Vertical sludge drying, gasifying and incinerating integrated treatment device and method

A sludge drying and treatment device technology, which is applied in the field of gasification, can solve the problems of inability to purify combustible gas, recovery of waste heat in the gasification chamber, poor overall environmental protection, etc., achieve ideal heat exchange effect, improve utilization rate, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

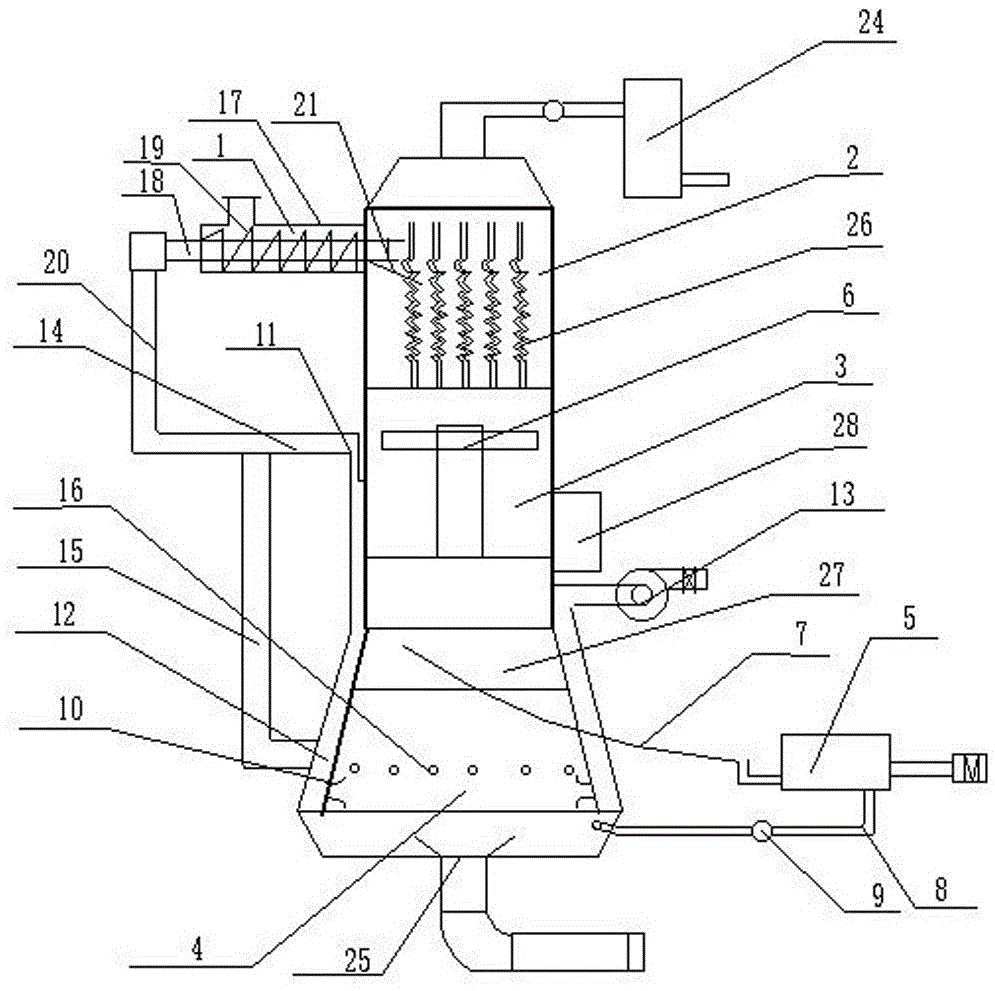

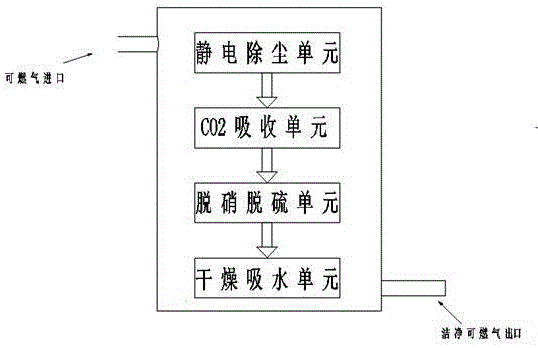

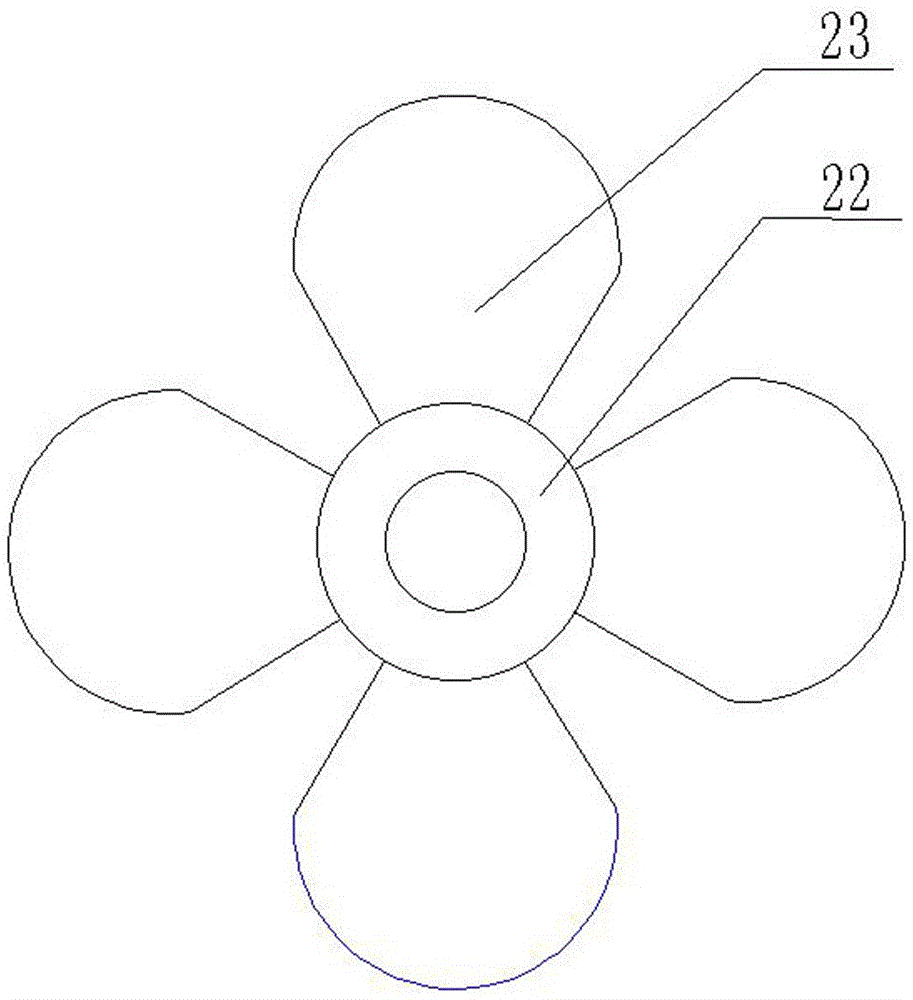

[0030] As shown in the figure, a vertical sludge drying gasification incineration integrated treatment device includes an electric control room 28, a feeding mechanism 1 for transporting wet sludge, a drying chamber 2 for drying wet sludge, and a The gasification chamber 3 for the gasification reaction of the dried sludge, the combustion chamber 4 for incinerating the sludge, and the crushing and mixing mill 5 for delivering fuel to the combustion chamber 4, the drying chamber 2, the gasification chamber 3 and the combustion chamber The chamber 4 is arranged sequentially from top to bottom, and the outlet of the feeding mechanism 1 is arranged in the drying chamber 2. The top of the drying chamber 2 is provided with an air outlet, and the drying chamber 2 is provided with multiple rows of connected air outlets and air outlets. The combustible gas passage 26 of the gasification chamber 3, the middle part of the combustible gas passage 26 adopts a spiral structure, so as to trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com