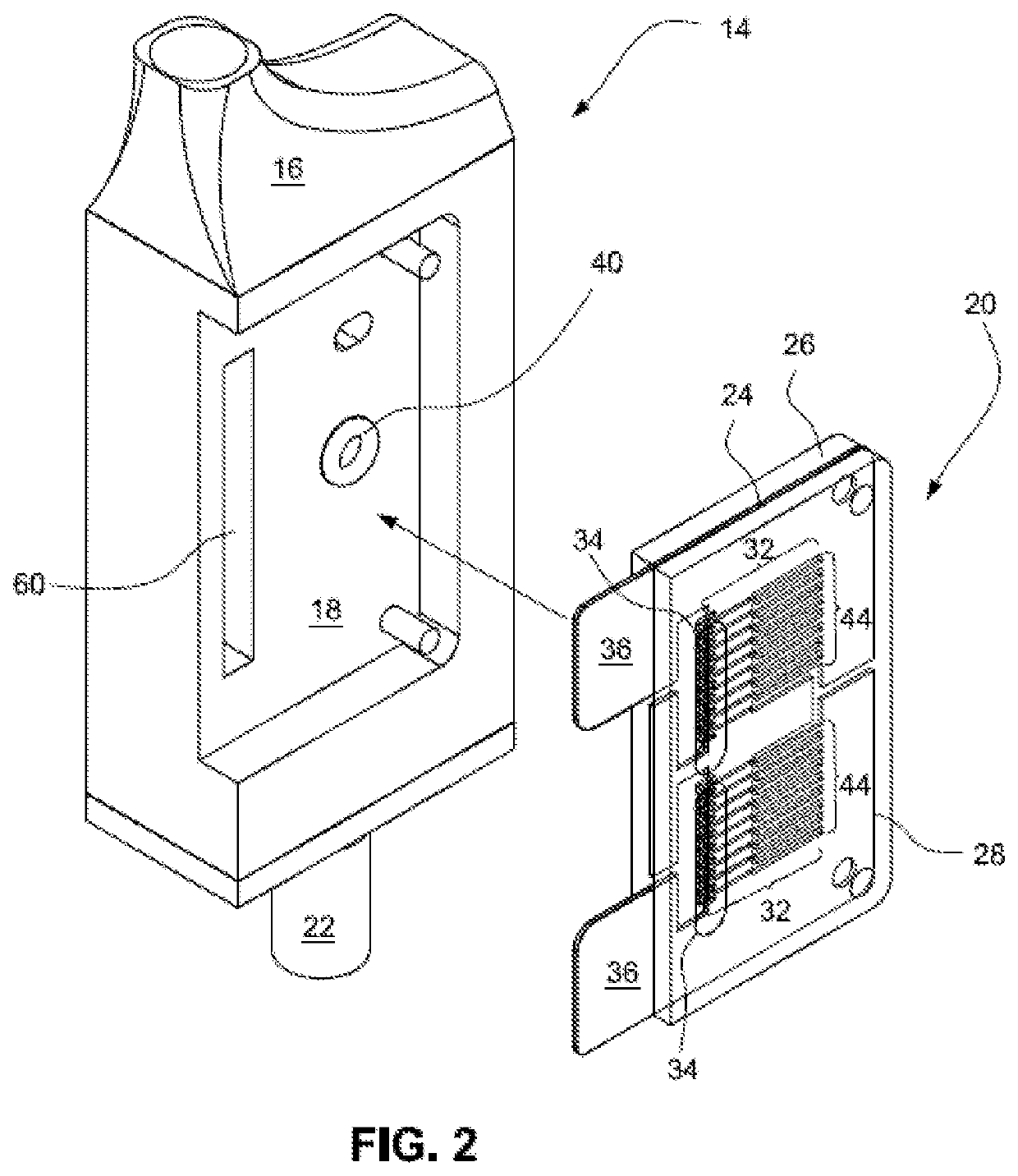

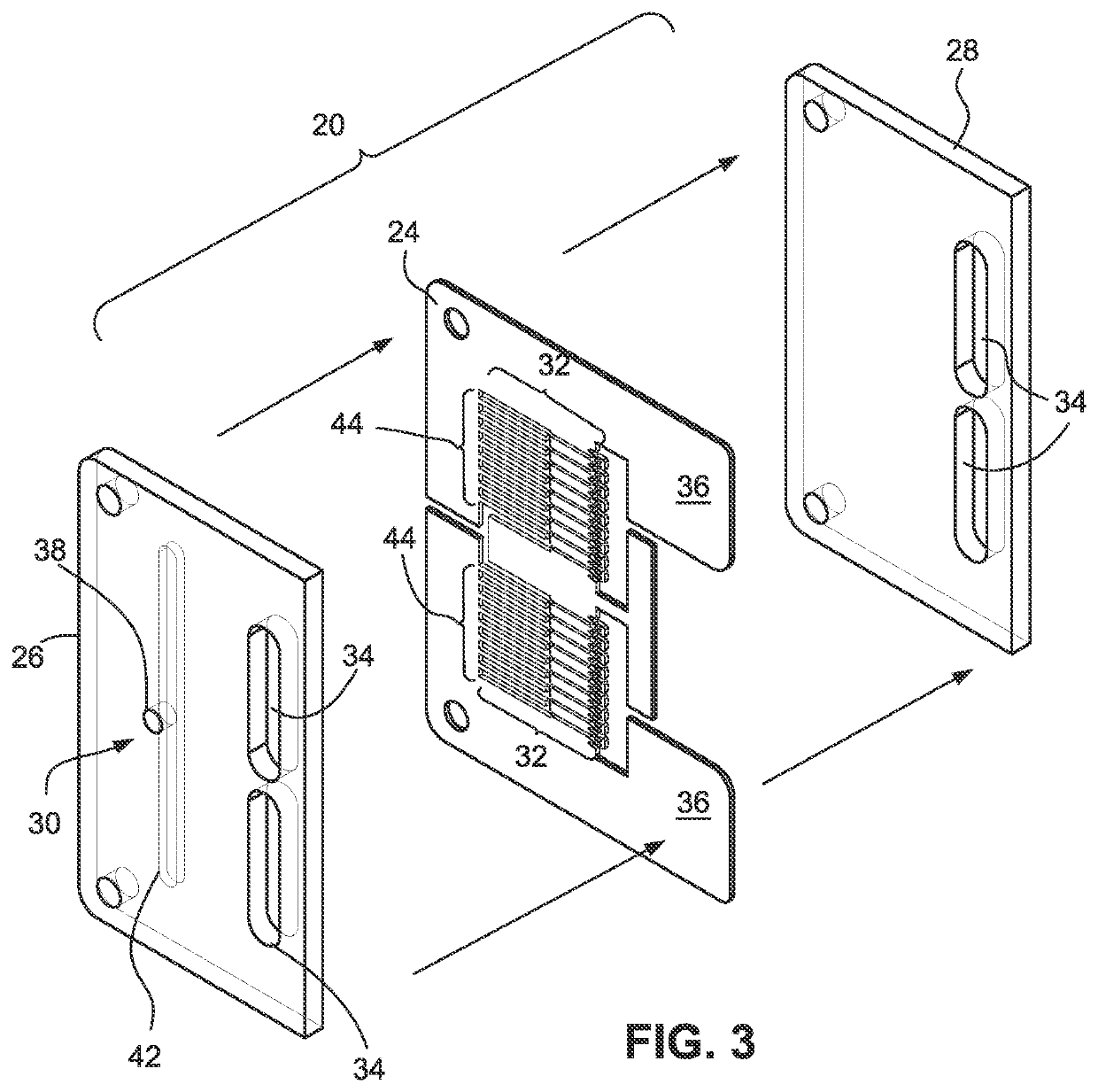

Fluid cooled display

InactiveUS8208115B2Temperature fluctuationImprove cooling effectNon-linear opticsCooling/ventilation/heating modificationsFluid compartmentsImaging quality

Preferred embodiments relates to a cooling system and a method for cooling an electronic display. Embodiments include a transparent liquid cooling chamber, a reservoir tank, and a pump. The components in the system are preferably housed within the electronic display housing. The cooling chamber defines a fluid compartment that is anterior to and coextensive with the electronic display surface. Circulating coolant removes heat directly from the electronic display surface by advection. In order to view the display, the coolant fluid is transparent or at least semi-transparent. The image quality of an exemplary embodiment remains essentially unchanged, even though coolant is flowing over the visible face of the electronic display surface.

Owner:MFG RESOURCES INT INC

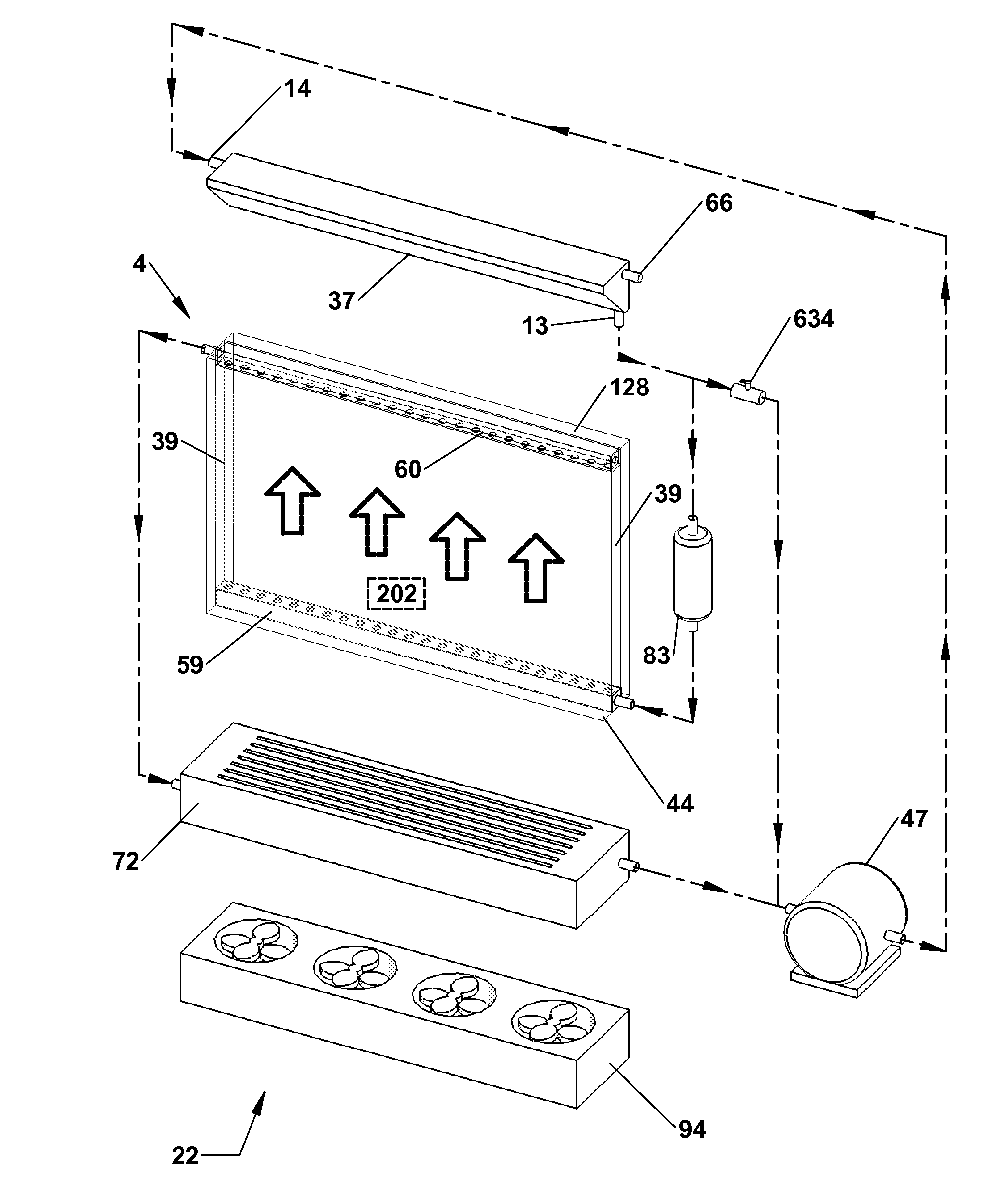

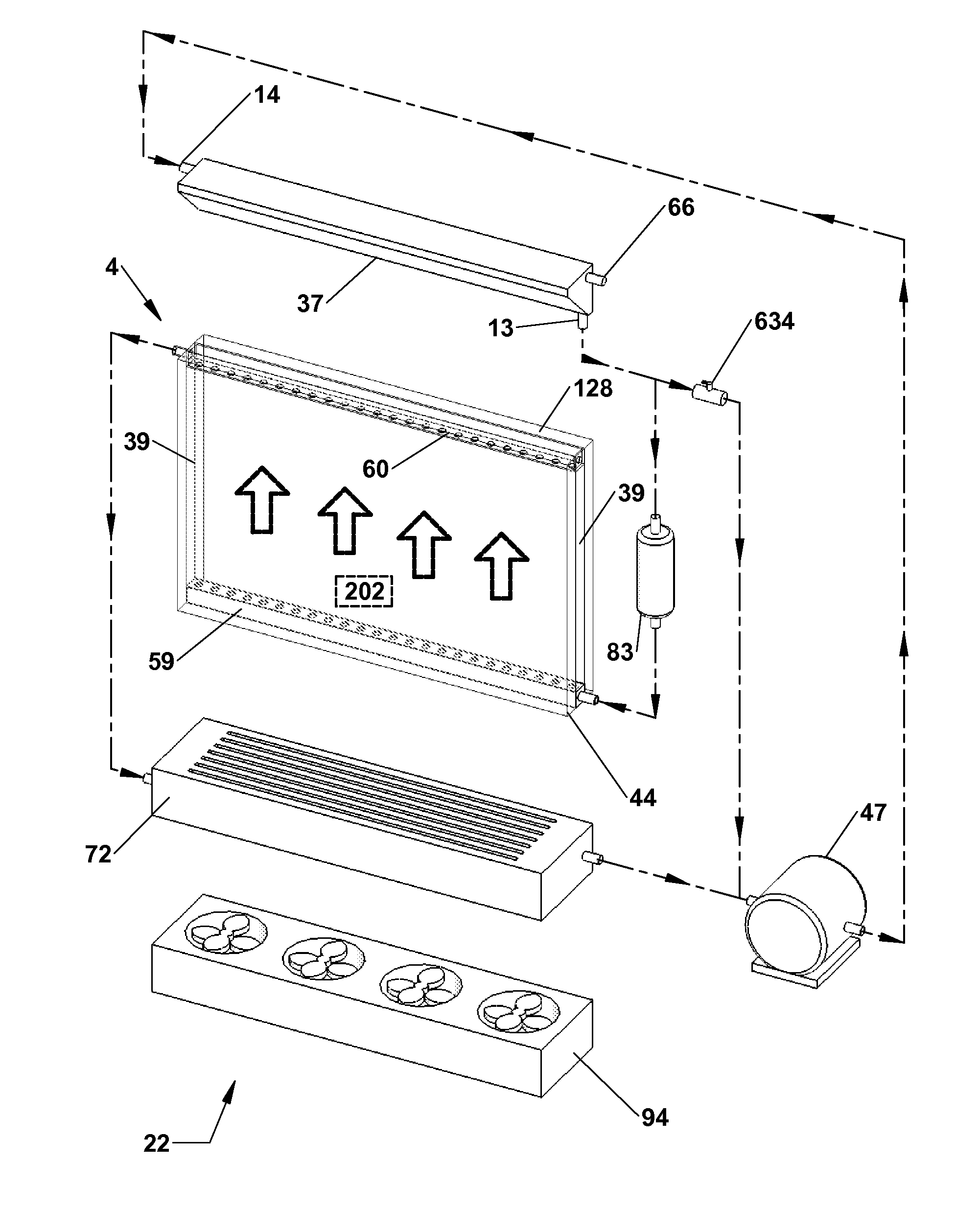

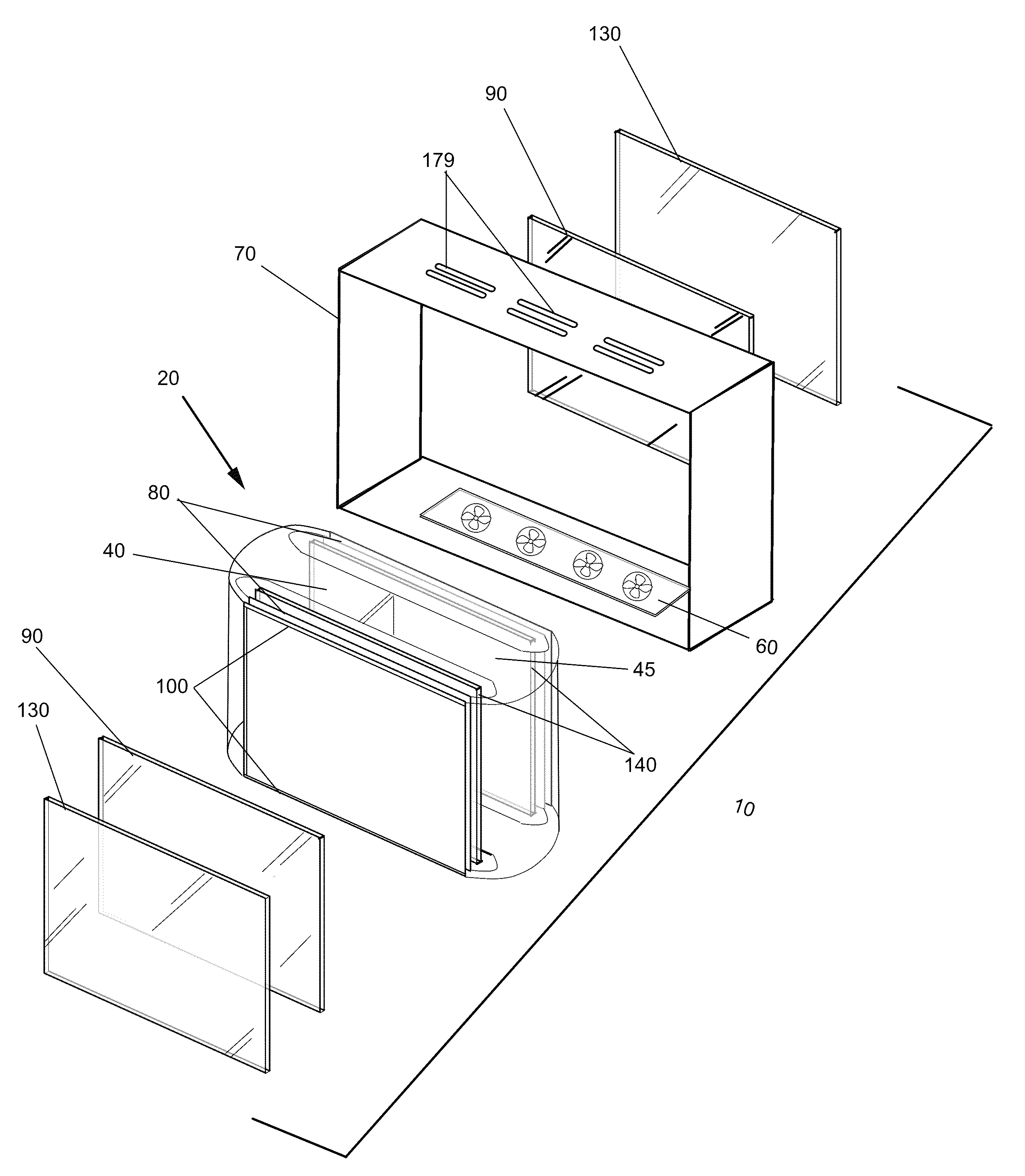

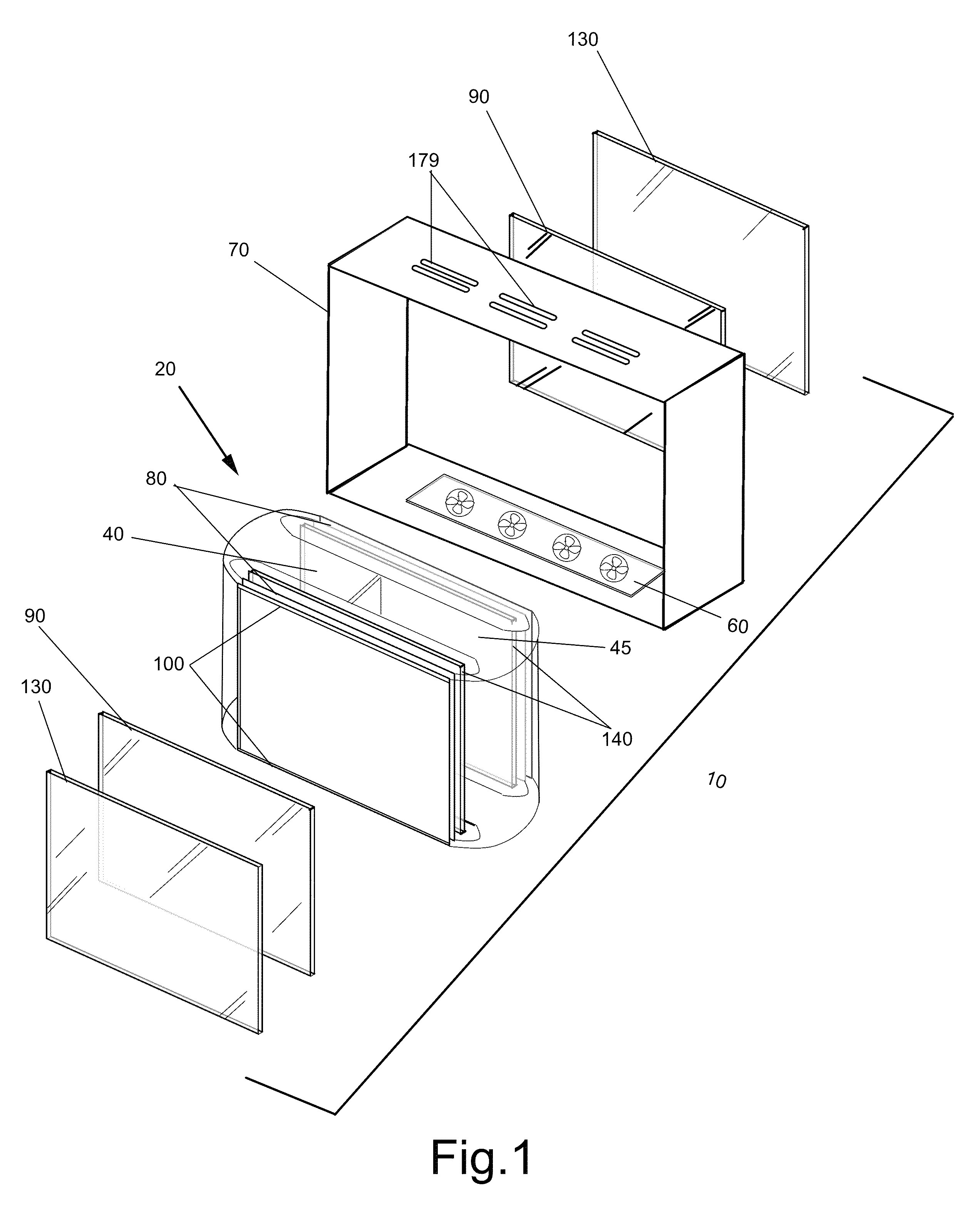

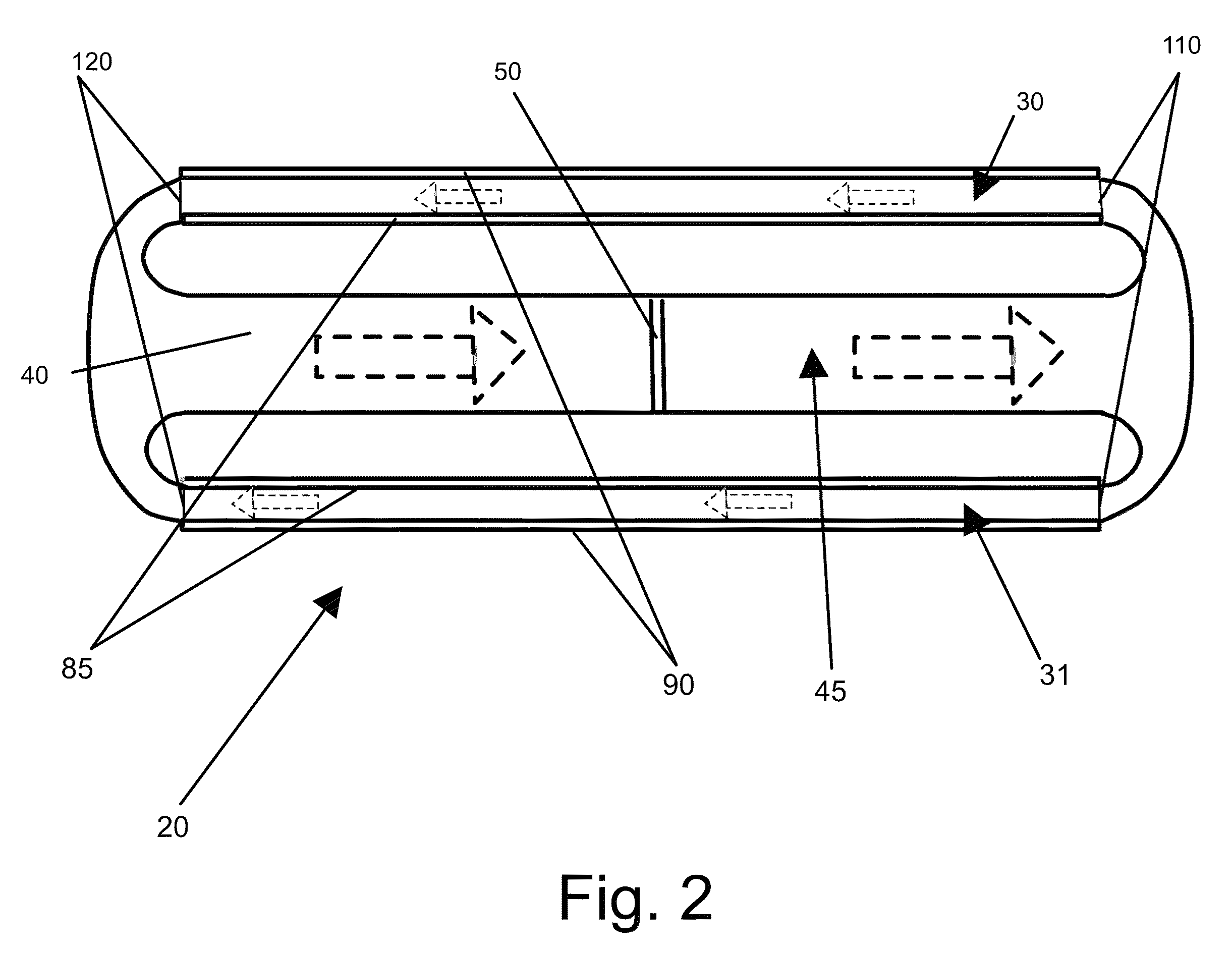

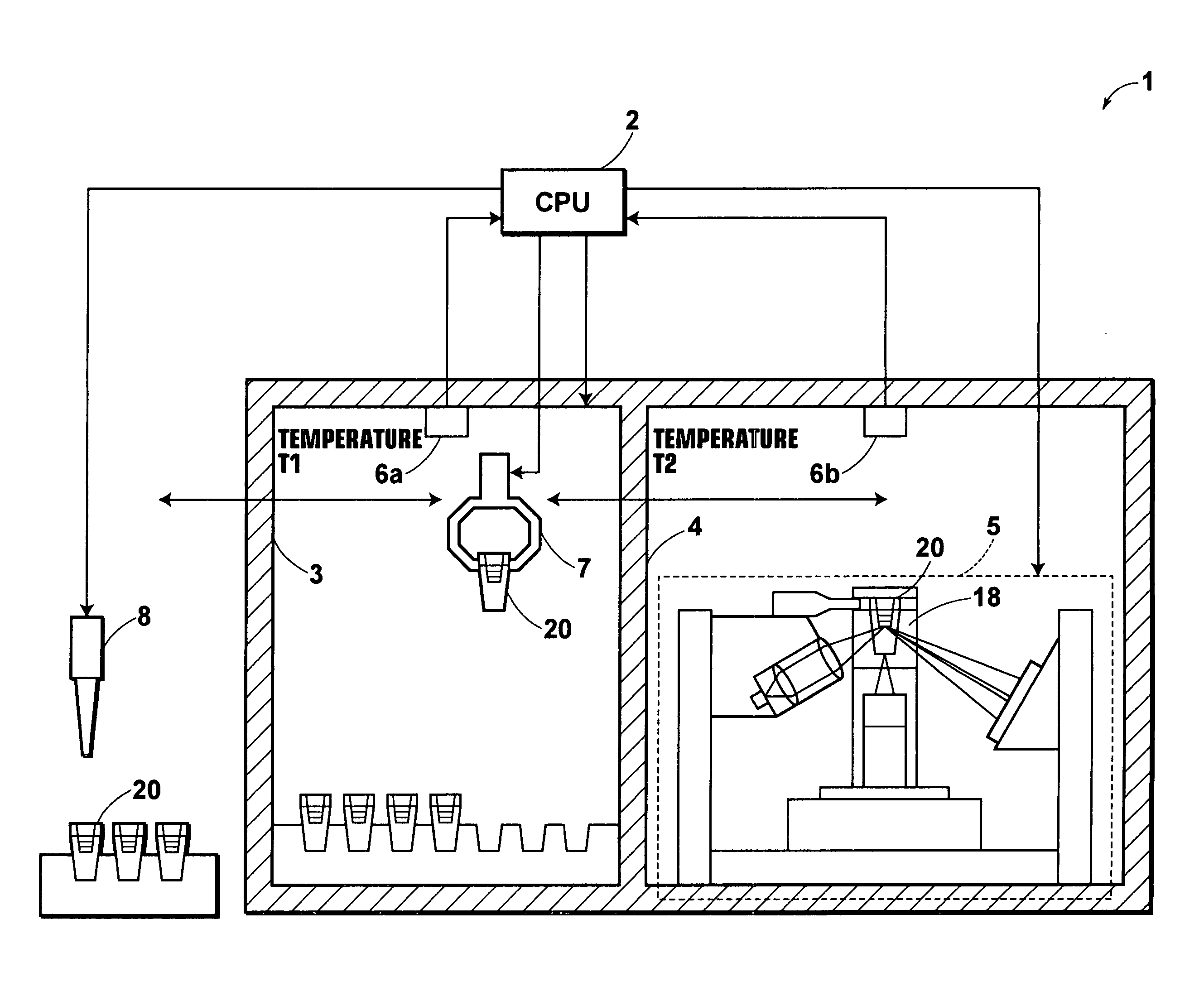

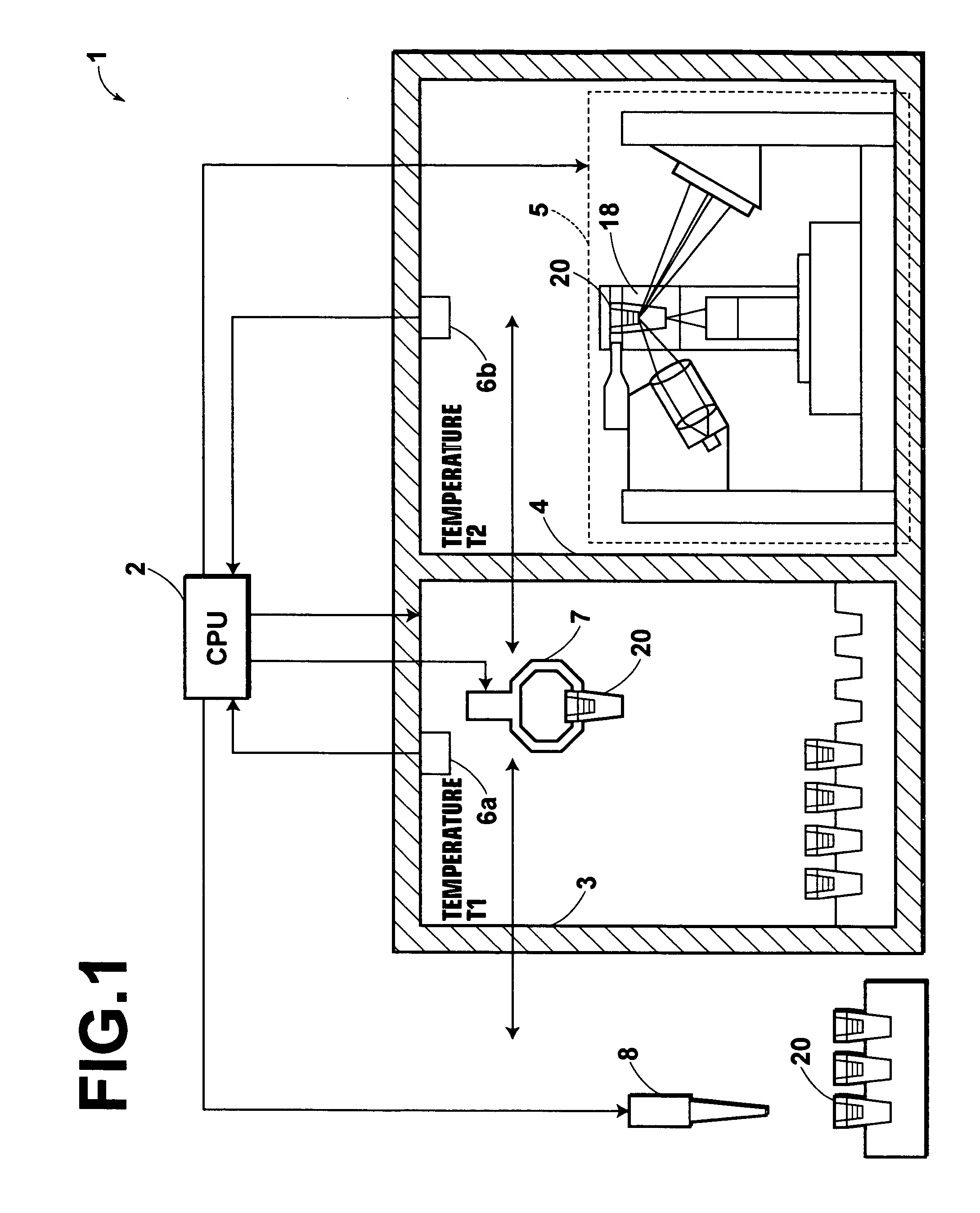

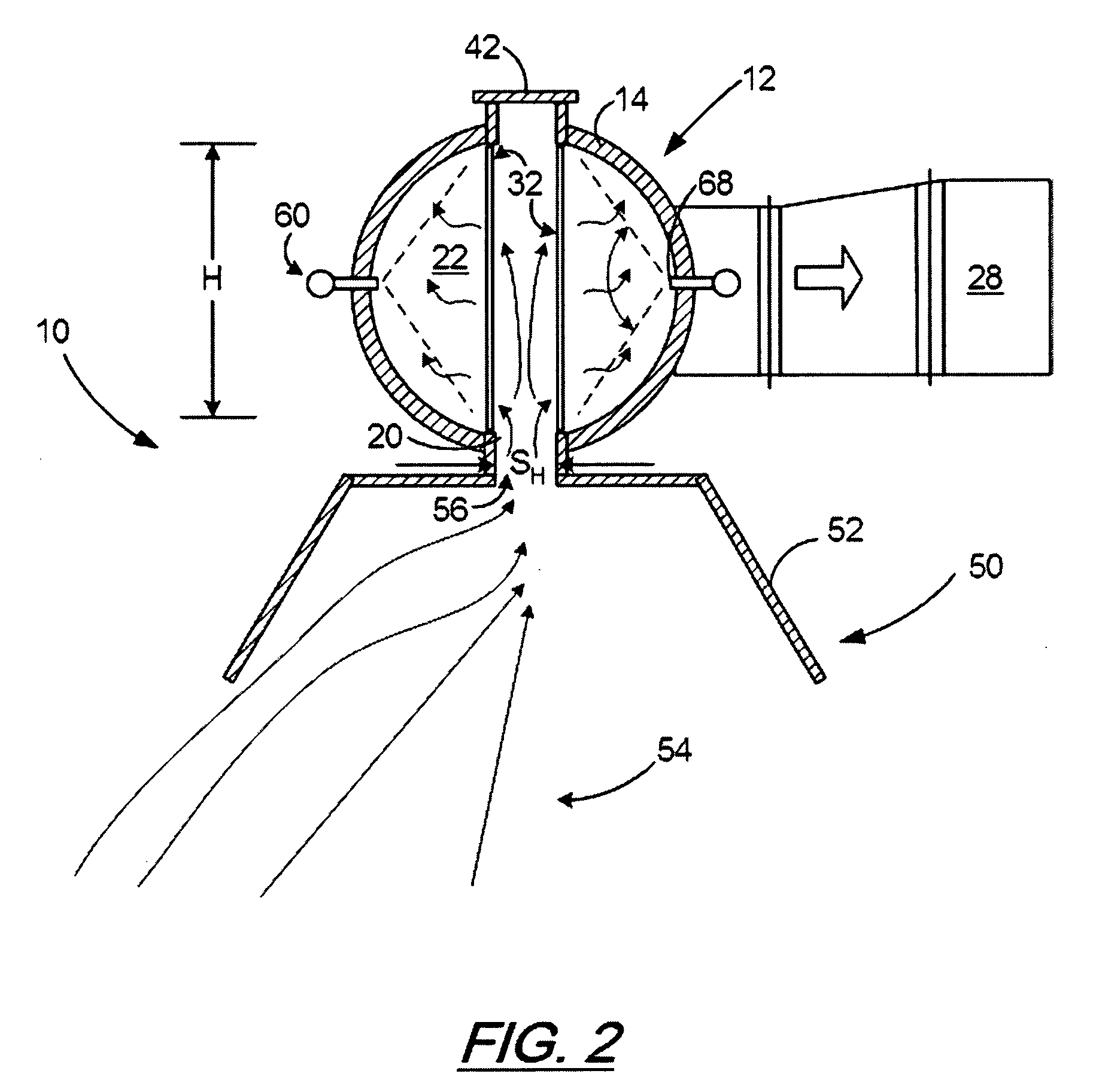

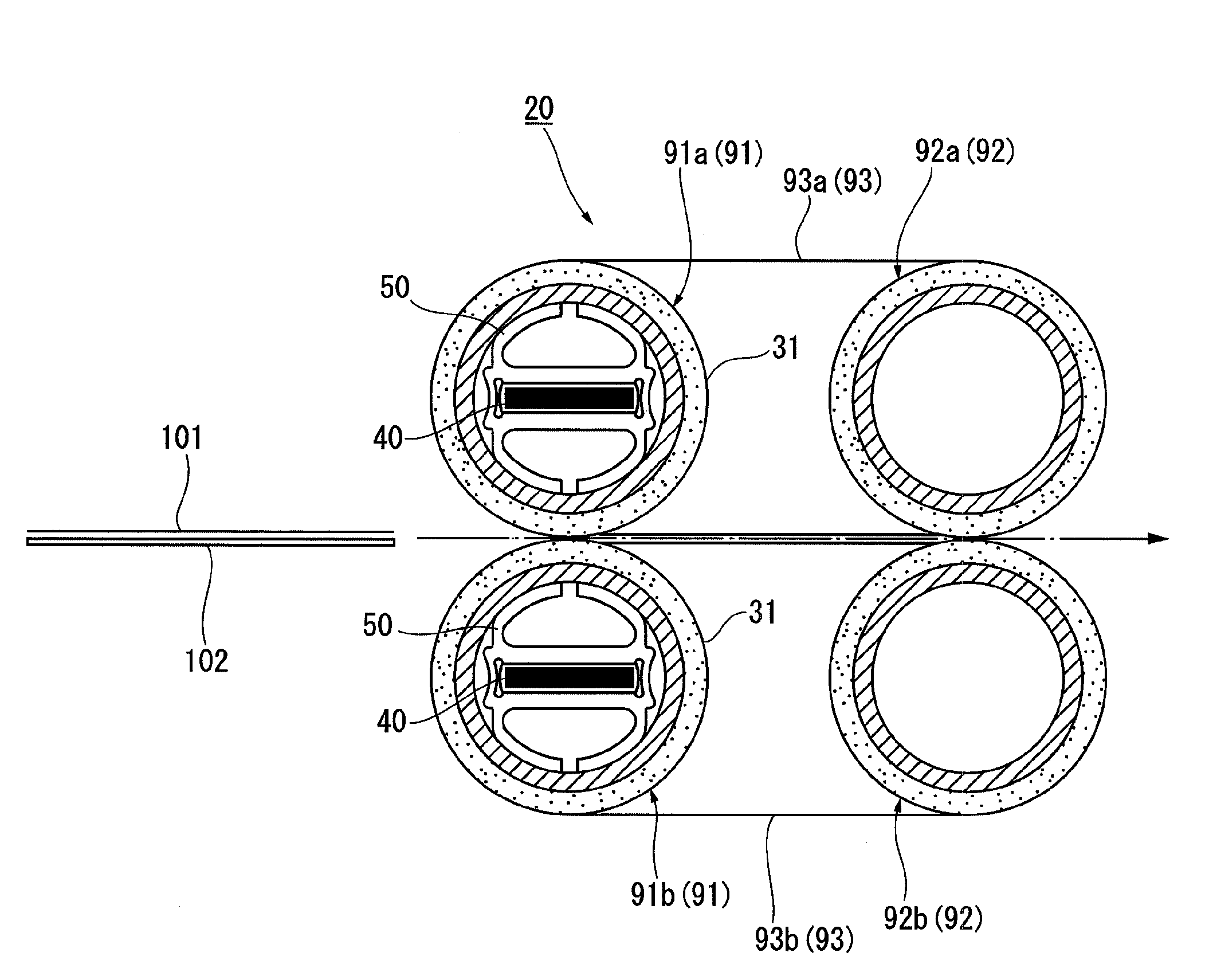

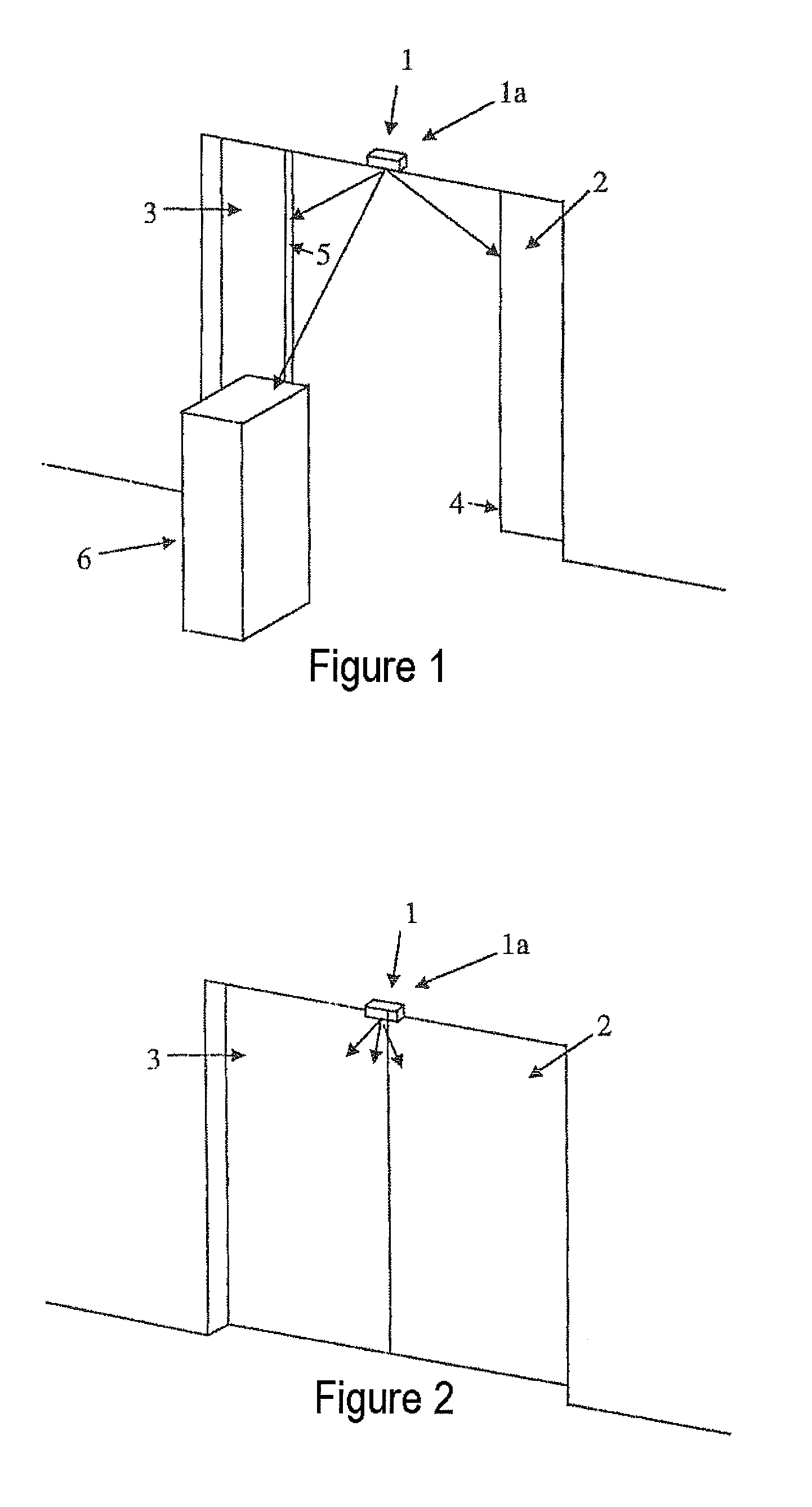

Shared isolated gas cooling system for oppositely facing electronic displays

ActiveUS8373841B2Temperature fluctuationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringImaging quality

A system and method for cooling back to back electronic displays. Transparent first and second gas chambers are co-existive with the front display surfaces of the first and second electronic displays. A closed loop of isolated gas enters the first and second gas chambers and contacts the front surfaces of the electronic displays, where it may extract heat from the front display surfaces. The isolated gas is then directed into a cooling chamber where it is cooled and re-introduced into the first and second gas chambers. Fans may be used to propel the isolated gas through the cooling chamber and the first and second gas chambers. The circulating gas removes heat directly from the electronic display surfaces. The isolated gas is transparent or at least semi-transparent to ensure that the image quality of the electronic displays is minimally impacted.

Owner:MFG RESOURCES INT INC

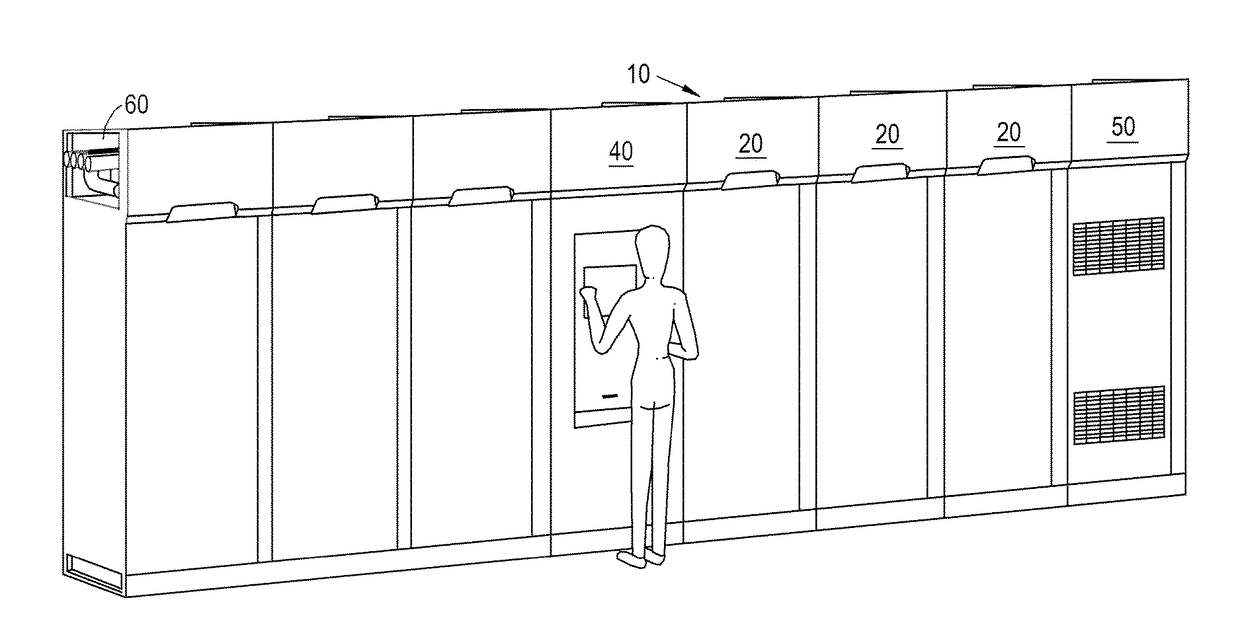

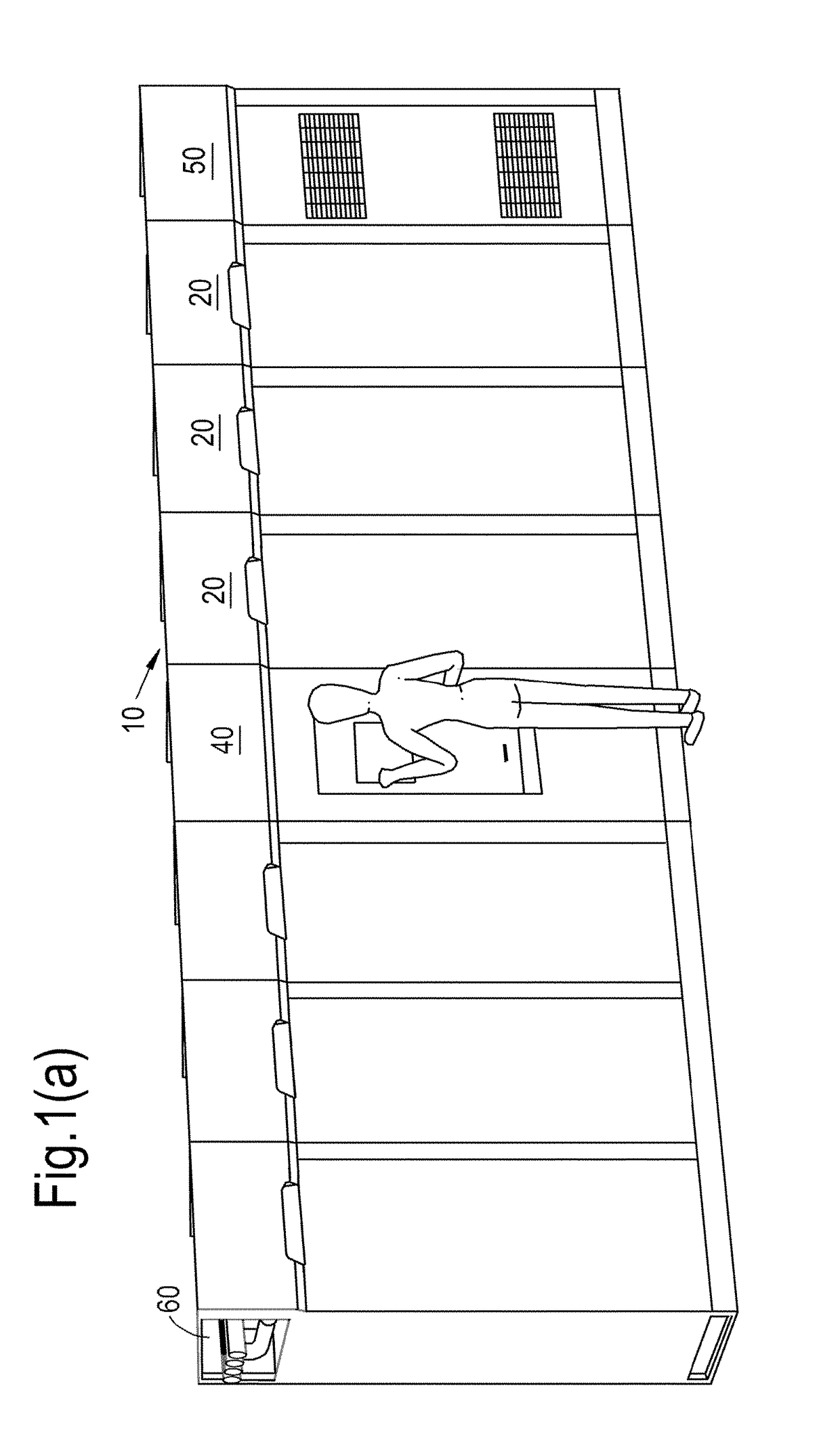

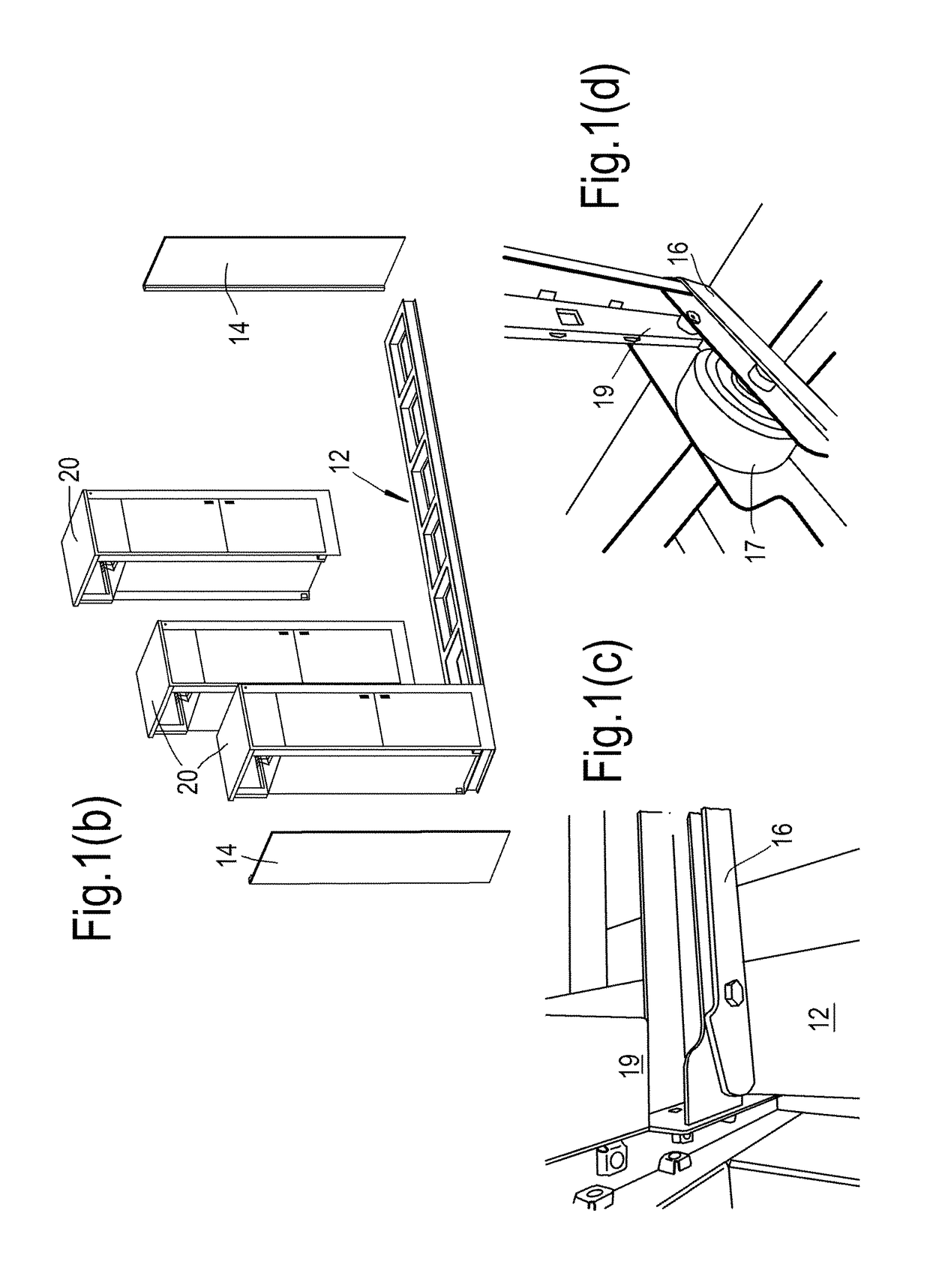

Locker system

ActiveUS20170215620A1Easy and fast switchingEasy to controlKitchen equipmentIndividual entry/exit registersTemperature controlEngineering

A temperature controlled storage apparatus 8(10), comprising; a plurality of lockable storage spaces, each of the plurality of lockable storage spaces comprising one or more compartments; in which the temperature of each of the one or more compartments is independently controllable to provide either one of: chilled temperature; or frozen temperature; and wherein access to the storage space is remotely programmable.

Owner:ILLINOIS TOOL WORKS INC

Surfactant compositions and formulations with a high oil content

ActiveUS20150297489A1Large amount of oilTemperature fluctuationCosmetic preparationsBiocideChemistryOil content

Owner:EVONIK OPERATIONS GMBH

Toner for developing electrostatic image, production method thereof, resin particle dispersion, and electrostatic image developer

Provided are a toner for developing an electrostatic image comprising a crystalline resin having an ester bond and at least one of a sulfide bond or a disulfide bond in the main-chain, an electrostatic image developer and an image-forming process by using the same, a method of producing the toner for developing electrostatic image, and a resin particle dispersion using the same.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Surfactant compositions and formulations with a high oil content

InactiveUS20150297485A1Large amount of oilTemperature fluctuationCosmetic preparationsBiocideOil contentOrganic chemistry

Owner:EVONIK DEGUSSA GMBH

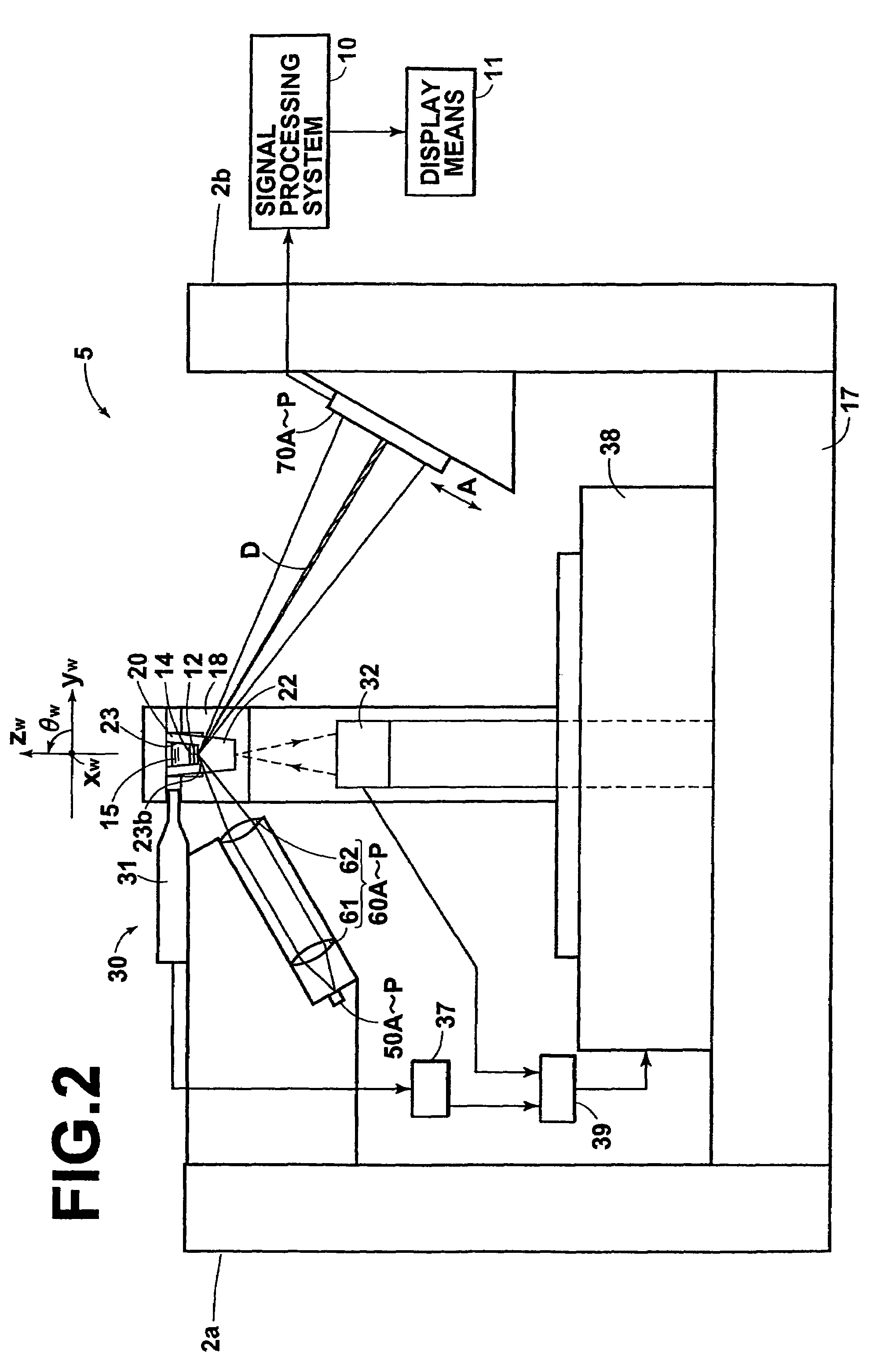

Measuring apparatus

InactiveUS7144153B2Measurement is droppedHigh measurement accuracyThermometer detailsPhase-affecting property measurementsDielectricMeasuring instrument

In a surface plasmon resonance sensor, a sensor unit includes a dielectric block, a thin film layer which is formed on the upper surface of the dielectric block, and a sample holding portion. An incubator is provided, the surface plasmon resonance sensor is spatially isolated from the surroundings by placing it in the measuring system, the temperature of the measuring system is measured and temperature change of the sensor unit after it is conveyed to the measuring system from the incubator is estimated on the basis of the temperature difference between the temperature of the incubator and the temperature of the measuring system, and the sensor unit is conveyed to the measuring system to perform the measurement within a time for which the temperature of the sensor unit does not unacceptably change.

Owner:FUJIFILM HLDG CORP +1

Cleanable in situ spark arrestor

ActiveUS20100229727A1Prevent escapeCollect dustCombination devicesAuxillary pretreatmentAirflowWedge shape

A system for reducing the occurrence of fires in a fabric filter dust collection system. The system includes an elongated housing having a first end and a second end distal from the first end. A gas flow inlet is provided in flow communication with an interior portion of the housing for flow of gas and particulates from a source into the housing. A gas flow outlet is provided in flow communication with the housing for flow of gas and particulates out of the housing and into the dust collection system. An elongated spark arrestor is disposed in the housing between the first end and the second end. The spark arrestor has a plurality of spaced-apart, wedge-shaped members having a gap between adjacent members sufficient to interrupt the flow of combustible particles from the source to the dust collection system.

Owner:SUNCOKE TECH & DEV LLC

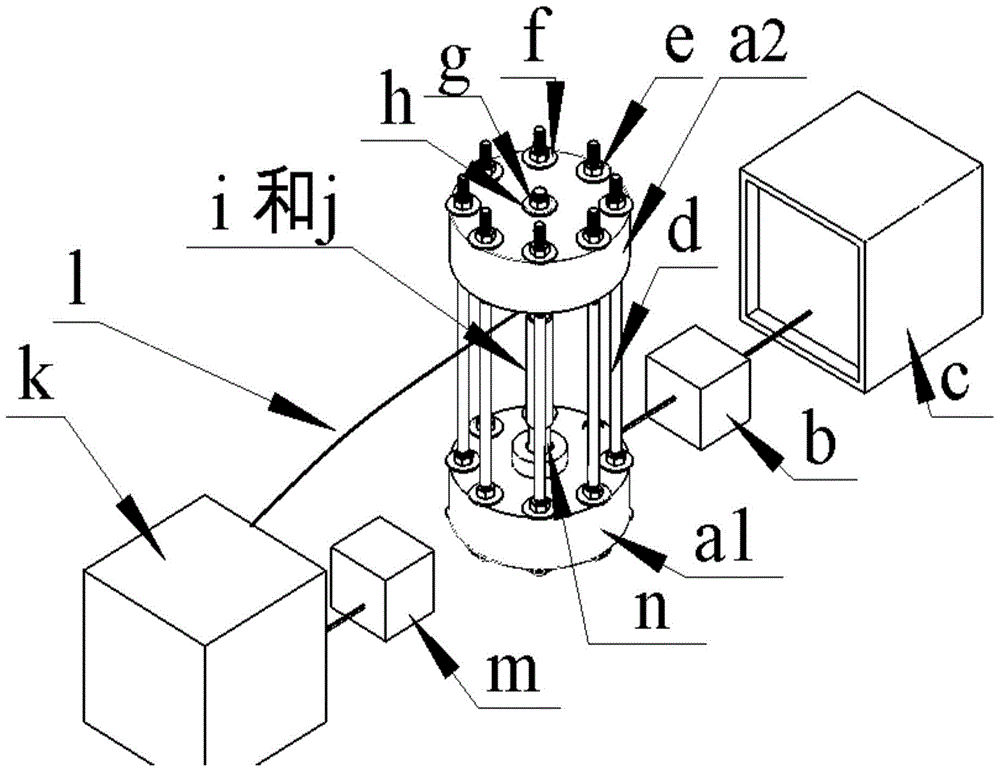

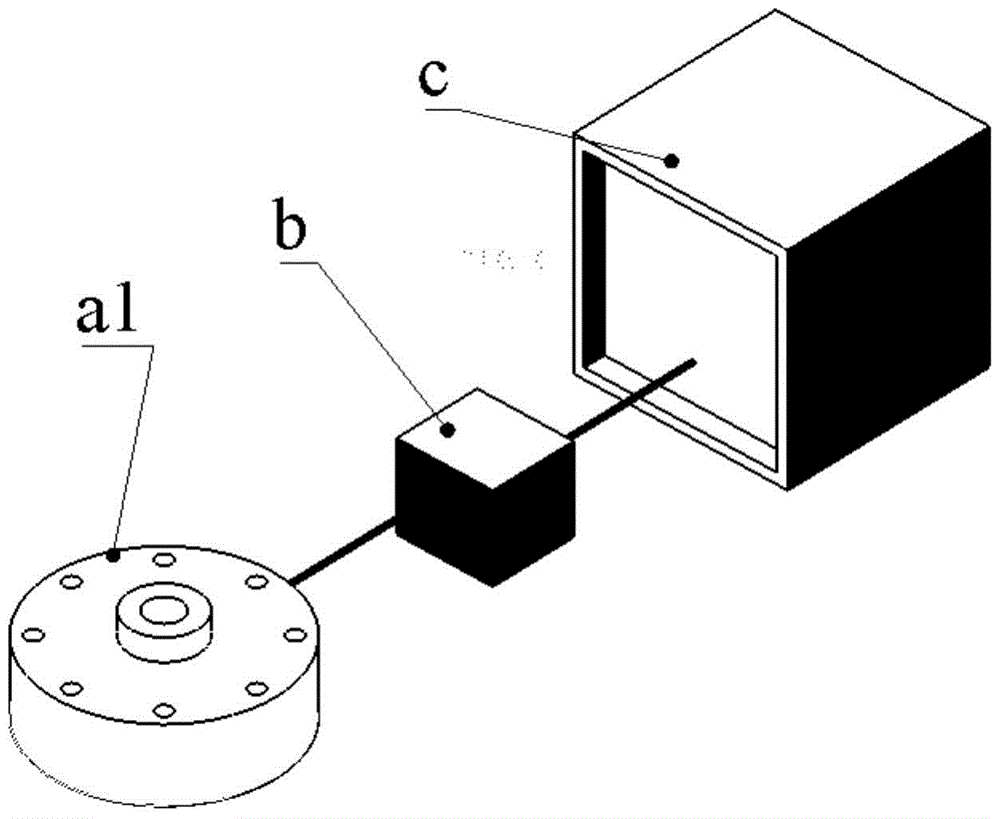

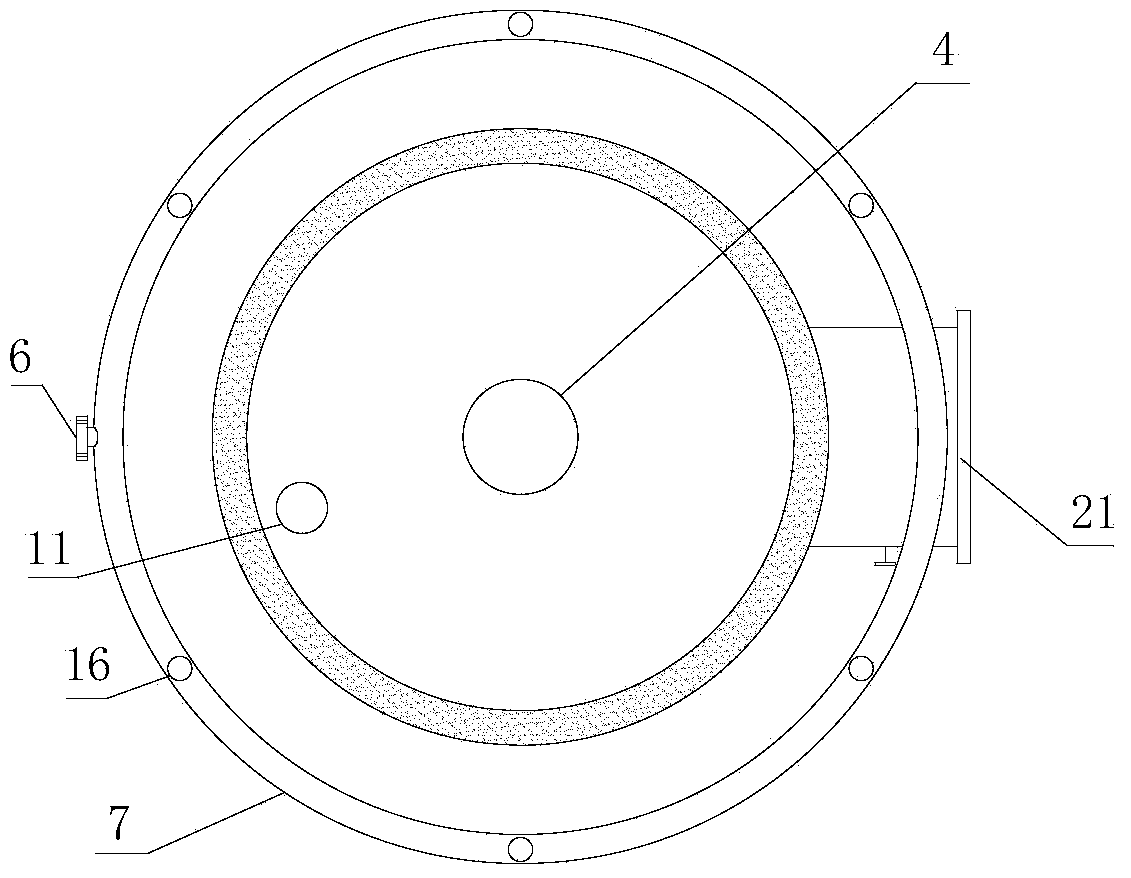

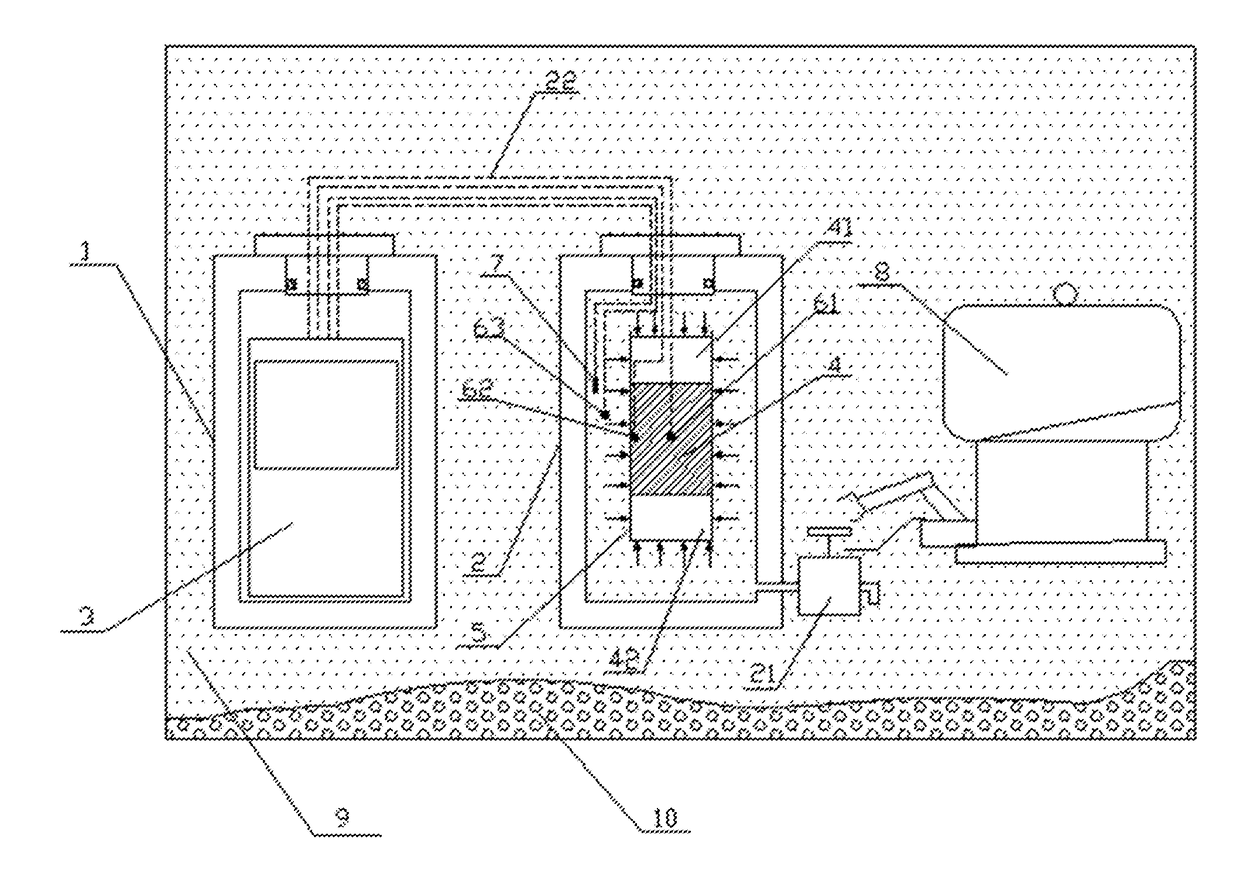

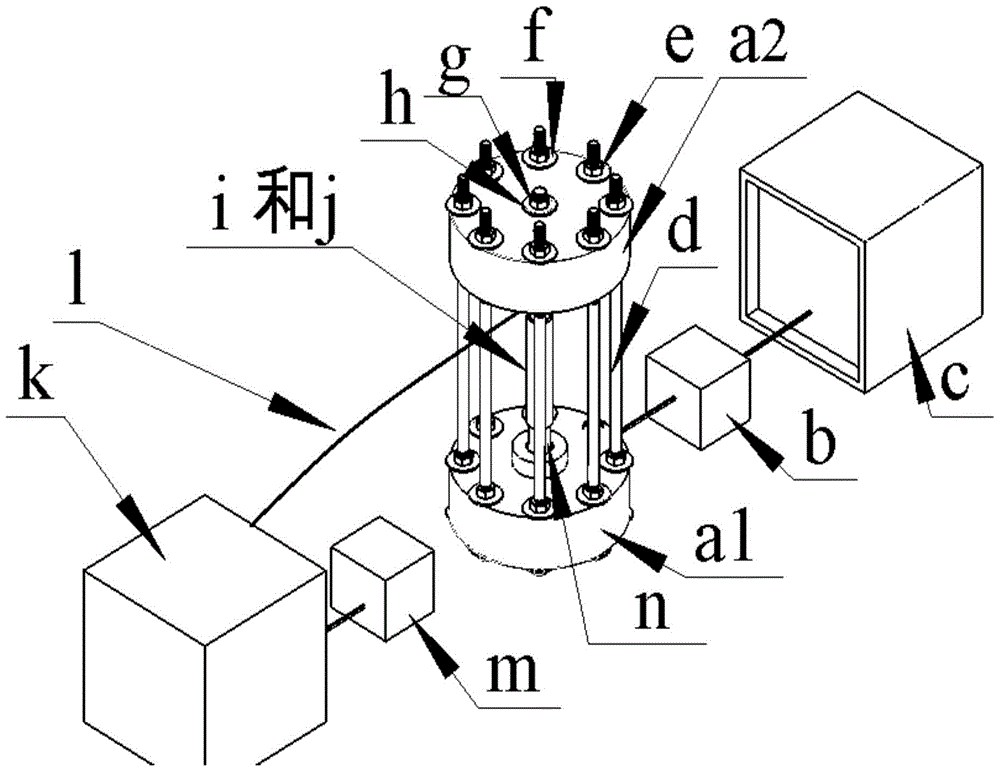

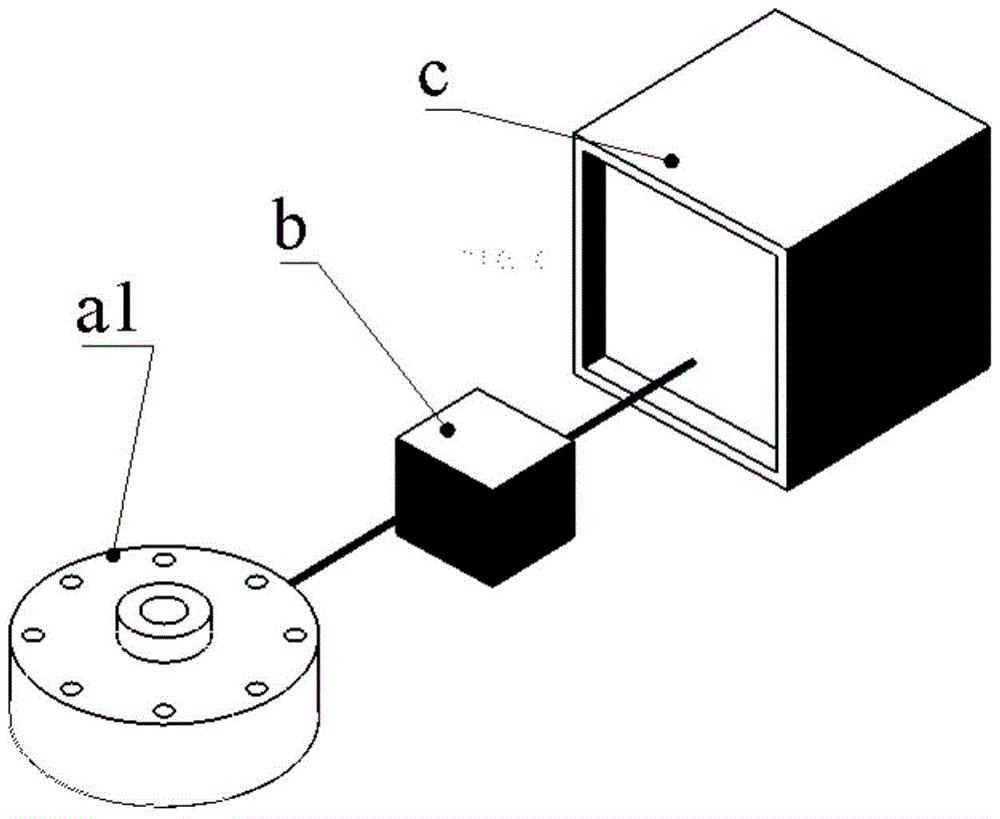

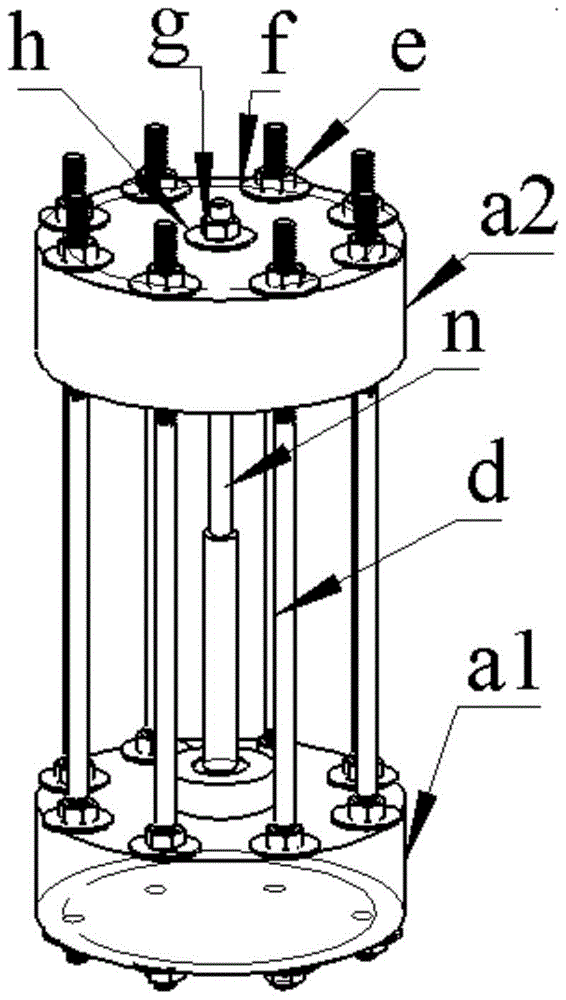

Bolt pre-tightening force degradation process real-time detection device considering high-temperature creep

ActiveCN105043741ARecord degradation data in real timeEasy to assembleMachine part testingMeasurement of torque/twisting force while tighteningMaterials testingEngineering

The invention relates to a bolt pre-tightening force degradation process real-time detection device considering high-temperature creep. The detection device includes a pre-tightening force acquisition system (A), a bolt clamping connecting device system (B) and a heating system (C), wherein the three systems are connected with one another. The detection device has the advantages of low construction cost, small size, portable convenience and convenience in high temperature creep simulation under real conditions. With the bolt pre-tightening force degradation process real-time detection device adopted, a high temperature environment can be provided, so that a creep process of a bolt in a use process can be accurately simulated, and at the same time, the numerical value of a pre-tightening force can be acquired in real time and can be fed back to a computer. The detection device has a bright application prospect in the engineering material testing apparatus and equipment technical field.

Owner:电科北方数字科技(山东)有限公司

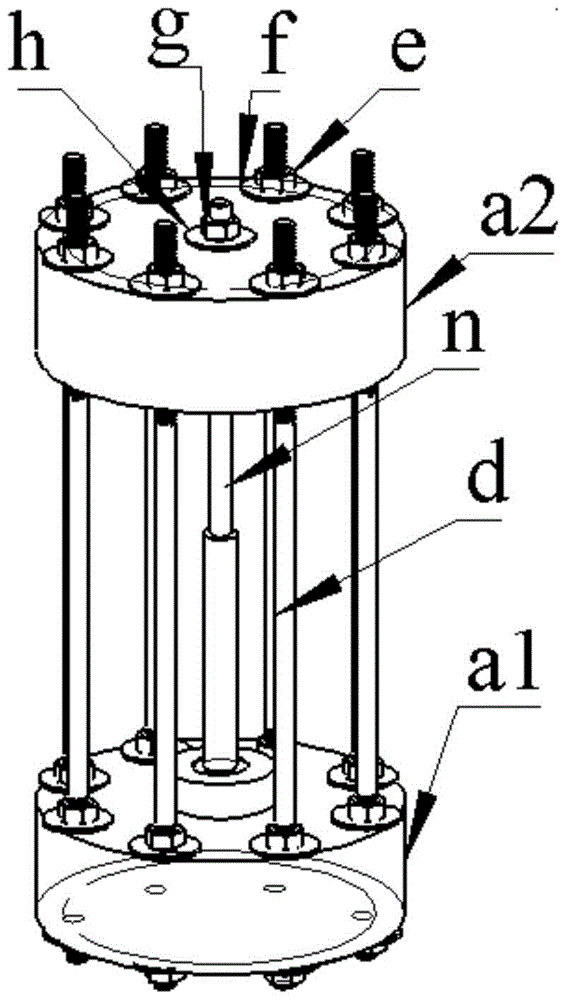

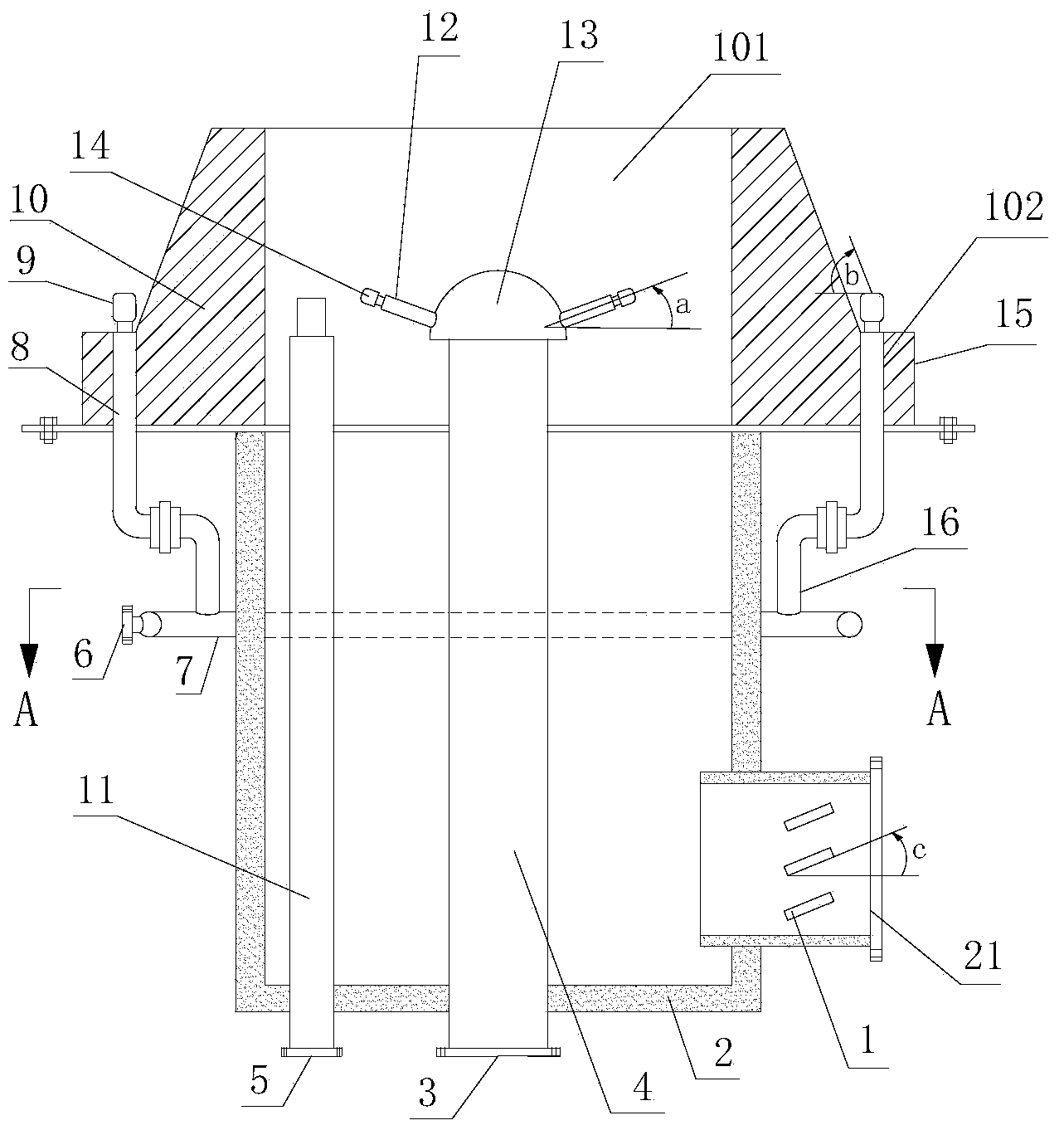

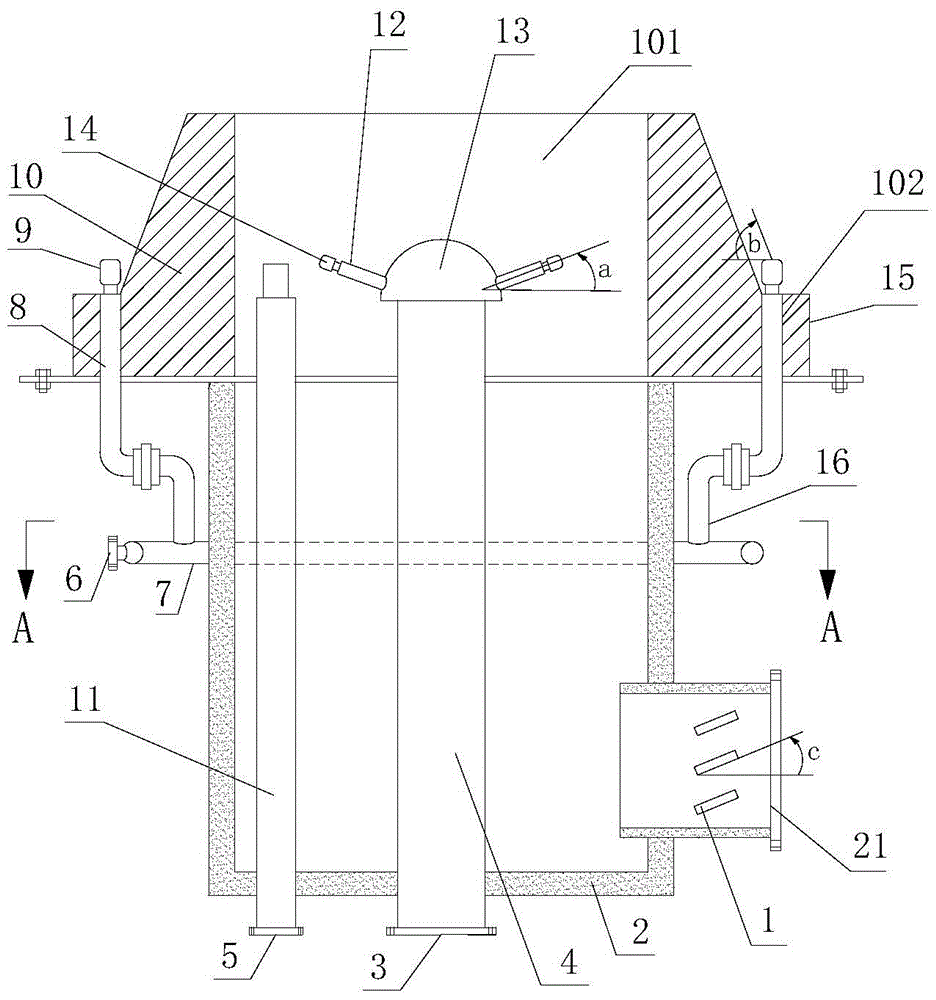

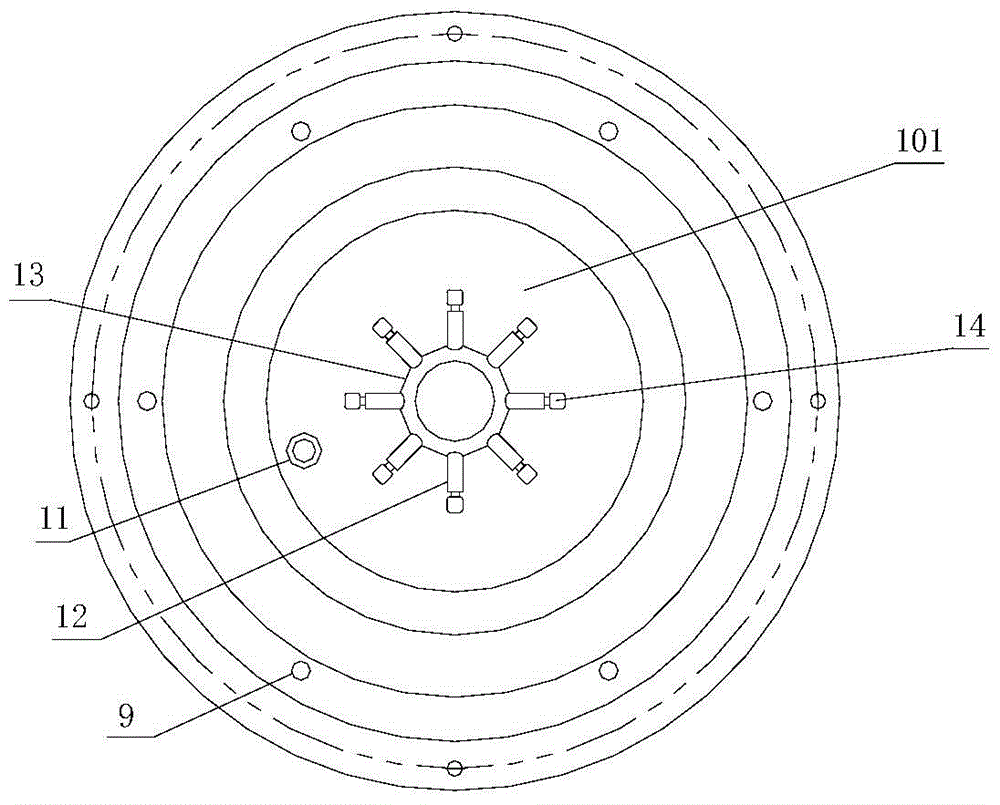

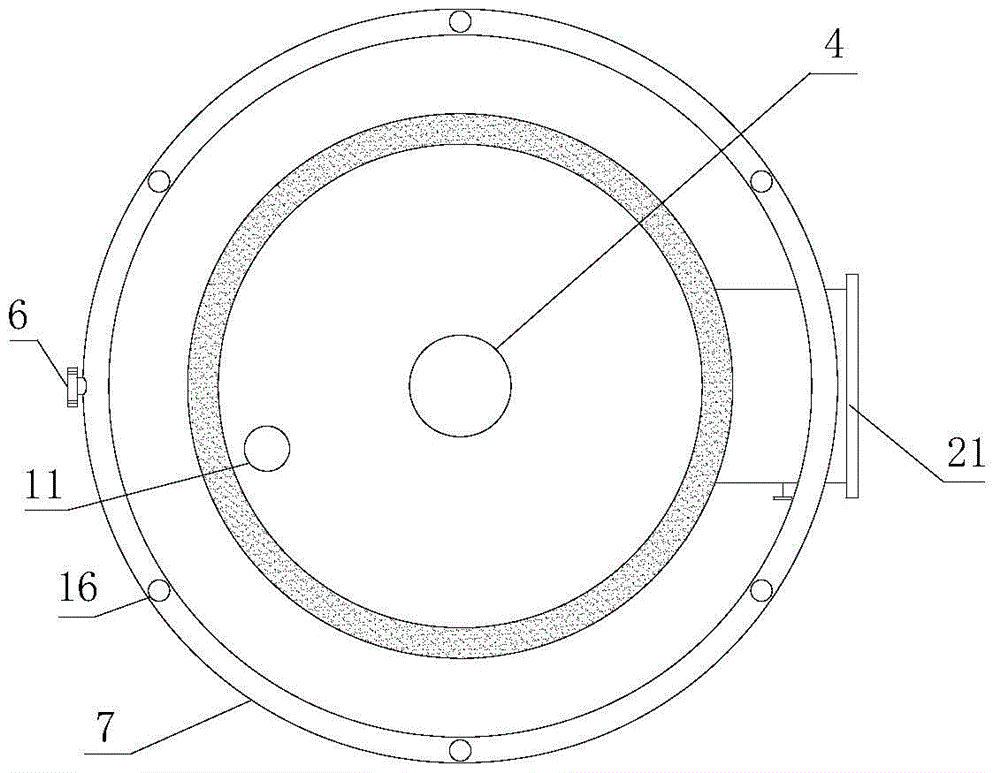

Multi-spray-nozzle bulky combustion low-NOx gas combustor

InactiveCN103471101AEvenly distributedLower combustion temperatureGaseous fuel burnerCombustorFuel distribution

The invention provides a multi-spray-nozzle bulky combustion low-NOx gas combustor, which comprises a heat insulation tile, a first-stage combustor, a second-stage combustor, a first-stage fuel distribution pipe and an air box, wherein a first passage and a second passage are arranged on the heat insulation tile, the lower end of the heat insulation tile is connected with the upper end of the air box, in addition, the first passage is communicated with a cavity of the air box, the first-stage fuel distribution pipe is arranged in the first passage and the cavity of the air box, the second-stage combustor is arranged in the second passage, the top end of the first-stage fuel distribution pipe is provided with a hemispherical sealed surface, the tail end of the first-stage combustor is arranged on the hemispherical sealed surface, and in addition, the inside of the first-stage fuel distribution pipe is communicated with the inside of the first-stage combustor. The multi-spray-nozzle bulky combustion low-NOx gas combustor technically synthesizes fuel grading, smoke gas recirculation and multipoint bulky combustion control techniques, and has the characteristics that long flame in multipoint bulky combustion can be formed, the peak temperature of the combustion flame is reduced, the distribution of heat loads in a furnace is uniform, and the generation amount of NOx is ultralow.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

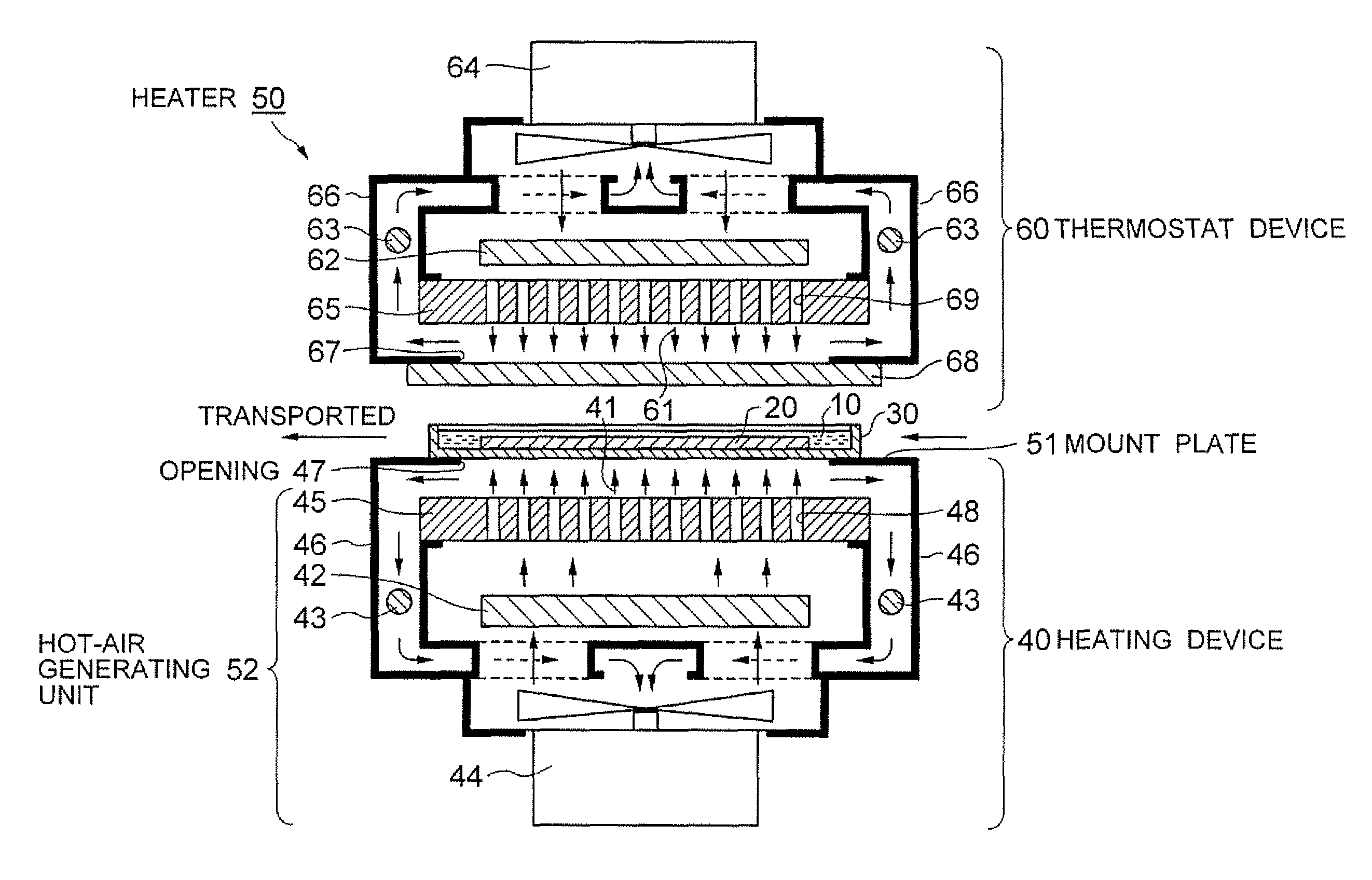

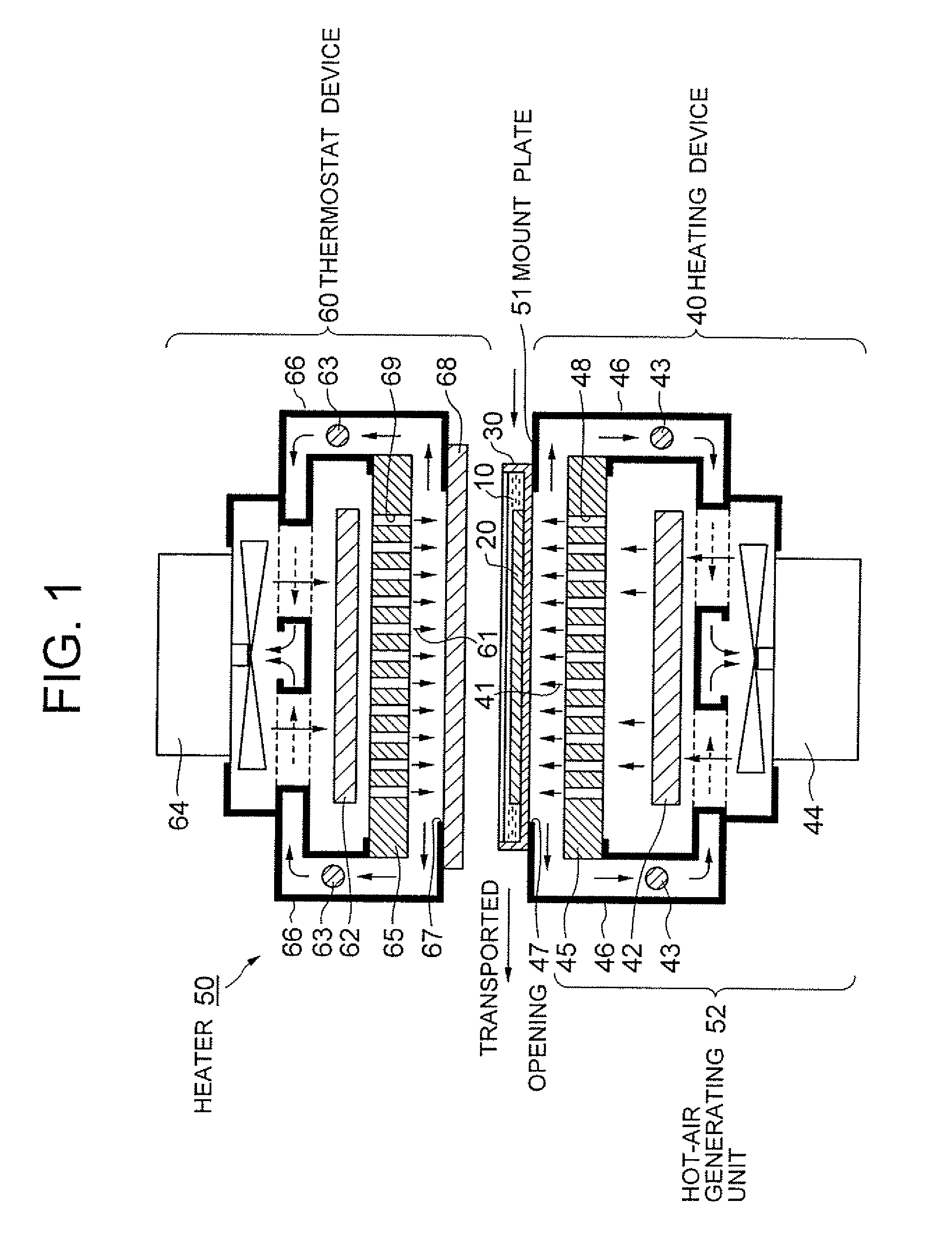

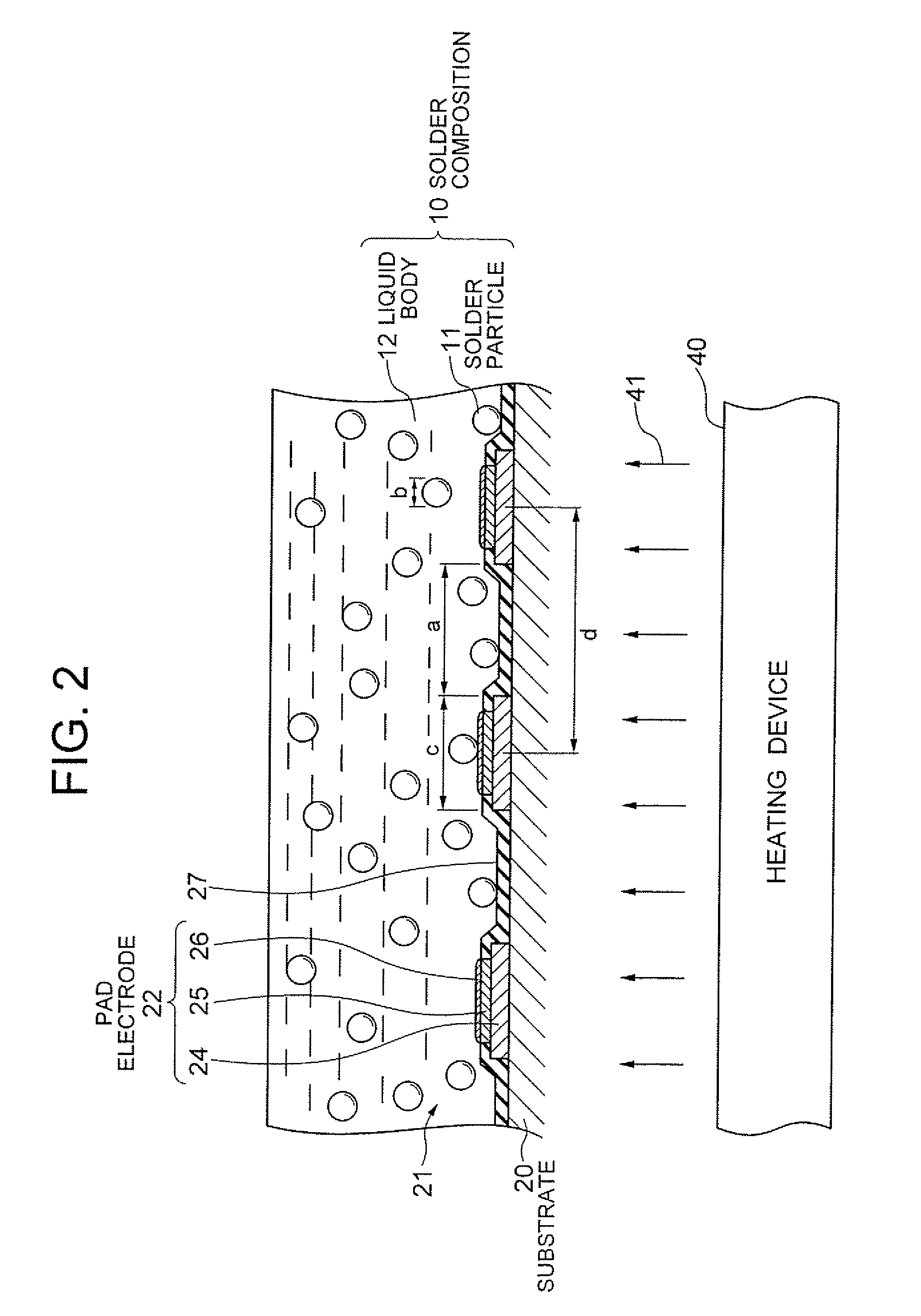

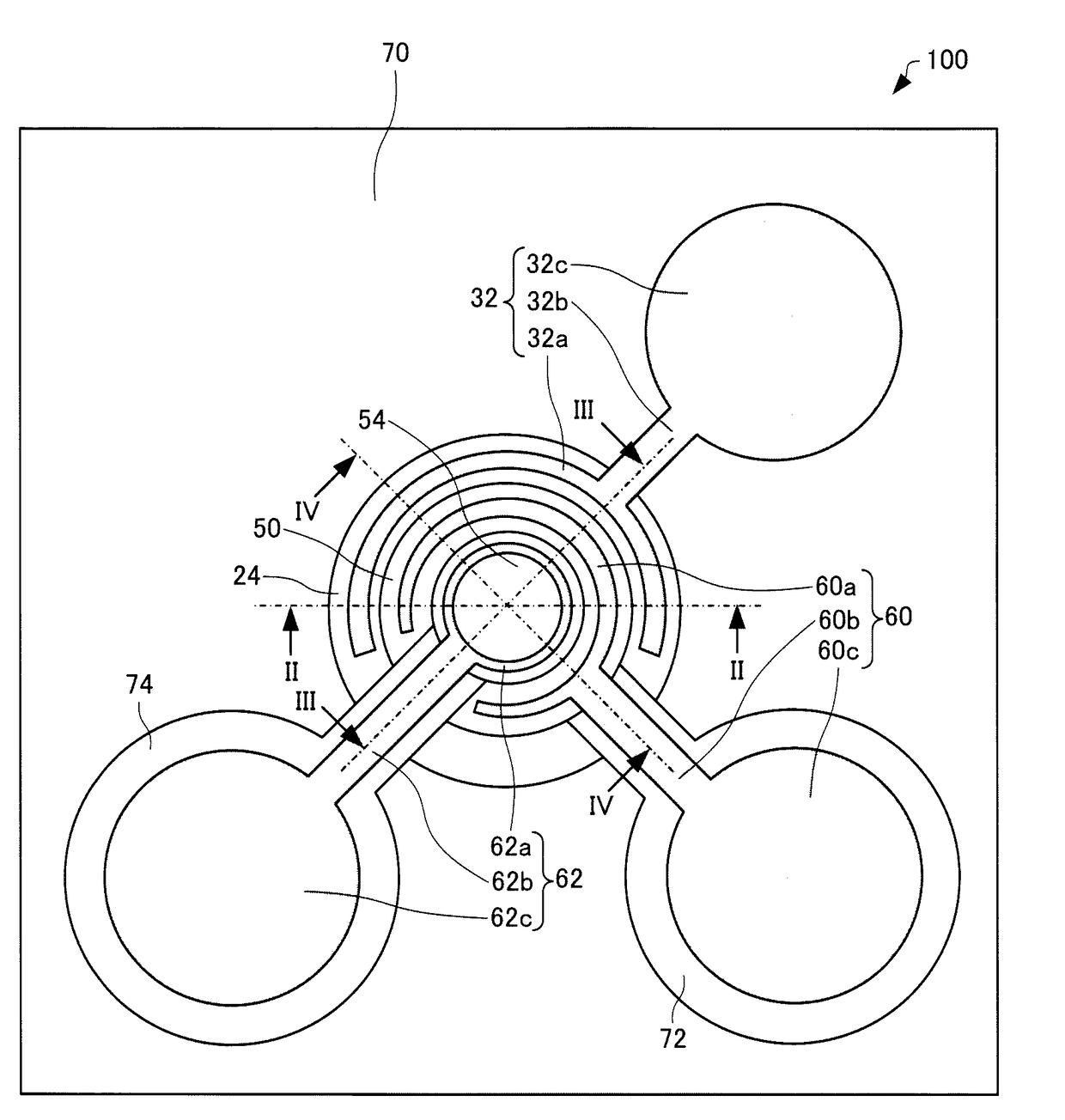

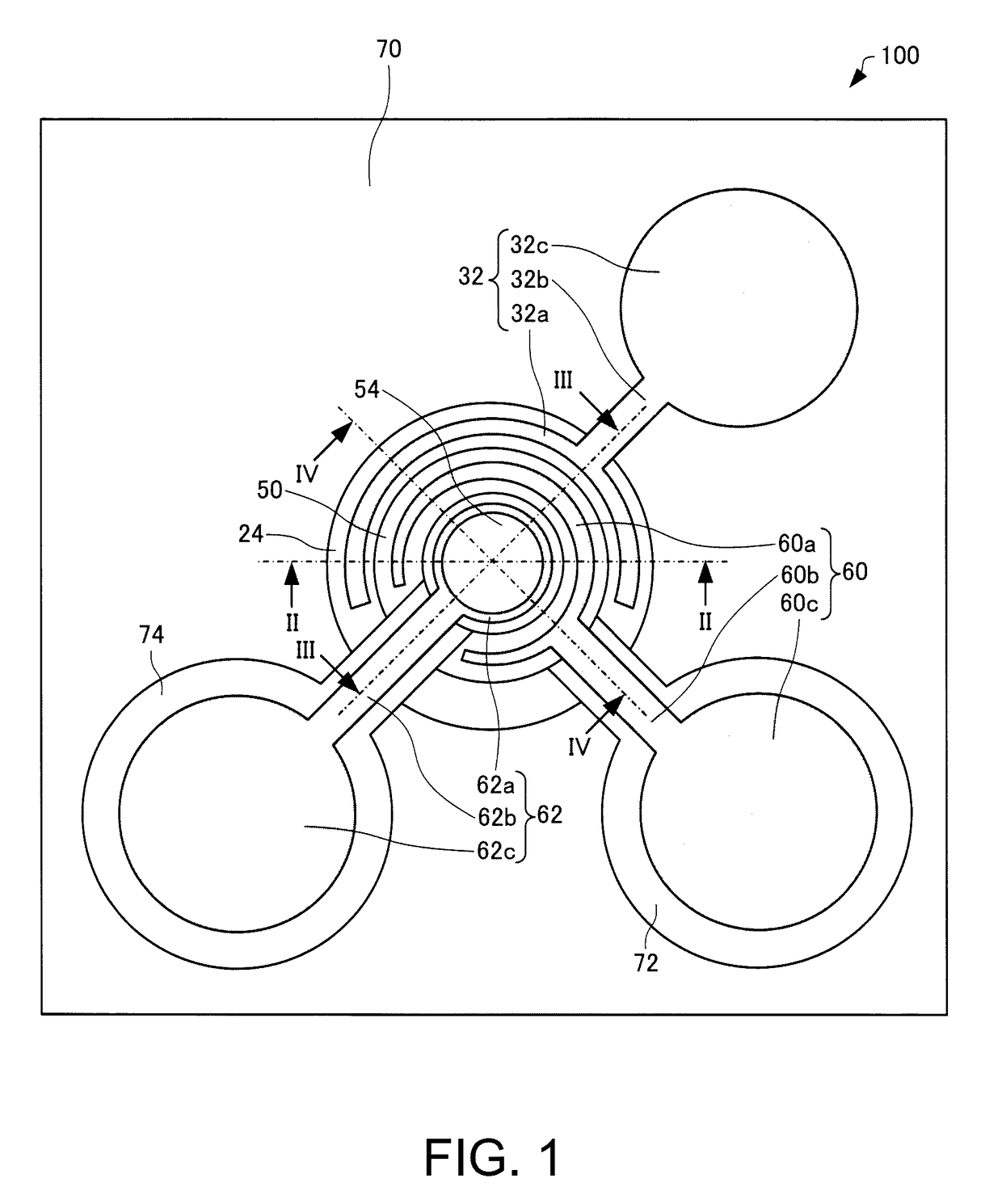

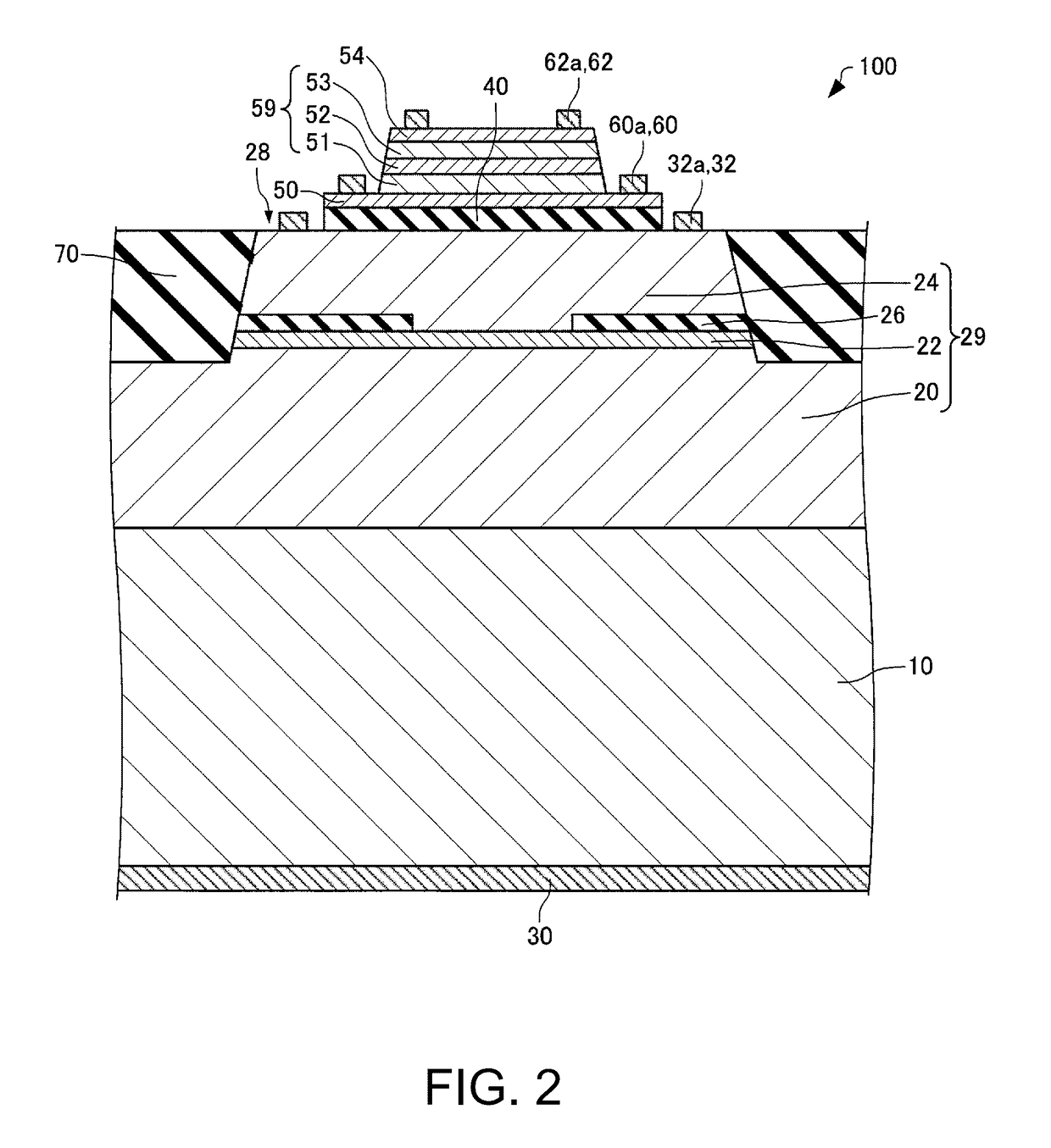

Heater, reflow apparatus, and solder bump forming method and apparatus

InactiveUS8042727B2Reduce riskSuppress generationSemiconductor/solid-state device detailsSolid-state devicesNormal caseMetallurgy

Owner:TAMURA KK +1

Toner for developing electrostatic image, production method thereof, resin particle dispersion, and electrostatic image developer

Provided are a toner for developing an electrostatic image comprising a crystalline resin having an ester bond and at least one of a sulfide bond or a disulfide bond in the main-chain, an electrostatic image developer and an image-forming process by using the same, a method of producing the toner for developing electrostatic image, and a resin particle dispersion using the same.

Owner:FUJIFILM BUSINESS INNOVATION CORP

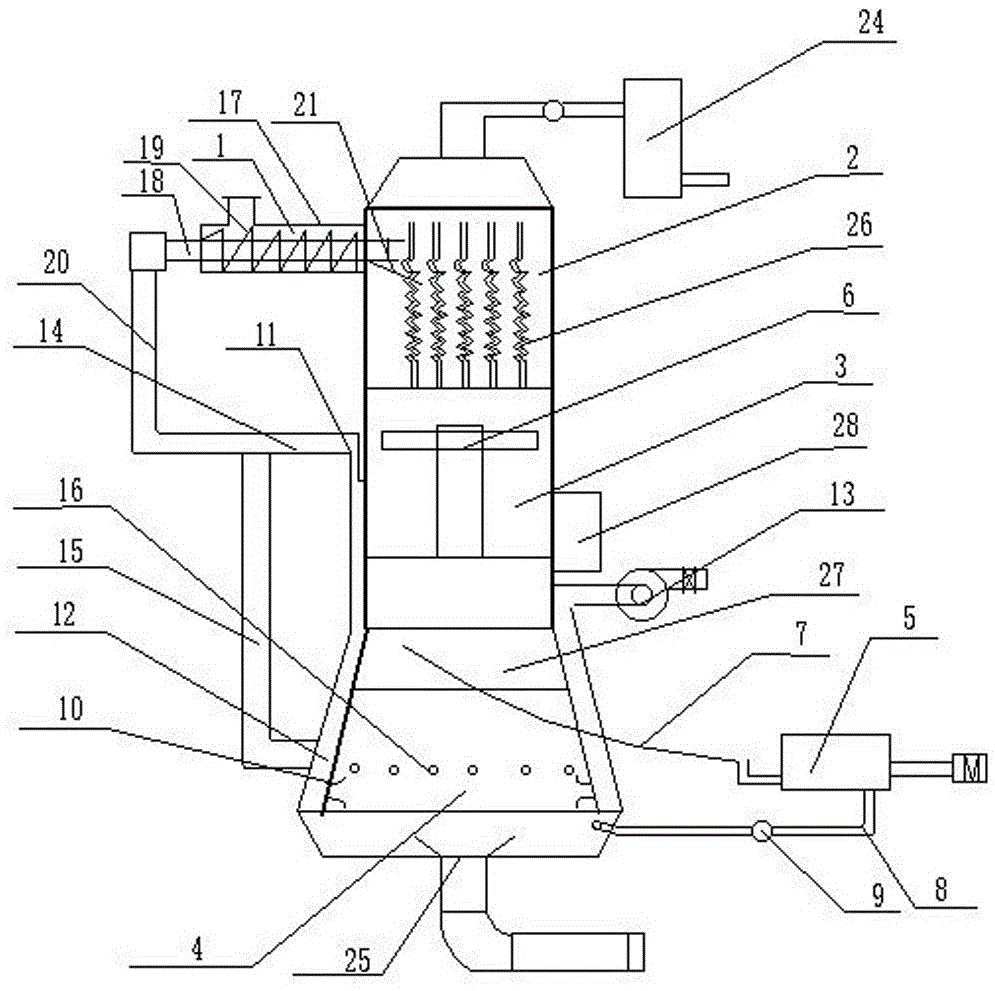

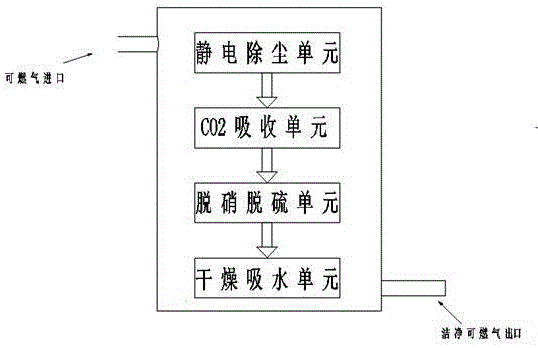

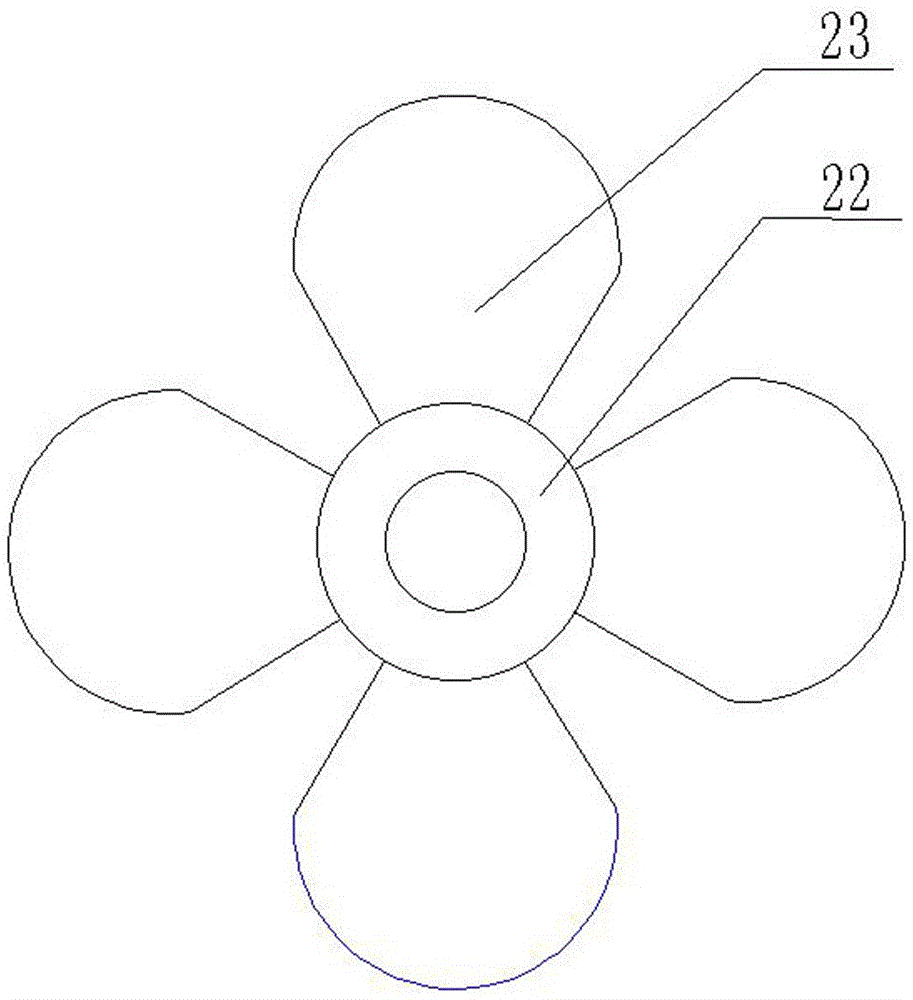

Vertical sludge drying, gasifying and incinerating integrated treatment device and method

ActiveCN106642137ASufficient heat exchangeIncrease profitIncinerator apparatusWaste heat recovery unitCombustion chamber

The invention provides a vertical sludge drying, gasifying and incinerating integrated treatment device and method. The device comprises an electronic control chamber, a feed mechanism, a drying chamber, a gasifying chamber, a combustion chamber for incinerating sludge, a crushing mixer-mill and a waste heat recovery mechanism. The drying chamber, the gasifying chamber and the combustion chamber are sequentially arranged from top to bottom. The waste heat recovery system can recover and use heat of the combustion chamber and the gasifying chamber, sludge gasified by the gasifying chamber and a small amount of pulverized coal are mixed and milled in the crushing mixer-mill and then enter the combustion chamber to be incinerated, and gas generated after gasifying is completed is exhausted through a combustible gas channel formed in the drying chamber. The vertical sludge drying, gasifying and incinerating integrated treatment device and method have the advantages of being integrated, compact in structure, environmentally friendly, high in gasifying efficiency and wide in application range, saving energy and the like, and is suitable for treatment of common domestic sludge and chemical engineering polluted sludge and similarly suitable for treatment of urban solid waste, and therefore the problems of energy shortage and environmental pollution control are effectively relieved.

Owner:HENAN UNIV OF SCI & TECH

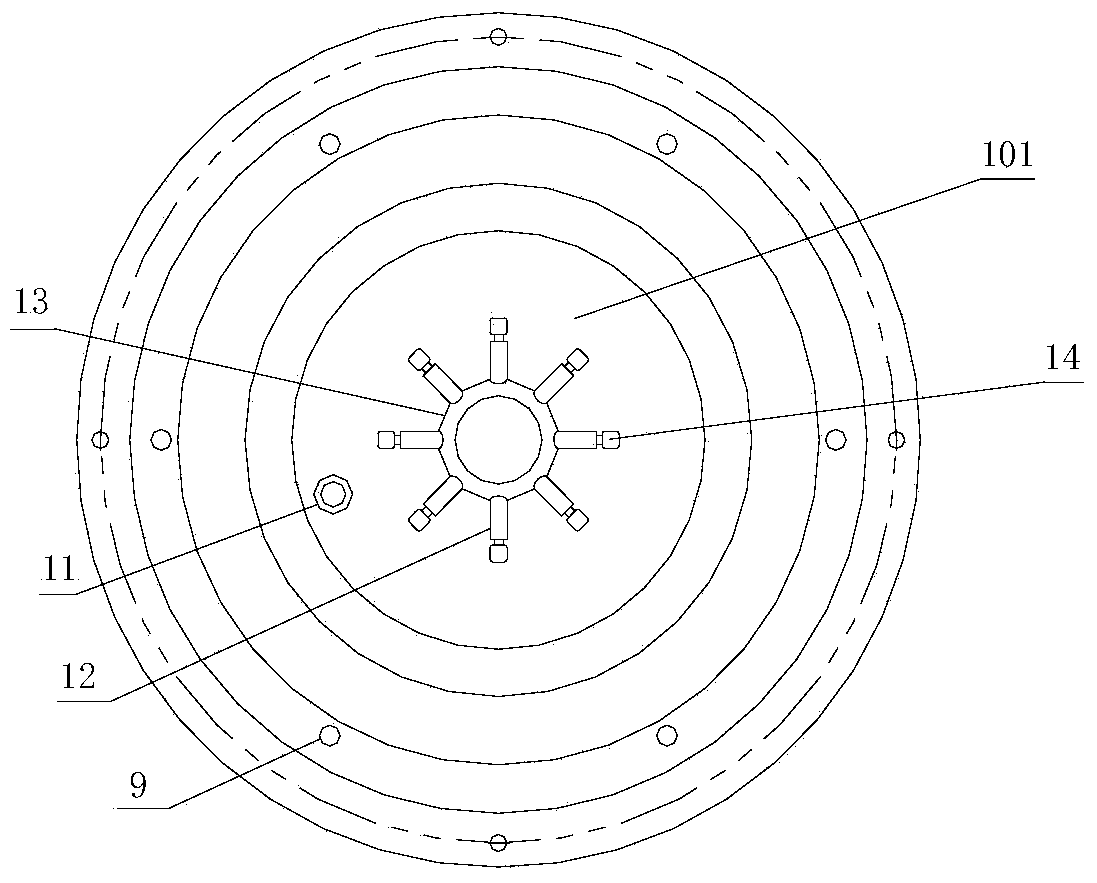

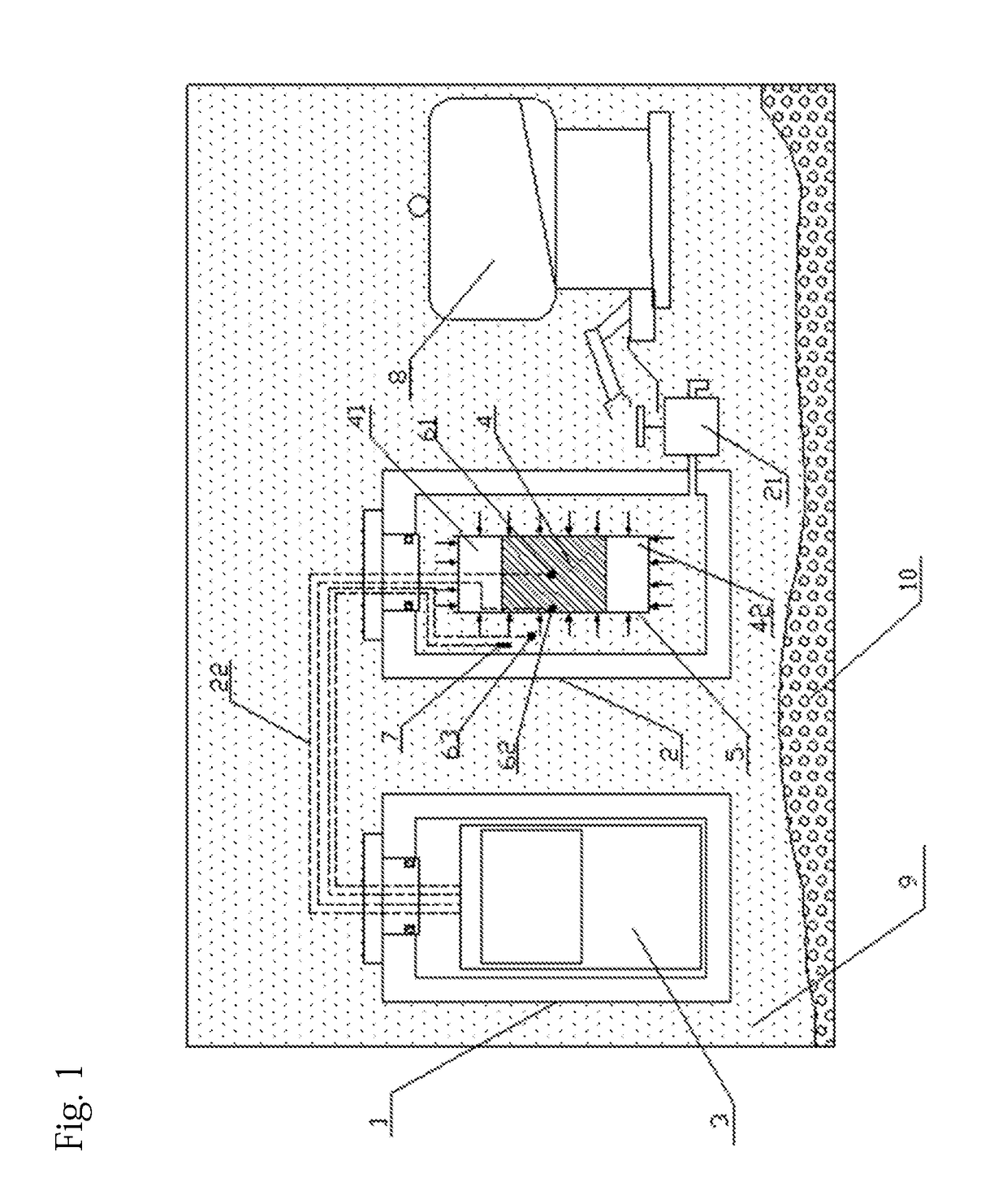

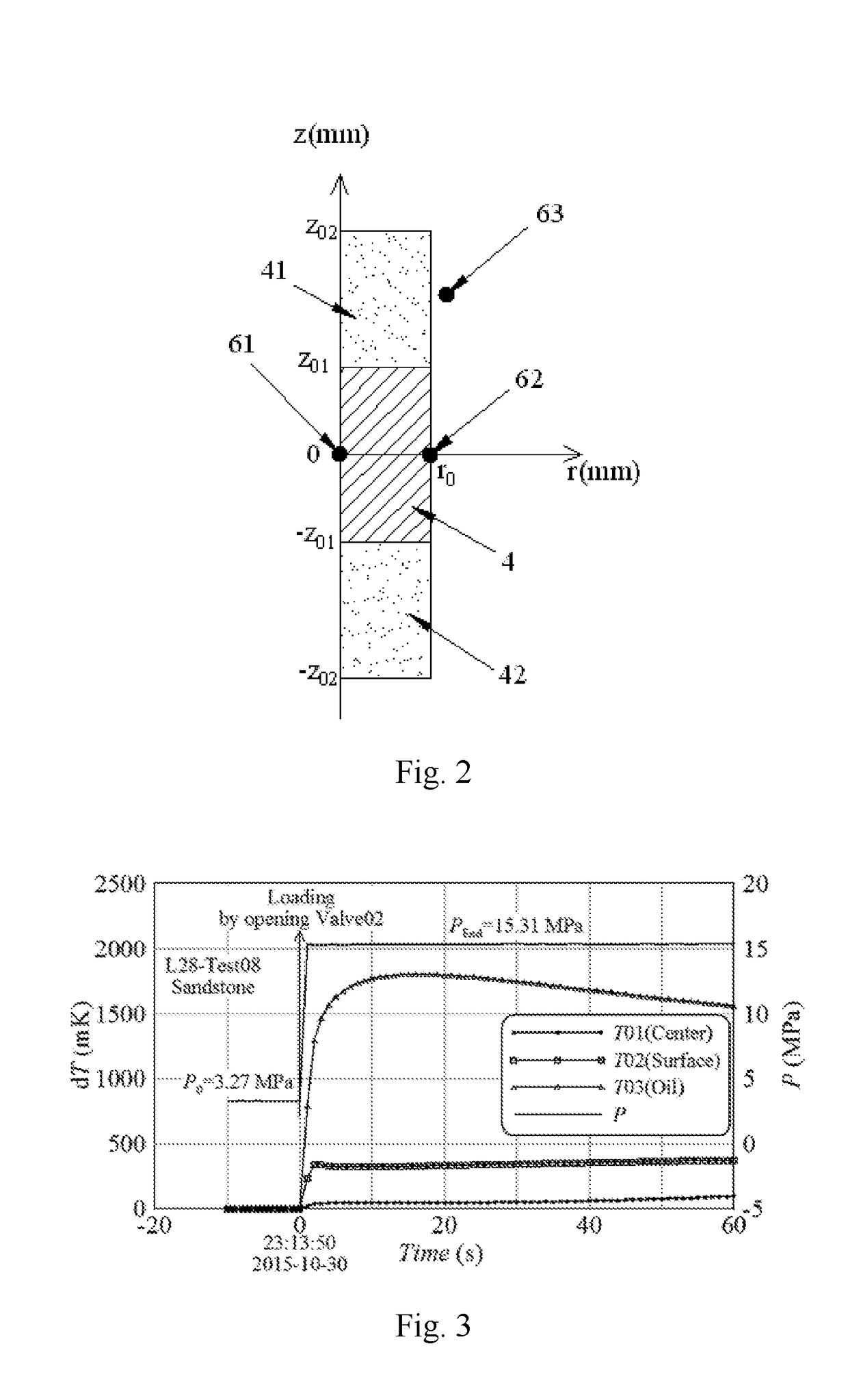

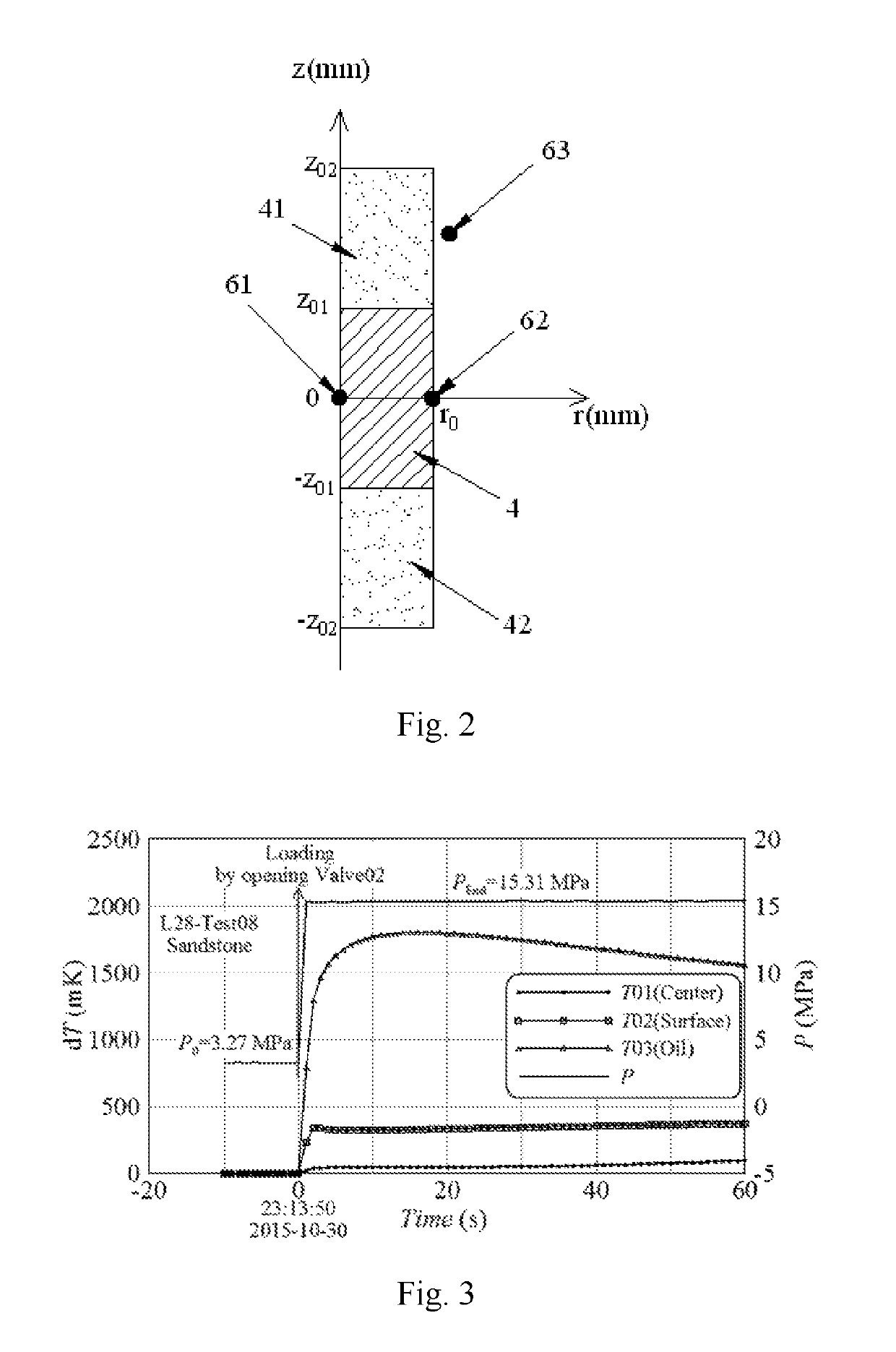

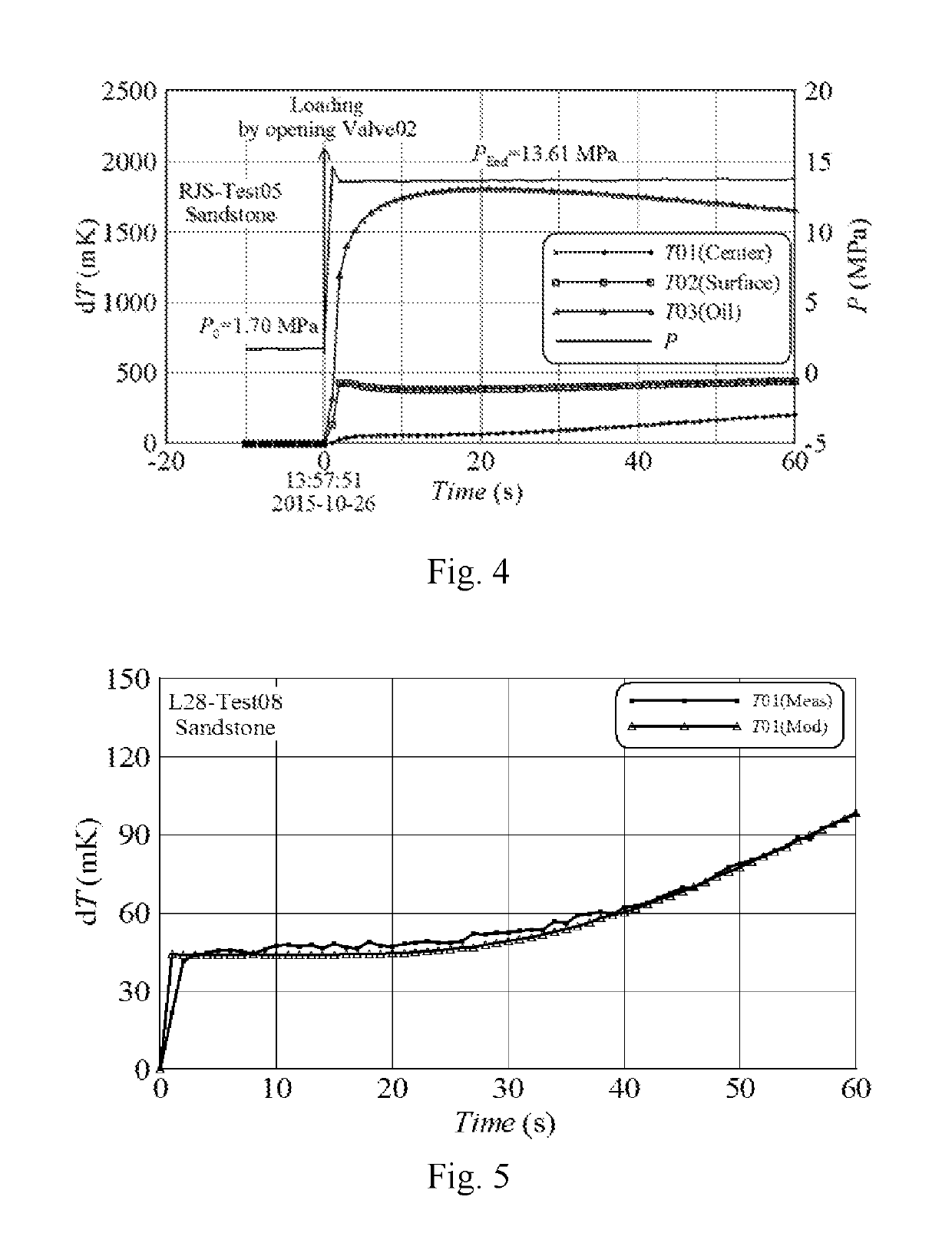

System and method for determining the thermal properties of rocks under high pressure conditions in deep sea

ActiveUS20180113087A1Easy to operateHeating sourceMaterial heat developmentMaterial strength using tensile/compressive forcesEngineeringHigh pressure

A system for determining the thermal properties of rocks under high pressure conditions in deep sea includes a first pressure vessel having a data collecting unit and a second pressure vessel having a chamber being filled with seawater, communicating with a drain valve, and having a rock sample disposed therein. First and second temperature sensors are respectively disposed in the center and on the surface of the rock sample. A third temperature sensor and a pressure sensor are disposed in the chamber. Outputs of the temperature sensors and the pressure sensor are communicated with inputs of the data collecting unit via watertight cables. Determining the thermal properties of rocks under high pressure conditions in deep sea includes rapidly opening the drain valve for instant loading of the rock sample and introducing an established finite element numerical inversion model. No heat source for electrical heating nor booster pump is needed.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

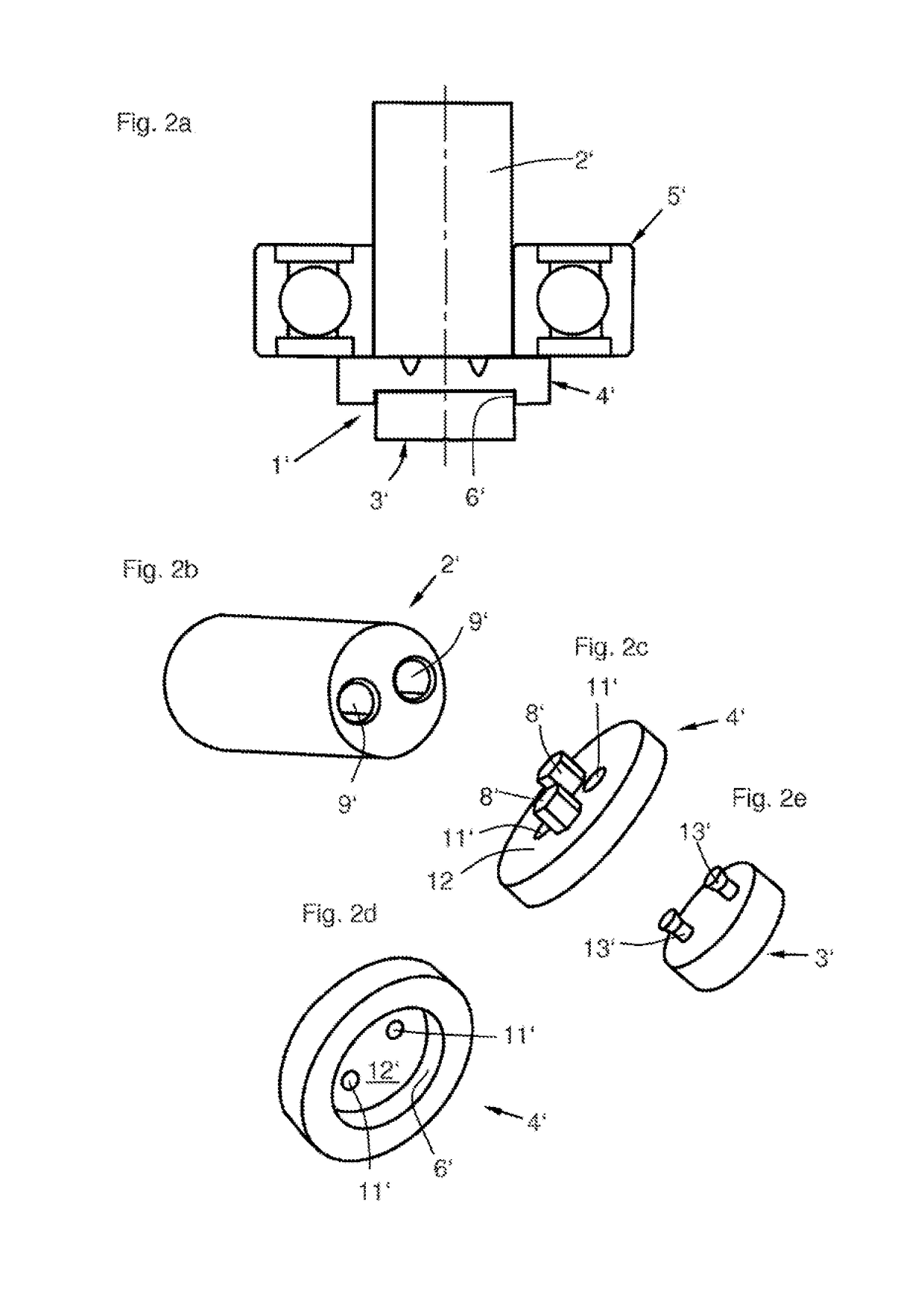

Magnet sensor assembly

InactiveUS20180031628A1Easily pre-assembledReduce necessityElectronic circuit testingInorganic material magnetismRolling-element bearingElectric drive

A magnet sensor assembly for use in an electric drive having a shaft with a shaft end. The magnet sensor assembly includes a magnet sensor having a permanent magnet bonded in plastic, an adapter, means for mounting the magnet sensor on the shaft end of the shaft, means for connecting the adapter to the magnet sensor and a force-fit connection for mounting the adapter on the shaft end. The invention provides a magnet sensor assembly which allows as simple a connection as possible to be established between a magnet sensor and a shaft end of a shaft or an inner ring of a rolling element bearing secured to the shaft, for which simple manufacturing and mounting methods may be used which are reliable.

Owner:BUHLER MOTOR GMBH

Sun filter for spacecraft

ActiveUS20180128951A1Reduce temperature gradientReduce and to eliminate unwanted lossCosmonautic environmental control arrangementOptical filtersClassical mechanicsWavelength

A device for a sending and receiving unit of a communication arrangement is provided. The device includes: a first passage for electromagnetic waves and a second passage for electromagnetic waves; a partially transparent surface which is transparent for electromagnetic waves of a first wave length range and which is reflective for electromagnetic waves of a second wave length range, wherein the second wave length range differs from the first wave length range; and a first retroreflective surface which is retroreflective for electromagnetic waves of the first wave length range. A direction of reflection of the electromagnetic waves of the first wave length range differs from a direction of reflection of the electromagnetic waves of the second wave length range if the electromagnetic waves of the first wave length range as well as the electromagnetic waves of the second wave length range are incoming through the same passage.

Owner:TESAT SPACECOM

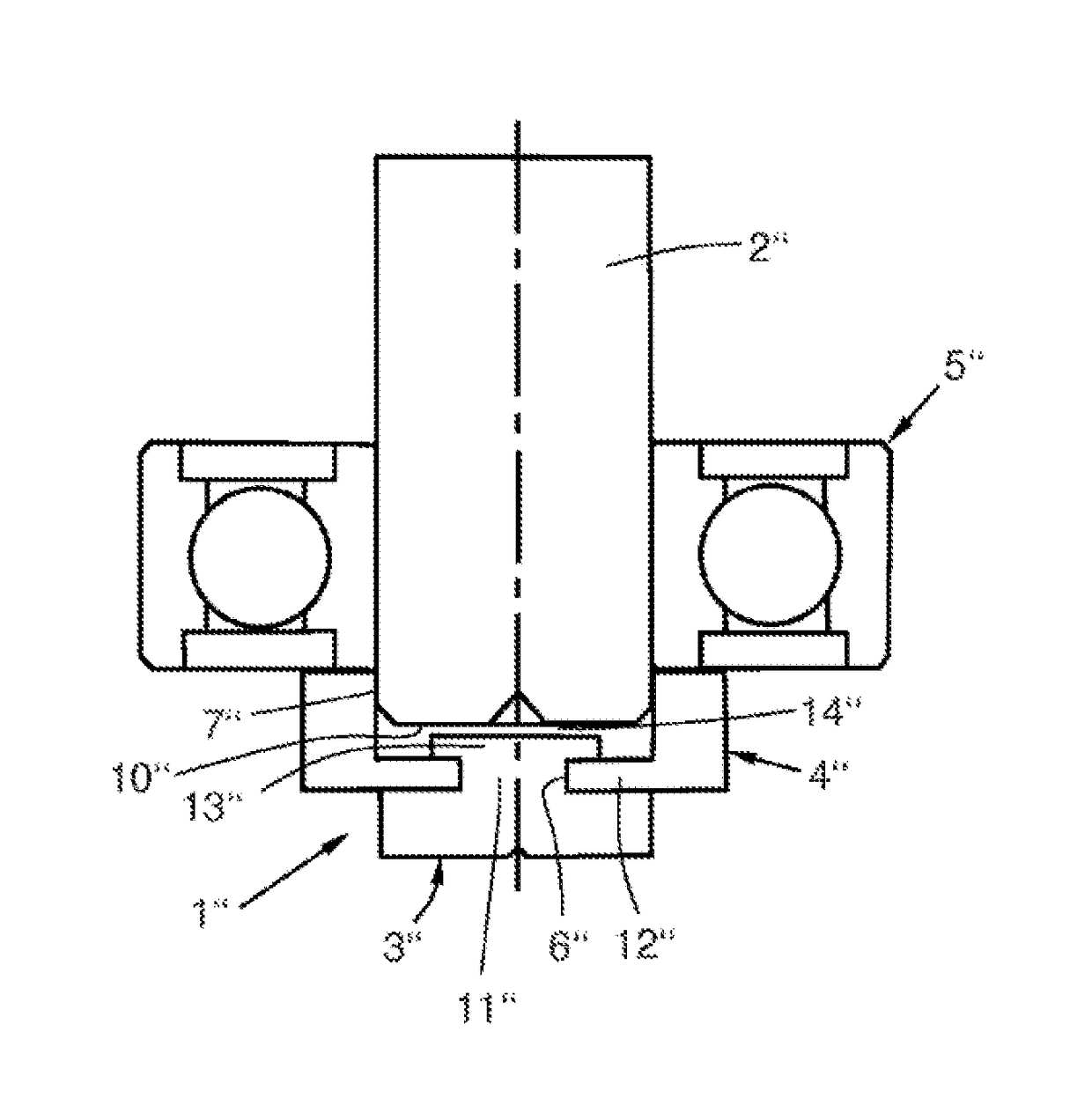

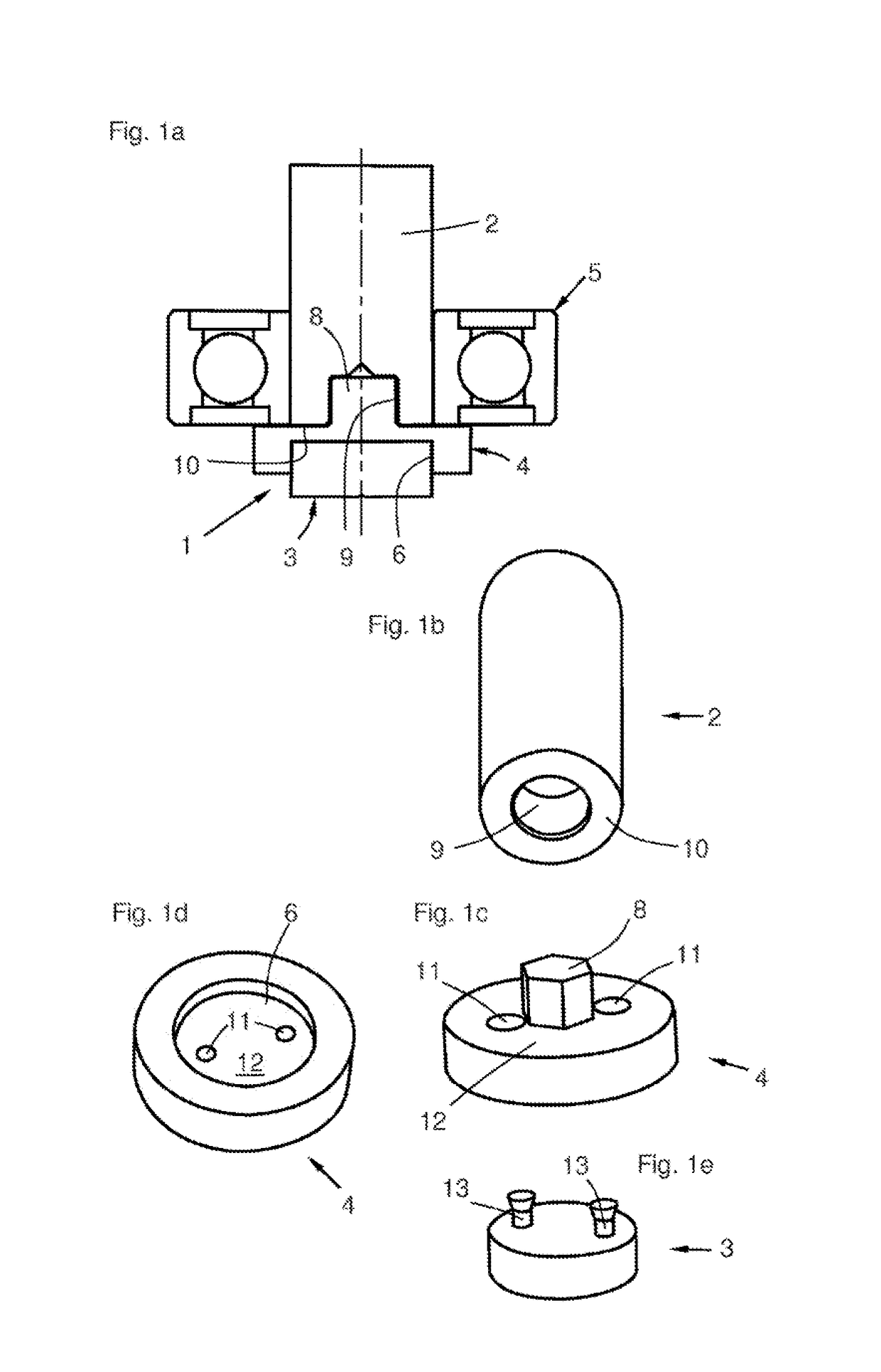

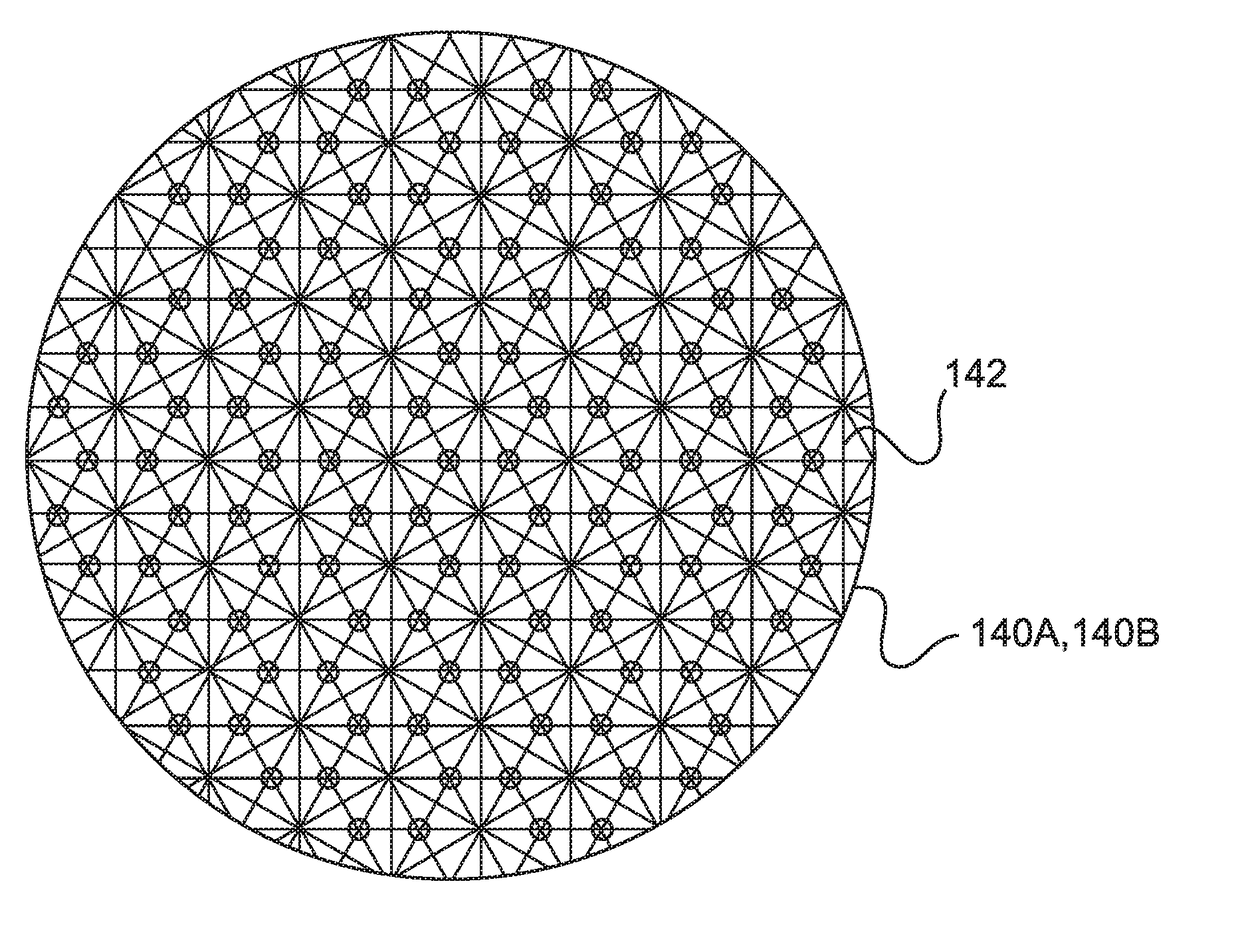

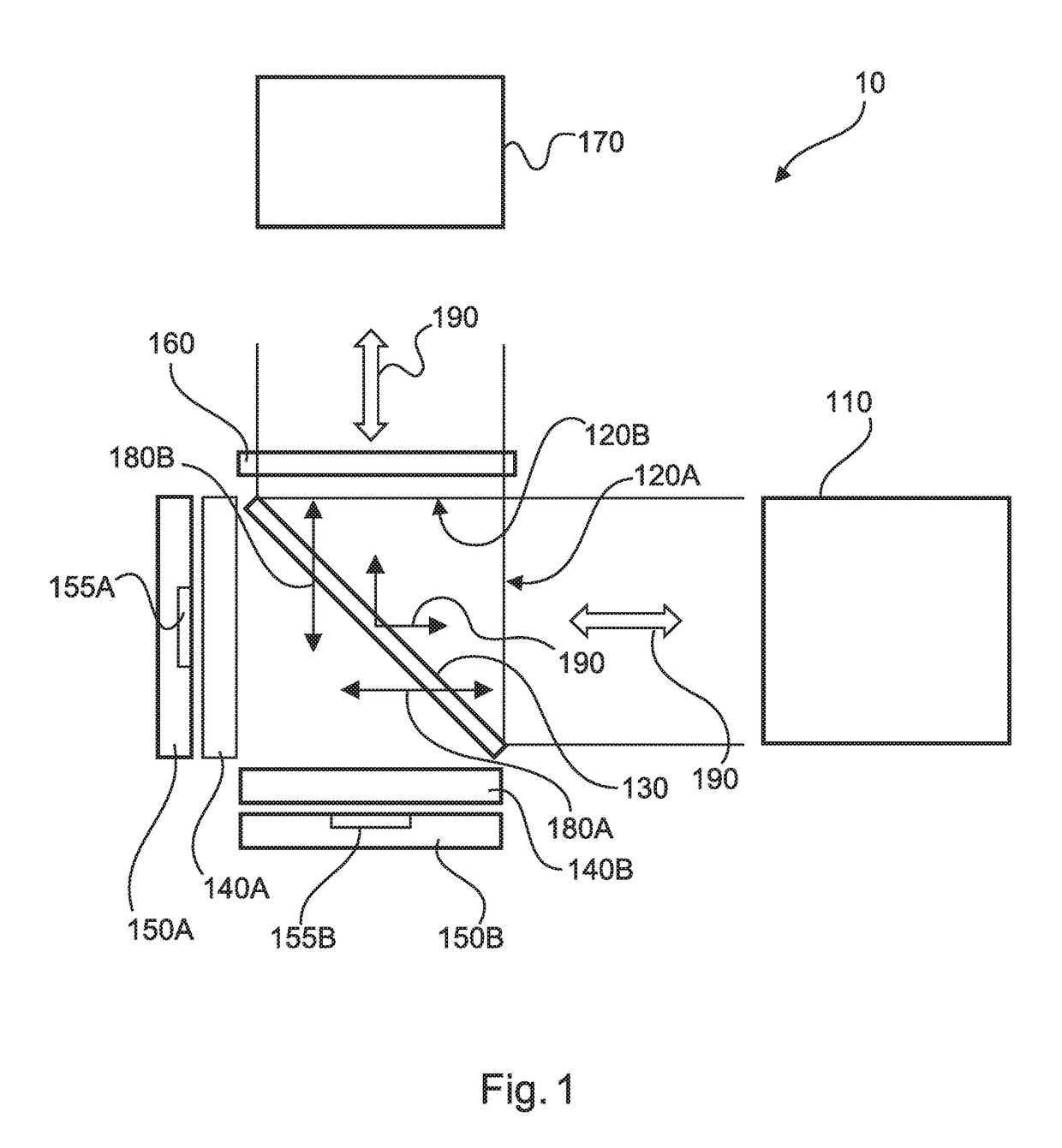

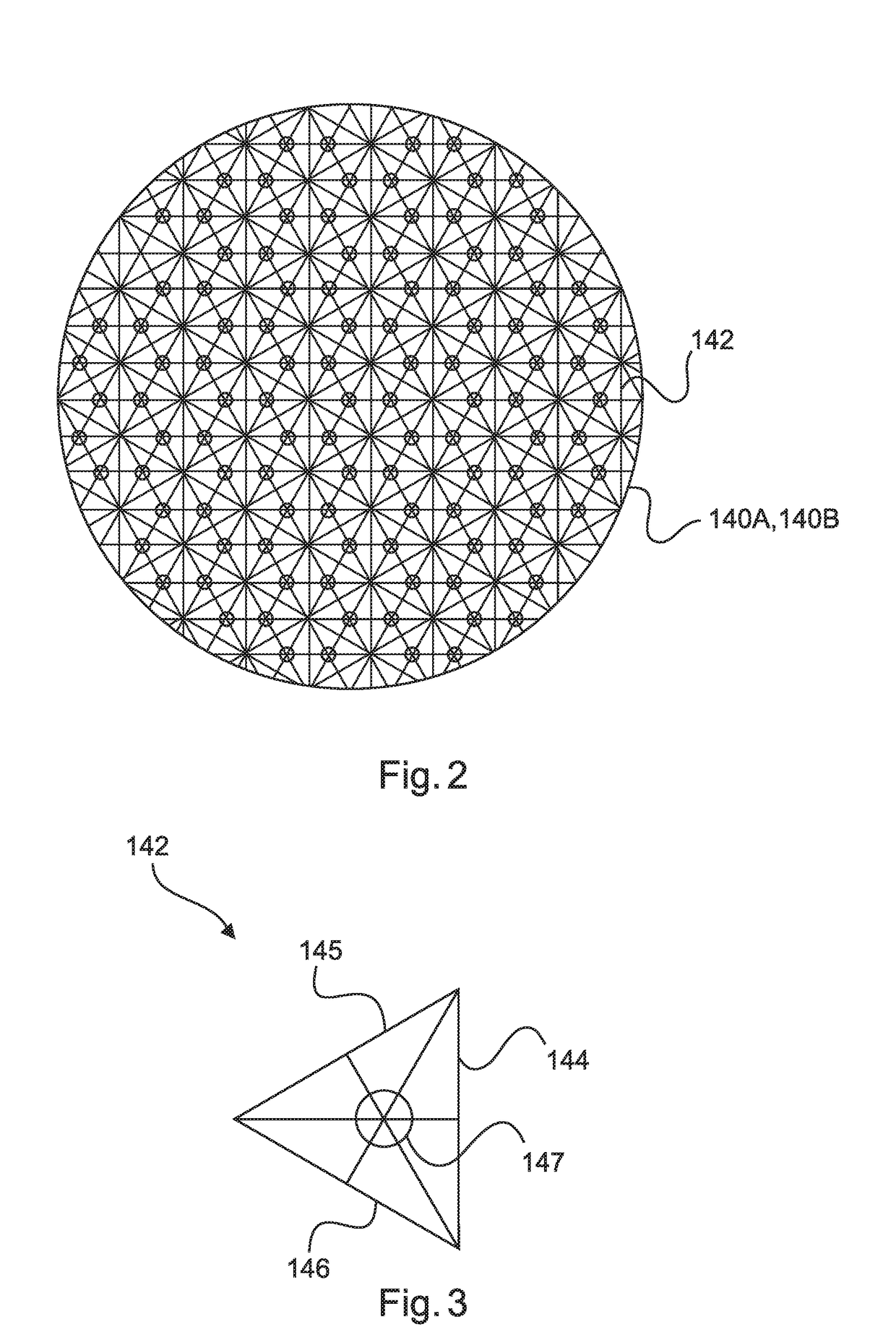

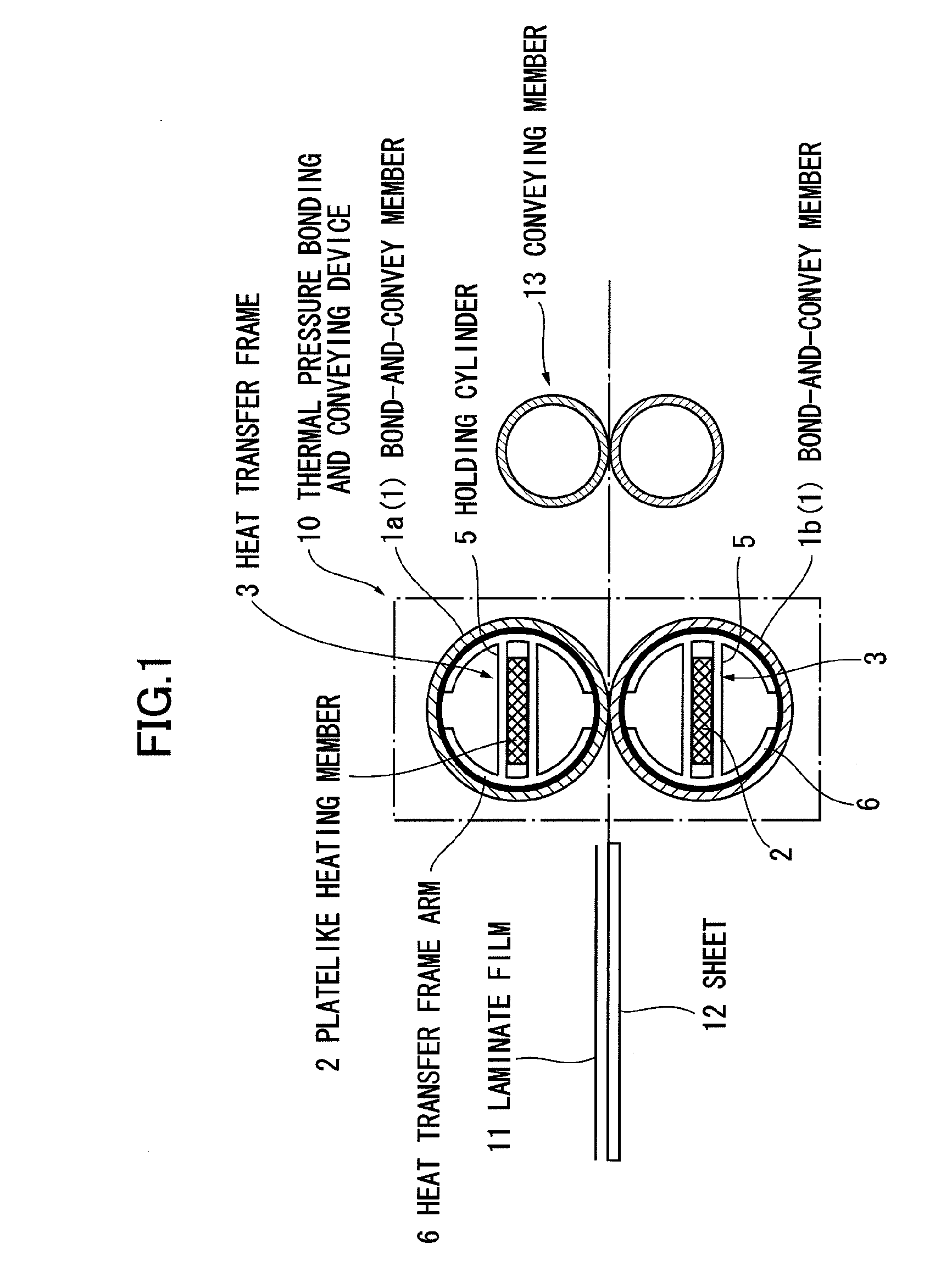

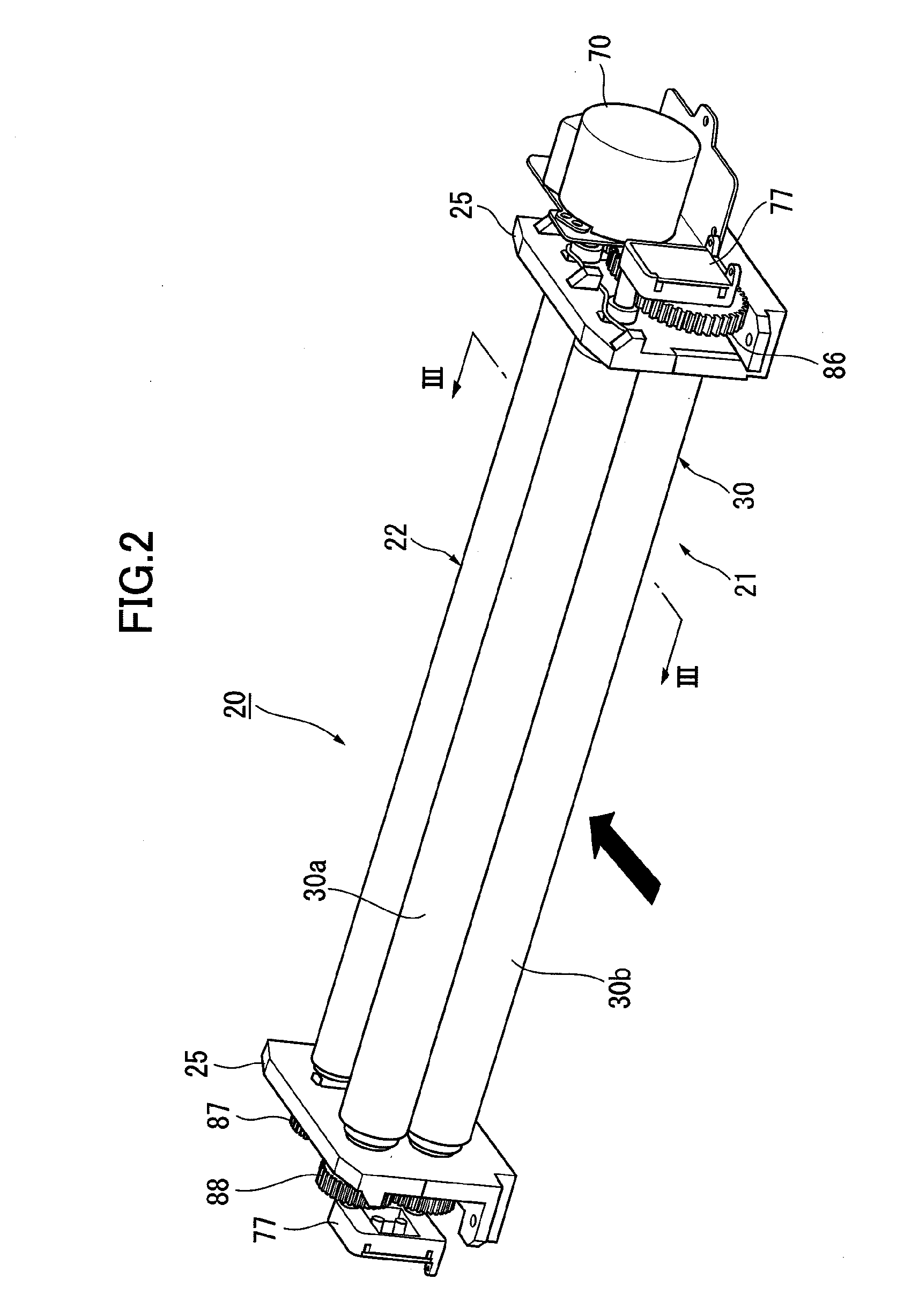

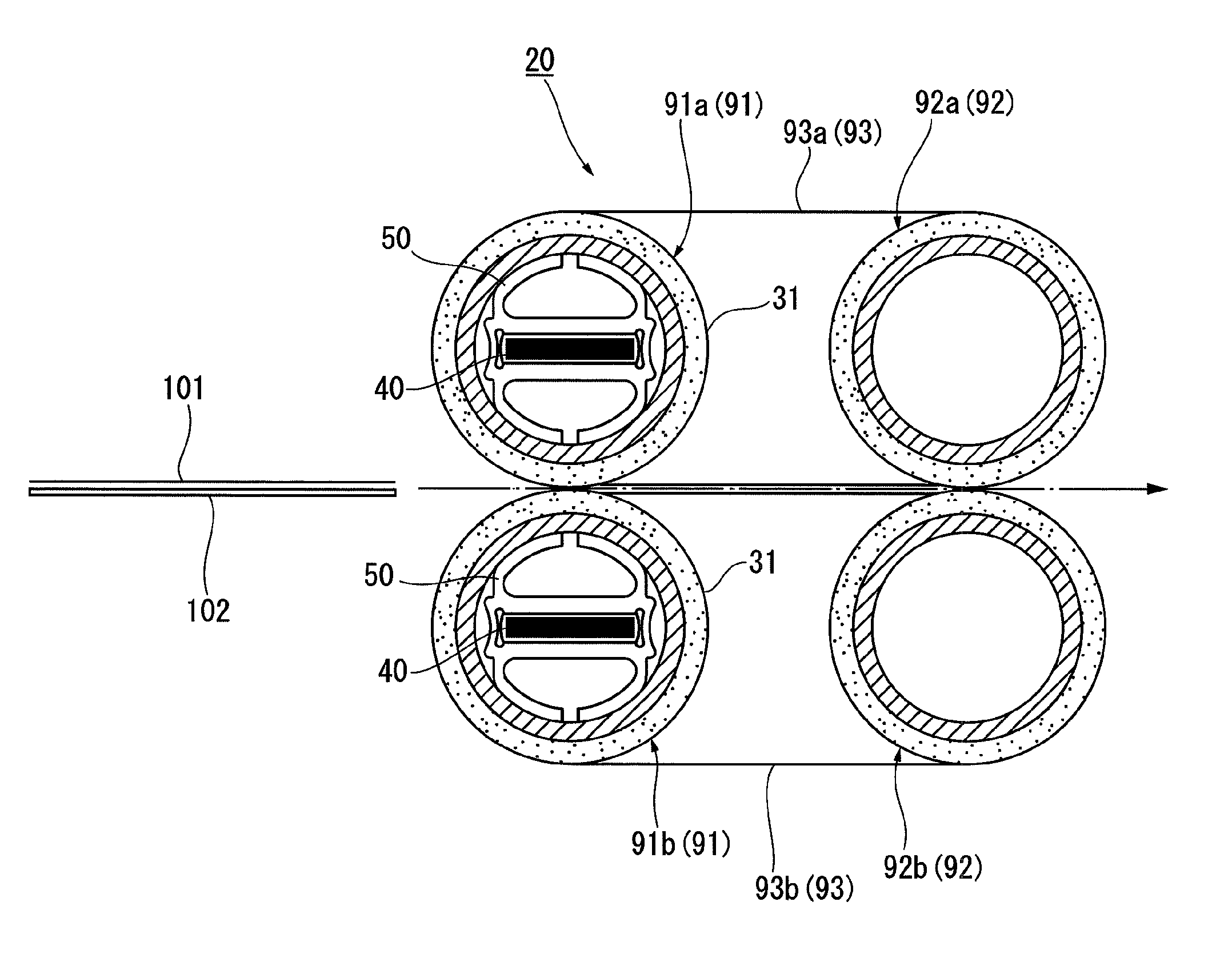

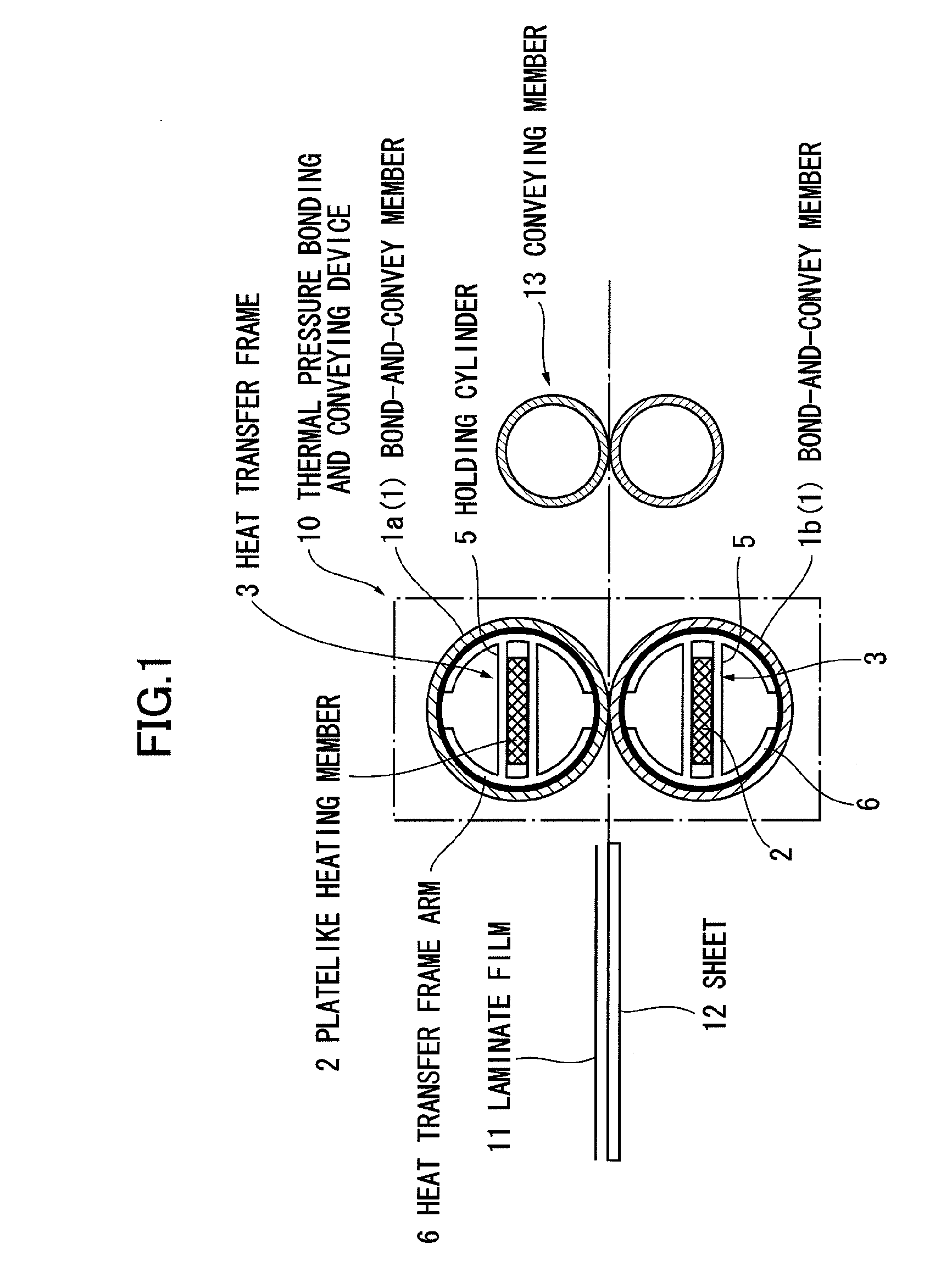

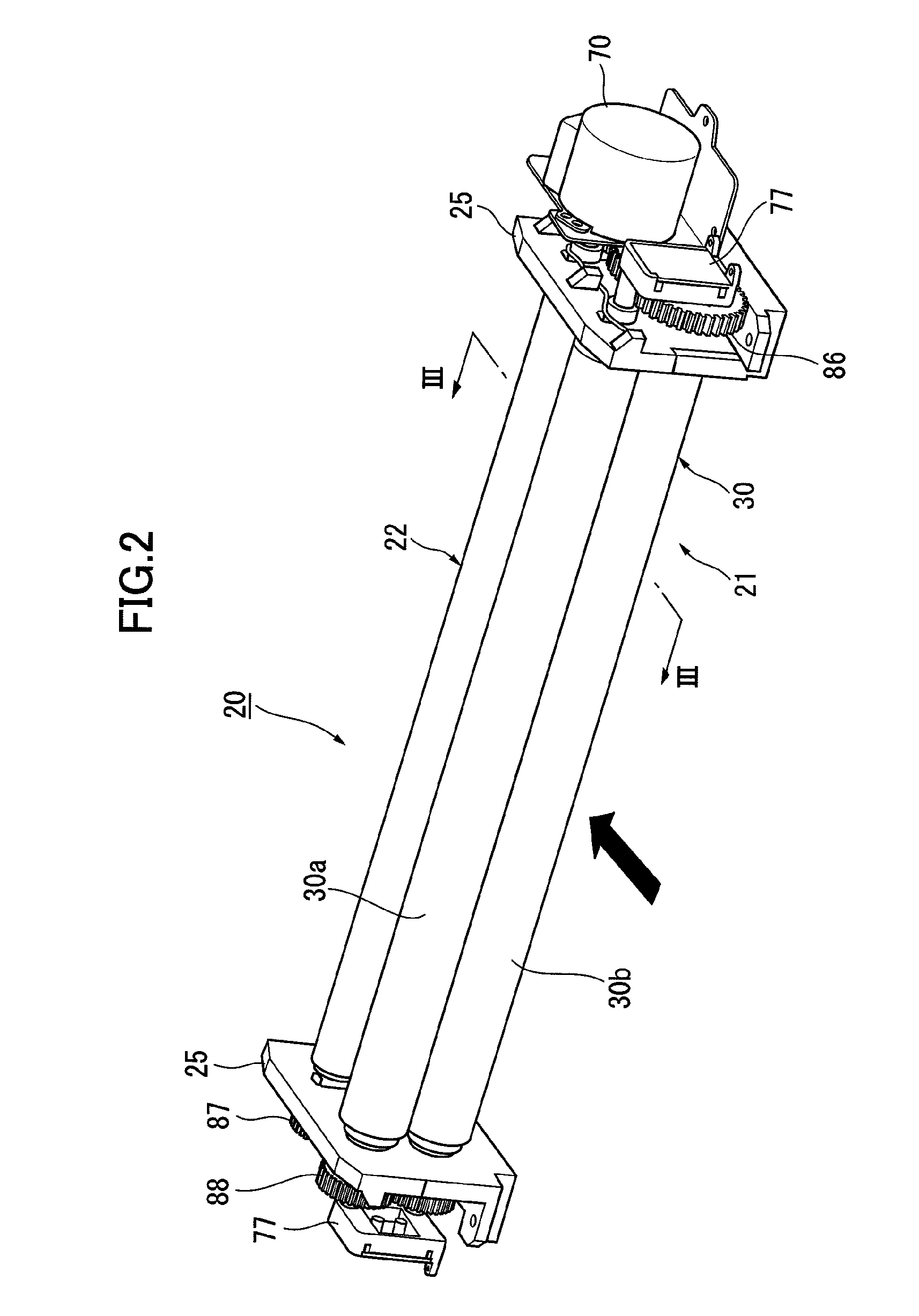

Laminating device and thermal pressure bonding and conveying device used in laminating device

InactiveUS20120048470A1Rate of riseLaminating temperature can be stableControlling laminationLaminationTemperature controlControl system

A laminating device is provided that can increase the rate of rise of a laminating temperature and keep the laminating temperature stable without using a temperature control system for a heat source. The laminating device for stacking and bonding a laminate film 11 coated with a hot-melt adhesive and a sheet 12 has a thermal pressure bonding and conveying device 10 that thermally pressure-bonds the laminate film 11 and the sheet 12 while stacking and conveying them. The thermal pressure bonding and conveying device 10 comprises: a pair of bond-and-convey members 1, at least one of them formed as a hollow roll, to grip and convey the laminate film 11 and the sheet 12; a platelike heating member 2 having a platelike PTC thermistor and placed in at least one of the paired bond-and-convey members which is formed as a hollow roll; and a heat transfer frame 3 placed inside and in contact with the hollow roll-shaped bond-and-convey member 1, holding the platelike heating member 2 therein and being able to transfer heat from the platelike heating member 2 to the hollow roll-shaped bond-and-convey member 1.

Owner:SAKAE CO LTD

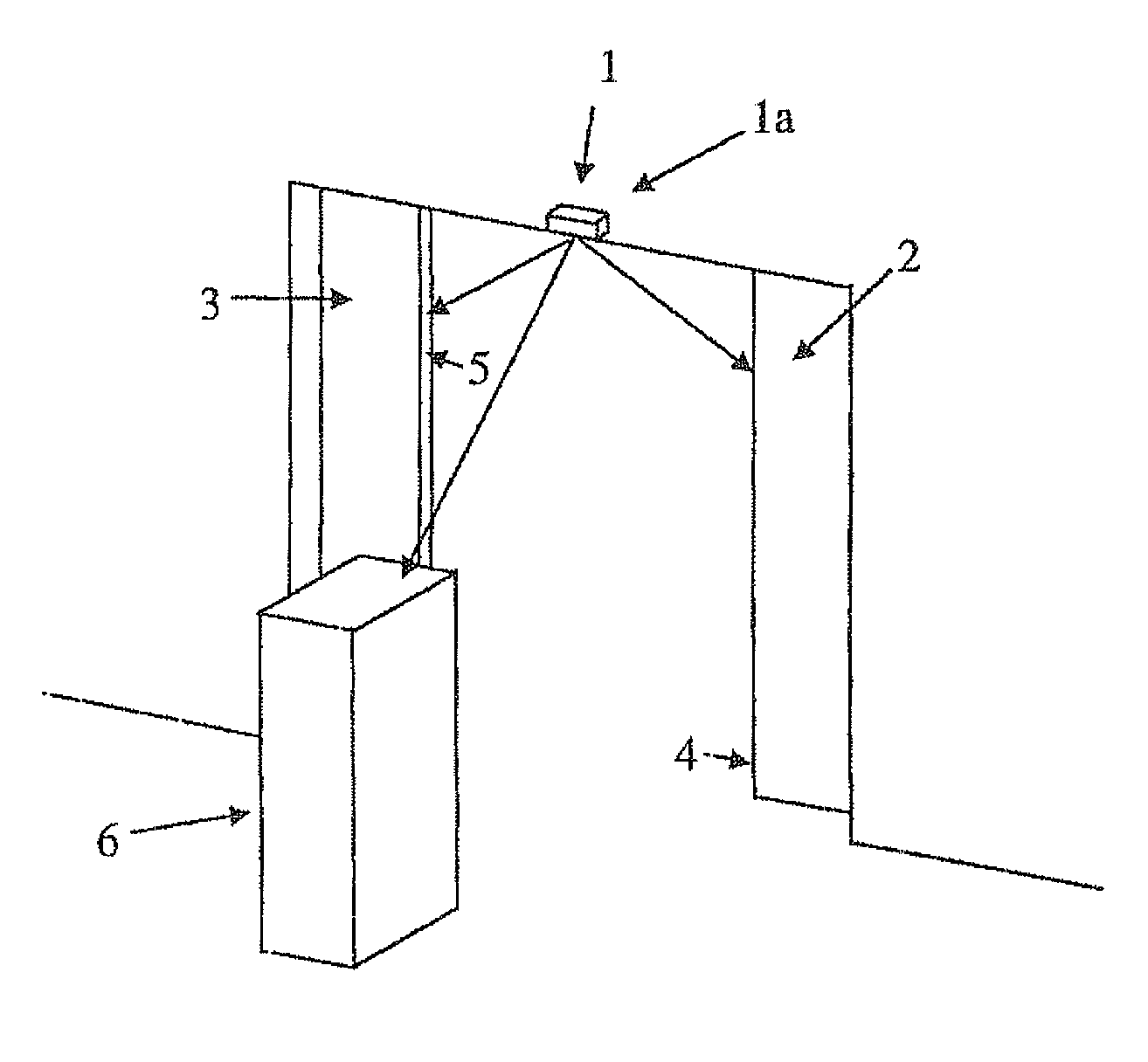

Sensor device

ActiveUS20080225263A1Avoid temperatureAvoid temperature effectsOptical rangefindersPower-operated mechanismPropagation timeElectromagnetic radiation

A sensor device including a source for electromagnetic radiation, a receiver and a control device, the control device being designed for emitting electromagnetic radiation by means of the source and for determining a distance that is covered by the electromagnetic radiation emitted by the source from a reflection surface of an object to the receiver, doing so by evaluating a propagation time of the radiation or a phase of an oscillation modulated onto the radiation. According to the invention, the control device provides an economy mode in which the power of the source is lower in a prescribed time interval by comparison with a normal object detection mode, means being provided to ensure switching back into the normal object detection mode in the event of a predefined object situation.

Owner:CEDES AG

Laminating device and thermal pressure bonding and conveying device used in laminating device

InactiveUS8517080B2Temperature fluctuationTemperature is prevented exceeding set temperatureMechanical working/deformationLaminationTemperature controlControl system

A laminating device is provided that can increase the rate of rise of a laminating temperature and keep the laminating temperature stable without using a temperature control system for a heat source. The laminating device for stacking and bonding a laminate film 11 coated with a hot-melt adhesive and a sheet 12 has a thermal pressure bonding and conveying device 10 that thermally pressure-bonds the laminate film 11 and the sheet 12 while stacking and conveying them. The thermal pressure bonding and conveying device 10 comprises: a pair of bond-and-convey members 1, at least one of them formed as a hollow roll, to grip and convey the laminate film 11 and the sheet 12; a platelike heating member 2 having a platelike PTC thermistor and placed in at least one of the paired bond-and-convey members which is formed as a hollow roll; and a heat transfer frame 3 placed inside and in contact with the hollow roll-shaped bond-and-convey member 1, holding the platelike heating member 2 therein and being able to transfer heat from the platelike heating member 2 to the hollow roll-shaped bond-and-convey member 1.

Owner:SAKAE CO LTD

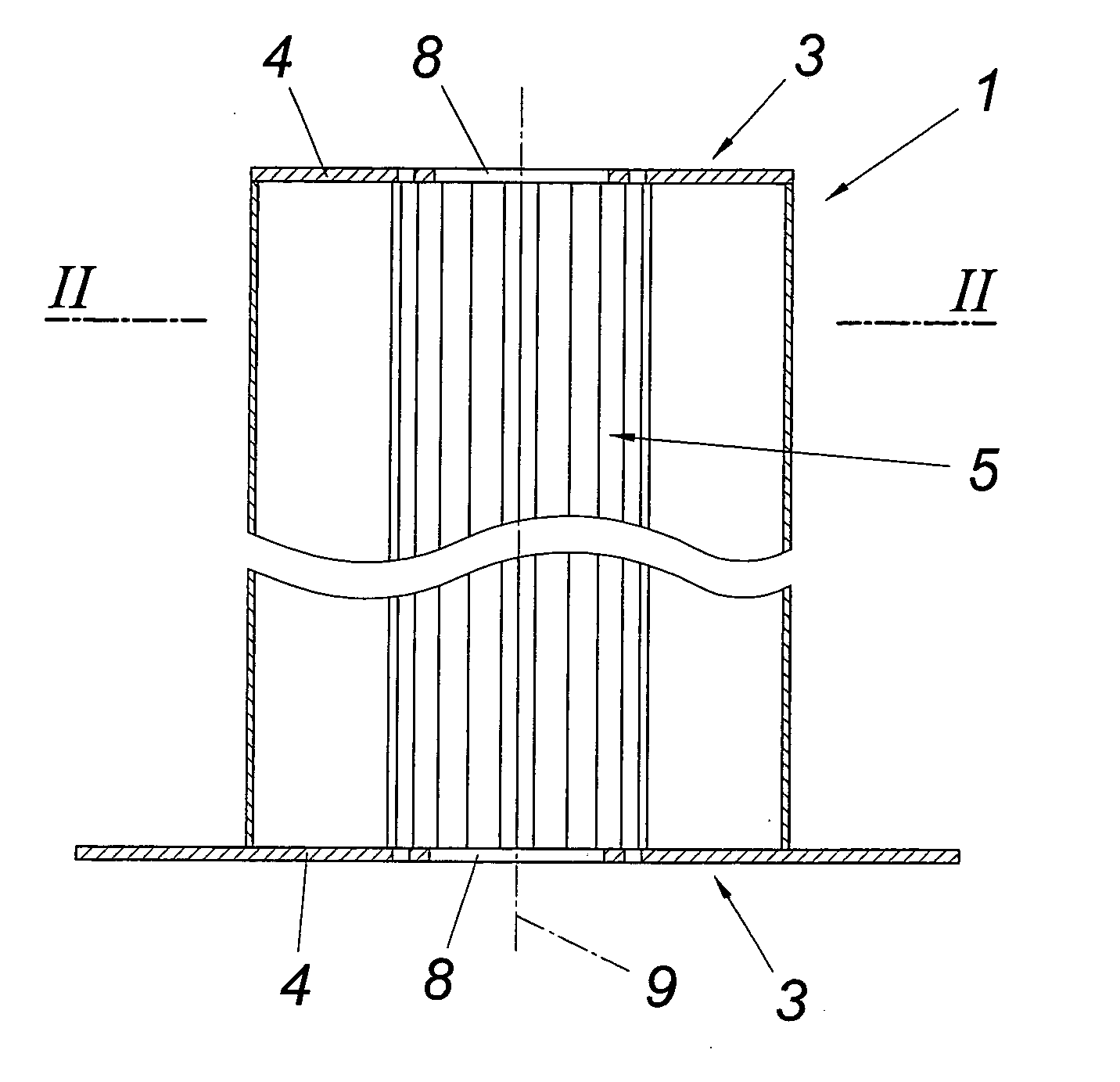

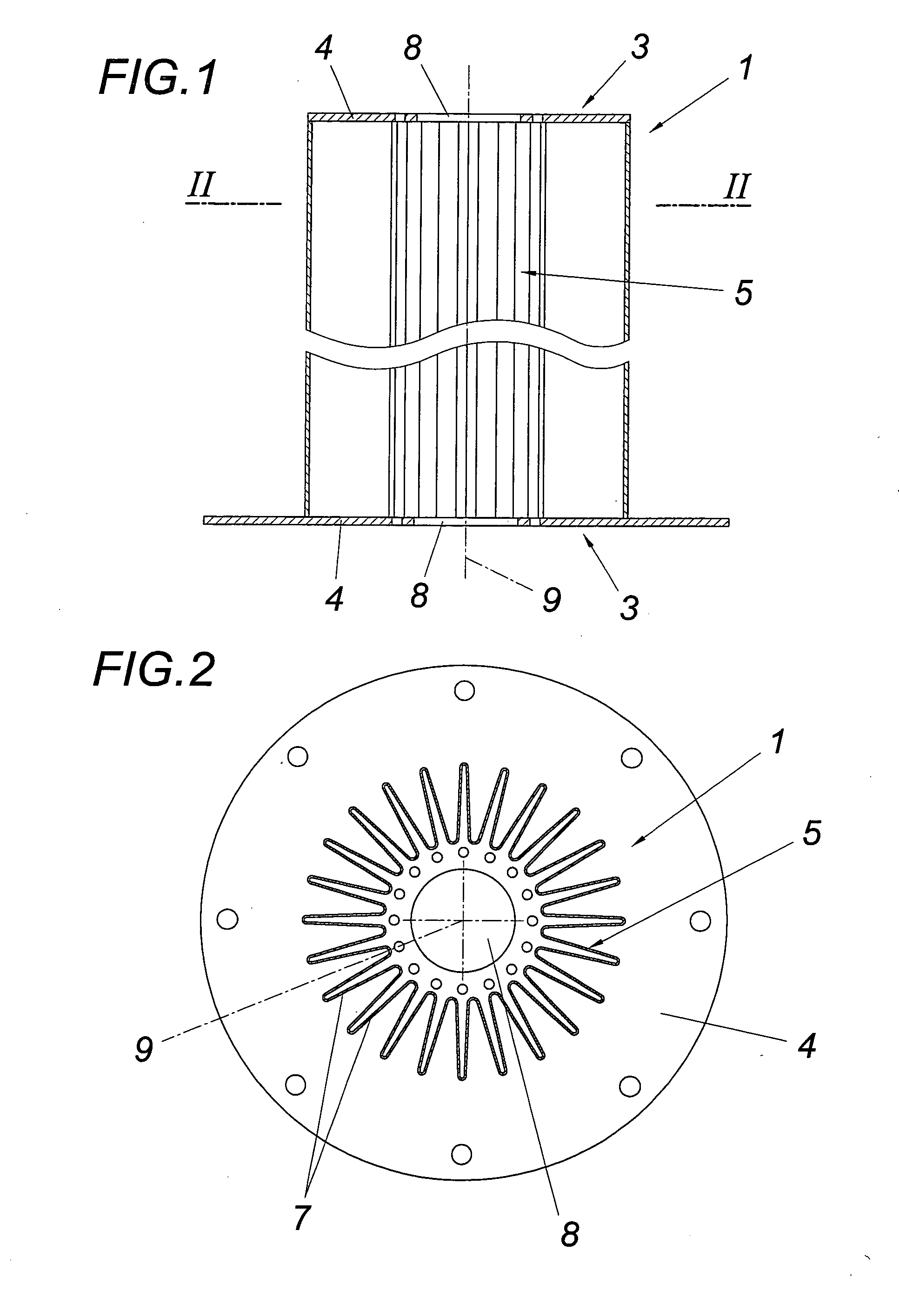

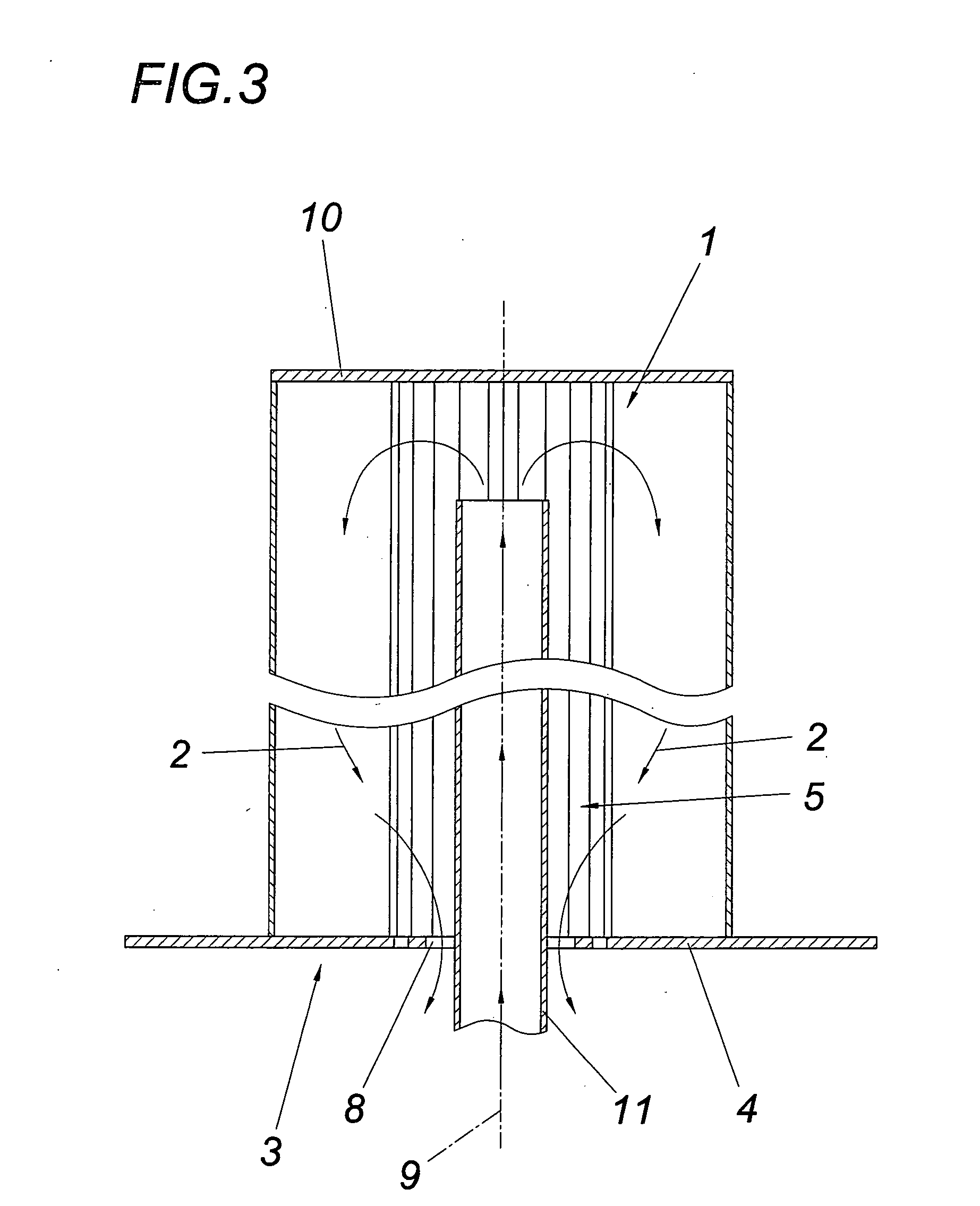

Heat exchanger for an annealing furnace for exchanging heat between two fluids

InactiveUS20110308780A1Simple and cost-effective possibilityReduce heat storage capacityMuffle furnacesRetort furnacesPlate heat exchangerEngineering

The invention relates to a heat exchanger (1) for an annealing furnace for exchanging heat between two fluids, comprising a tubular profile which comprises heat exchanger fins on its outside jacket and which is associated on at least one face side (3) with a connecting flange (4) with at least one flow opening (8) for one of the two fluids, especially a hot gas. In order to provide advantageous constructional conditions it is proposed that the profile is a profile tube made of a folded sheet whose heat exchanger fins (7) aligned in the longitudinal direction of the profile are formed by the corrugated profile, especially the corrugated flanks, of the folded sheet.

Owner:EBNER-INDUSTRIEOFENBAU GMBH

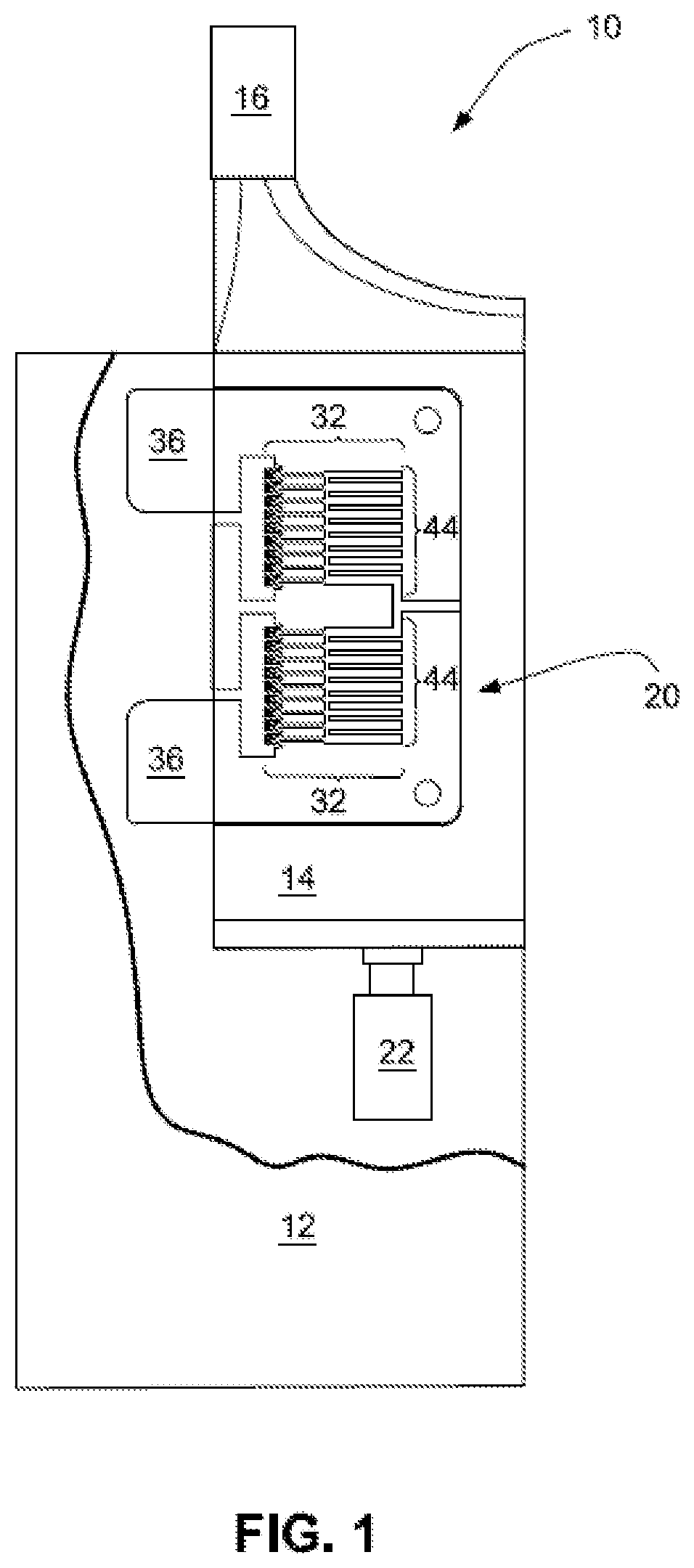

Flat heat element for microvaporizer

ActiveUS11457663B2Avoid excessive controlTemperature fluctuationOhmic-resistance heatingTobaccoEngineeringConductive materials

A heater assembly (20) is configured to vaporize a liquid. The heater assembly (20) includes a substrate plate (26,28) and a heating element (24) supported on the substrate plate (26,28). The heating element (24) includes a layer of electrically conducting material. The heater assembly (20) further includes a plurality of channels (46) formed by the electrically conducting material. Each of the plurality of channels (46) is configured to operate in parallel. Each channel (46) has an inlet end and an outlet end. The inlet end is configured to receive the liquid and the outlet end is configured to discharge vapor. The substrate plate (26,28) and the heating element (24) form a multi-layer configuration.

Owner:PHILLIPS DONOVAN +1

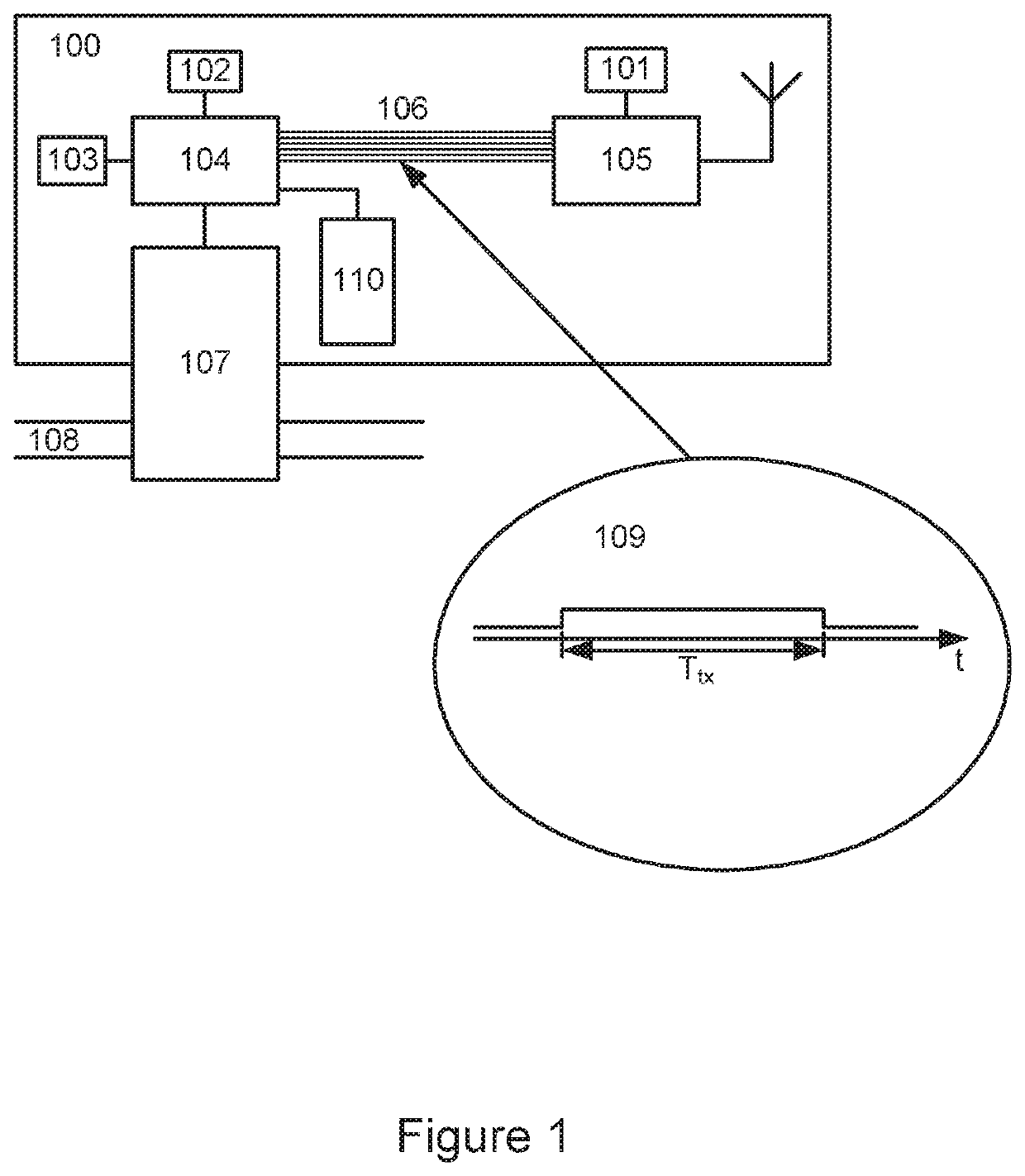

Radio communication device with high precision real time clock

ActiveUS20200279476A1Lower component costsAccurate operationSynchronisation arrangementTariff metering apparatusMicrocontrollerReal-time clock

A radio communication device comprising a radio frequency circuit and a microcontroller arranged to control the radio frequency circuit. The radio communication device further comprises: a radio frequency reference connected to the radio frequency circuit and arranged to be the frequency reference of at least the symbol frequency; a MCU and a time frequency reference connected to the microcontroller. The microcontroller is arranged to determine a frequency error of the time frequency reference relative to the radio frequency reference by performing the steps of: transmitting a radio signal, and signal a timing signal on a control interface, comprising information on start of transmission and end of transmission of the radio signal; receive the timing signal from the radio frequency circuit and measure a transmission duration of the radio signal with reference to the MCU frequency reference and calculate a frequency error of the MCU frequency reference relative to the radio frequency reference based on the measured transmission duration of the radio signal and the number of symbols and the symbol frequency. Further, the microcontroller measures a time period of the time frequency reference with reference to the MCU frequency reference; and calculate the frequency error of the time frequency reference relative to the radio frequency reference.

Owner:KAMSTRUP

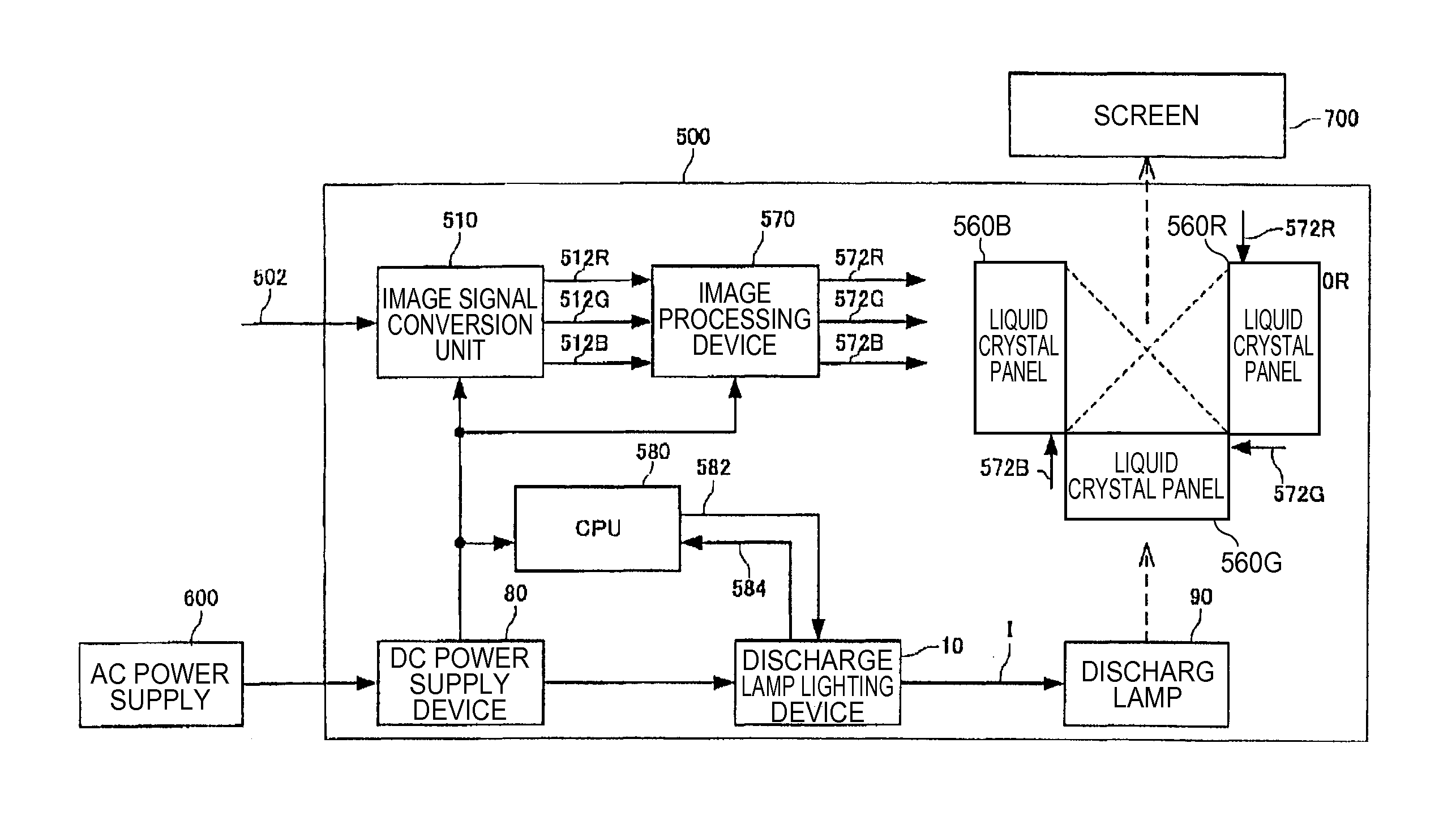

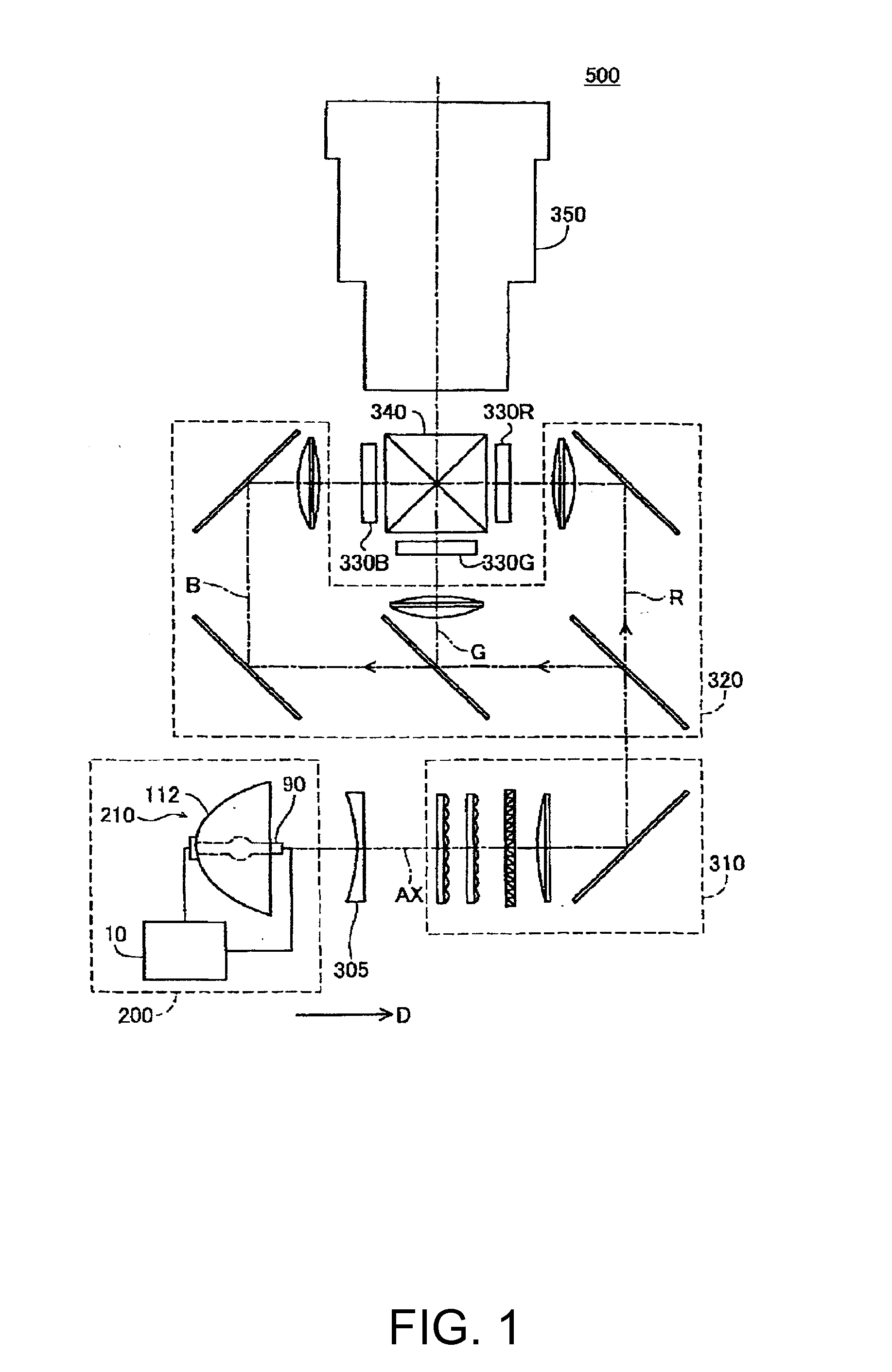

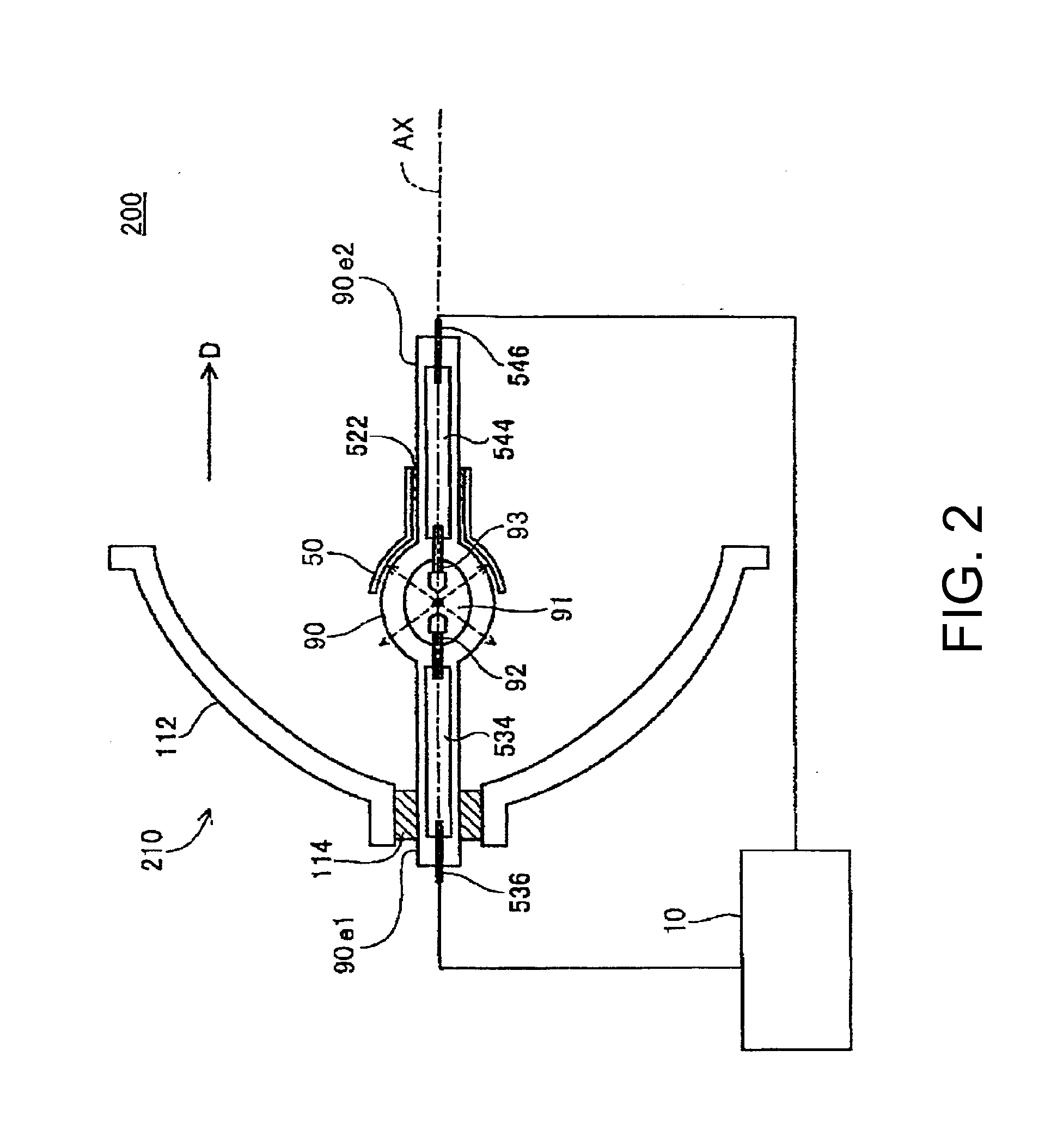

Discharge lamp driving device, light source device, projector, and discharge lamp driving method

InactiveUS20150264786A1Temperature fluctuationPrevent projectionTelevision system detailsElectric lighting sourcesLight sourceControl unit

A discharge lamp driving device includes: a discharge lamp driving unit that supplies a driving current to the discharge lamp; and a control unit that controls the discharge lamp driving unit. The driving current having driving periods is supplied, the driving period including: a mixing period which alternately has an AC period in which an alternating current is supplied and a first DC period in which a direct current is supplied, a second DC period which is provided immediately after the mixing period and in which a direct current having a polarity which is the same as that of the direct current in the first DC period is supplied, and a third DC period which is provided immediately after the second DC period and in which a direct current having a polarity opposite to that of the direct current in the second DC period is supplied.

Owner:SEIKO EPSON CORP

A real-time detection device for bolt preload degradation process considering high temperature creep

ActiveCN105043741BRecord degradation data in real timeEasy to assembleMachine part testingMeasurement of torque/twisting force while tighteningSimulationData acquisition

A real-time detection device for the degradation process of bolt preload force considering high temperature creep, the detection device includes a preload force acquisition system (A), a bolt clamping connection device system (B) and a heating system (C), and the three are connected to each other . The detection device has a low construction cost, is small in size, is easy to carry, and is convenient for simulating high-temperature creep in a real environment. The invention can provide a high-temperature environment, accurately simulate the creep process of the bolt during use, and simultaneously collect the value of the pretightening force in real time and feed it back to the computer. It has good application prospects in the field of engineering material testing instruments and equipment technology.

Owner:电科北方数字科技(山东)有限公司

Light source and atomic oscillator

InactiveUS20170117910A1Avoid layeringSuppresses temperature changesLaser detailsPulse automatic controlElectrical conductorQuantum well

A light source includes an optical oscillation layer having a first reflective layer, an active layer, and a second reflective layer laminated therein in this order; an electrical field absorption layer having a first semiconductor layer, a quantum well layer, and a second semiconductor layer laminated therein in this order; and a heat insulating layer that is disposed between the optical oscillation layer and the electrical field absorption layer and has a lower thermal conductivity than that of the second reflective layer.

Owner:SEIKO EPSON CORP

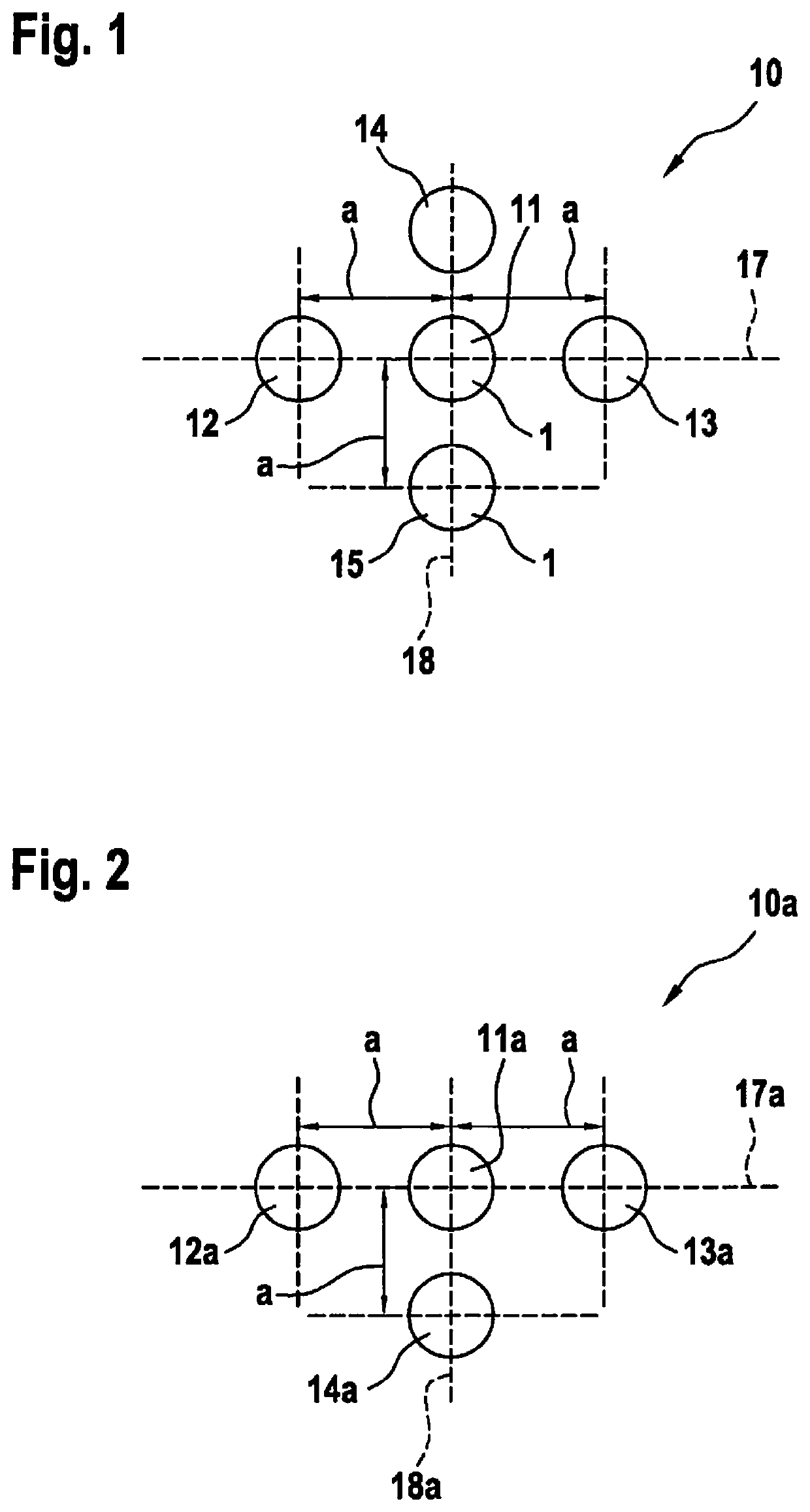

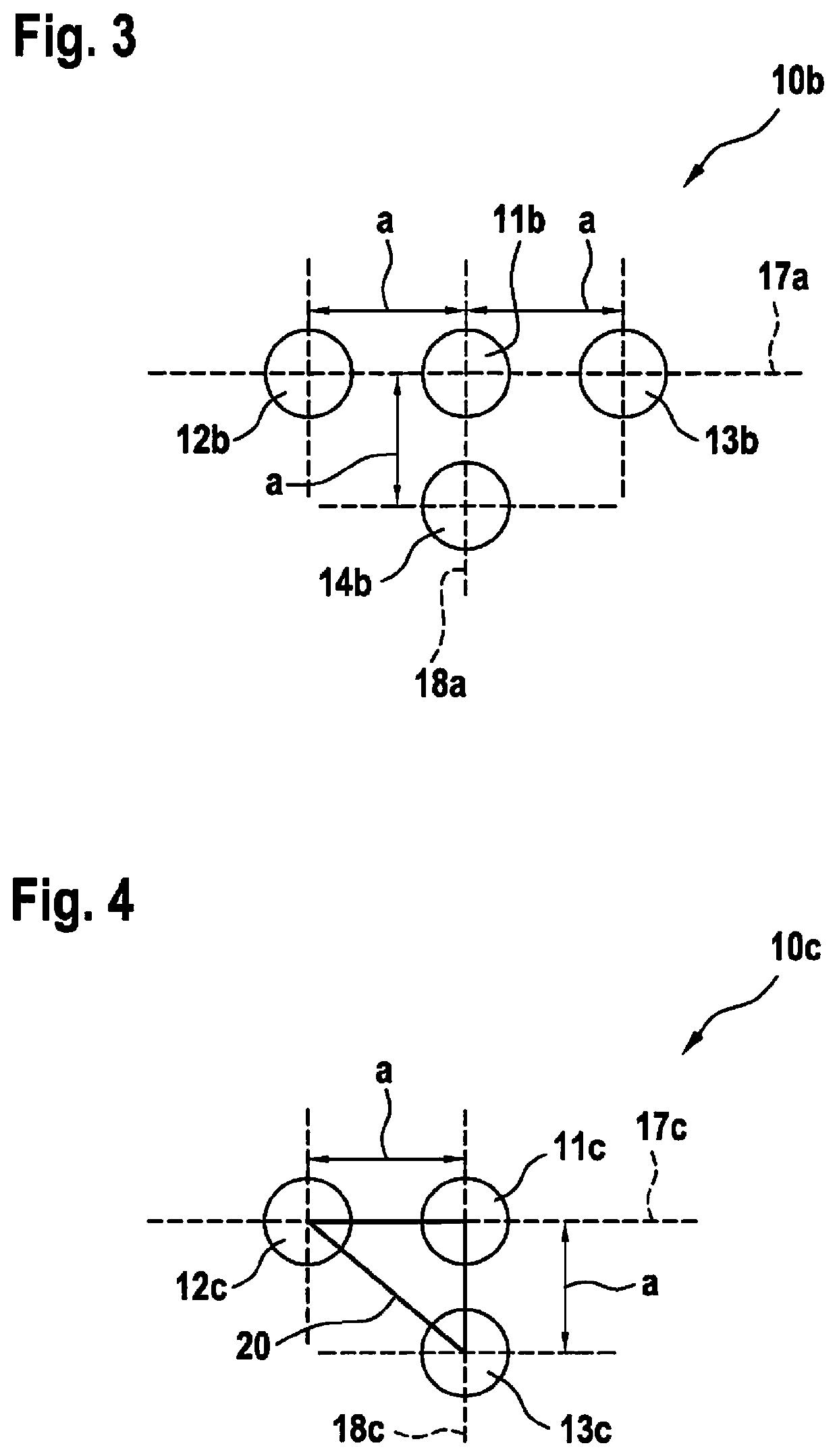

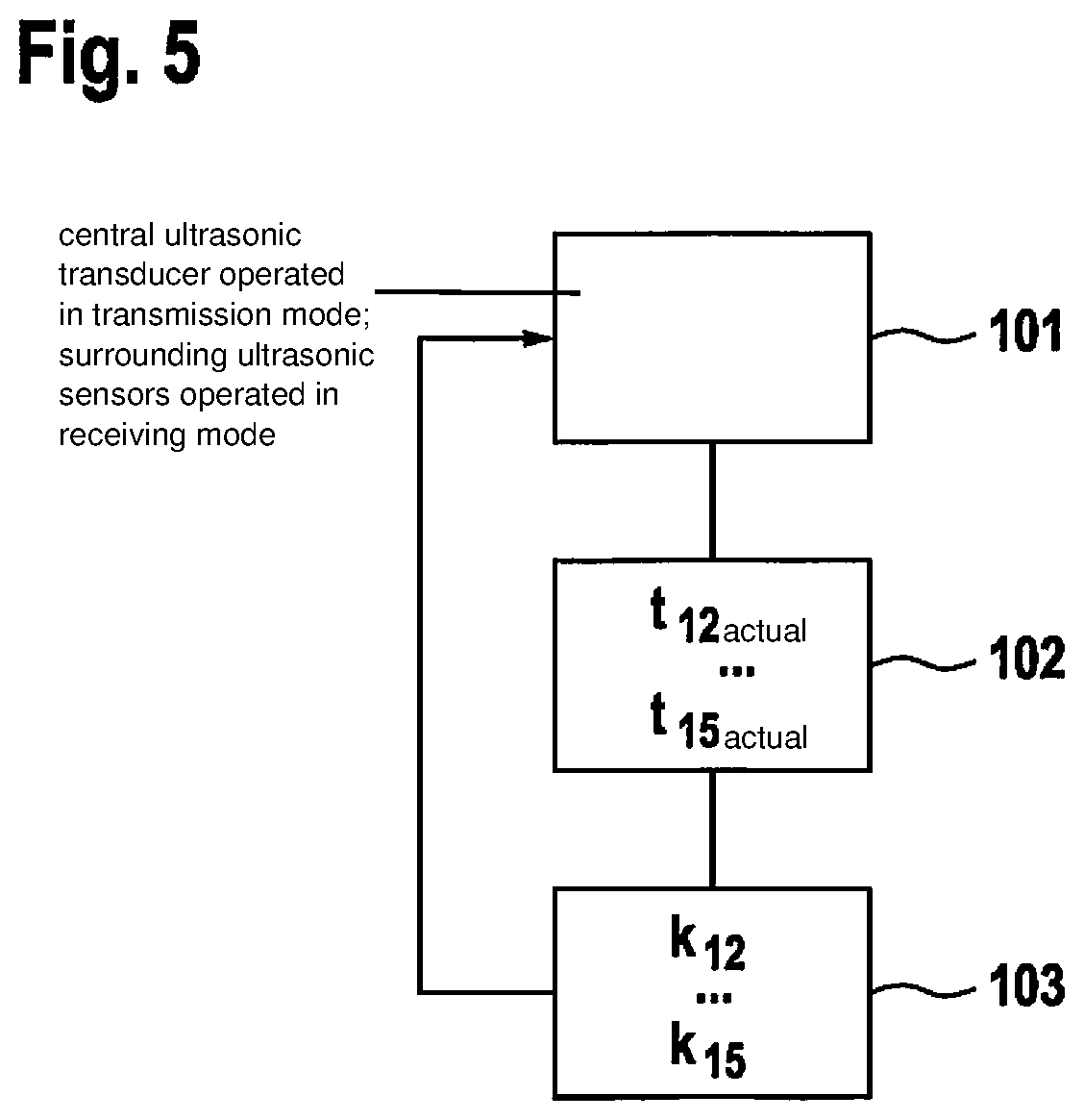

Method for calibrating ultrasonic transducers and system for carrying out the method

ActiveUS11320524B2Improved and precise measurementEasy to measureAcoustic wave reradiationUltrasonic sensorTransducer

Owner:ROBERT BOSCH GMBH

Radio communication device with high precision real time clock

ActiveUS10922960B2High precisionIncreasing consumptionSynchronisation arrangementTransmission systemsMicrocontrollerReal-time clock

A radio communication device comprising a radio frequency circuit and a microcontroller arranged to control the radio frequency circuit. The radio communication device further comprises: a radio frequency reference connected to the radio frequency circuit and arranged to be the frequency reference of at least the symbol frequency; a MCU and a time frequency reference connected to the microcontroller. The microcontroller is arranged to determine a frequency error of the time frequency reference relative to the radio frequency reference by performing the steps of: transmitting a radio signal, and signal a timing signal on a control interface, comprising information on start of transmission and end of transmission of the radio signal; receive the timing signal from the radio frequency circuit and measure a transmission duration of the radio signal with reference to the MCU frequency reference and calculate a frequency error of the MCU frequency reference relative to the radio frequency reference based on the measured transmission duration of the radio signal and the number of symbols and the symbol frequency. Further, the microcontroller measures a time period of the time frequency reference with reference to the MCU frequency reference; and calculate the frequency error of the time frequency reference relative to the radio frequency reference.

Owner:KAMSTRUP

A low-nox gas burner with multi-nozzle dispersed combustion

InactiveCN103471101BEvenly distributedLower combustion temperatureGaseous fuel burnerFuel distributionEngineering

The invention provides a multi-spray-nozzle bulky combustion low-NOx gas combustor, which comprises a heat insulation tile, a first-stage combustor, a second-stage combustor, a first-stage fuel distribution pipe and an air box, wherein a first passage and a second passage are arranged on the heat insulation tile, the lower end of the heat insulation tile is connected with the upper end of the air box, in addition, the first passage is communicated with a cavity of the air box, the first-stage fuel distribution pipe is arranged in the first passage and the cavity of the air box, the second-stage combustor is arranged in the second passage, the top end of the first-stage fuel distribution pipe is provided with a hemispherical sealed surface, the tail end of the first-stage combustor is arranged on the hemispherical sealed surface, and in addition, the inside of the first-stage fuel distribution pipe is communicated with the inside of the first-stage combustor. The multi-spray-nozzle bulky combustion low-NOx gas combustor technically synthesizes fuel grading, smoke gas recirculation and multipoint bulky combustion control techniques, and has the characteristics that long flame in multipoint bulky combustion can be formed, the peak temperature of the combustion flame is reduced, the distribution of heat loads in a furnace is uniform, and the generation amount of NOx is ultralow.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

System and method for determining the thermal properties of rocks under high pressure conditions in deep sea

InactiveUS10345253B2Easy to operateHeating sourceThermometer detailsMaterial heat developmentEngineeringRock sample

A system for determining the thermal properties of rocks under high pressure conditions in deep sea includes a first pressure vessel having a data collecting unit and a second pressure vessel having a chamber being filled with seawater, communicating with a drain valve, and having a rock sample disposed therein. First and second temperature sensors are respectively disposed in the center and on the surface of the rock sample. A third temperature sensor and a pressure sensor are disposed in the chamber. Outputs of the temperature sensors and the pressure sensor are communicated with inputs of the data collecting unit via watertight cables. Determining the thermal properties of rocks under high pressure conditions in deep sea includes rapidly opening the drain valve for instant loading of the rock sample and introducing an established finite element numerical inversion model. No heat source for electrical heating nor booster pump is needed.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com