A low-nox gas burner with multi-nozzle dispersed combustion

A gas burner and multi-nozzle technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as local high-temperature combustion instability, and achieve the effects of reducing NOx generation, lowering combustion temperature, and promoting mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

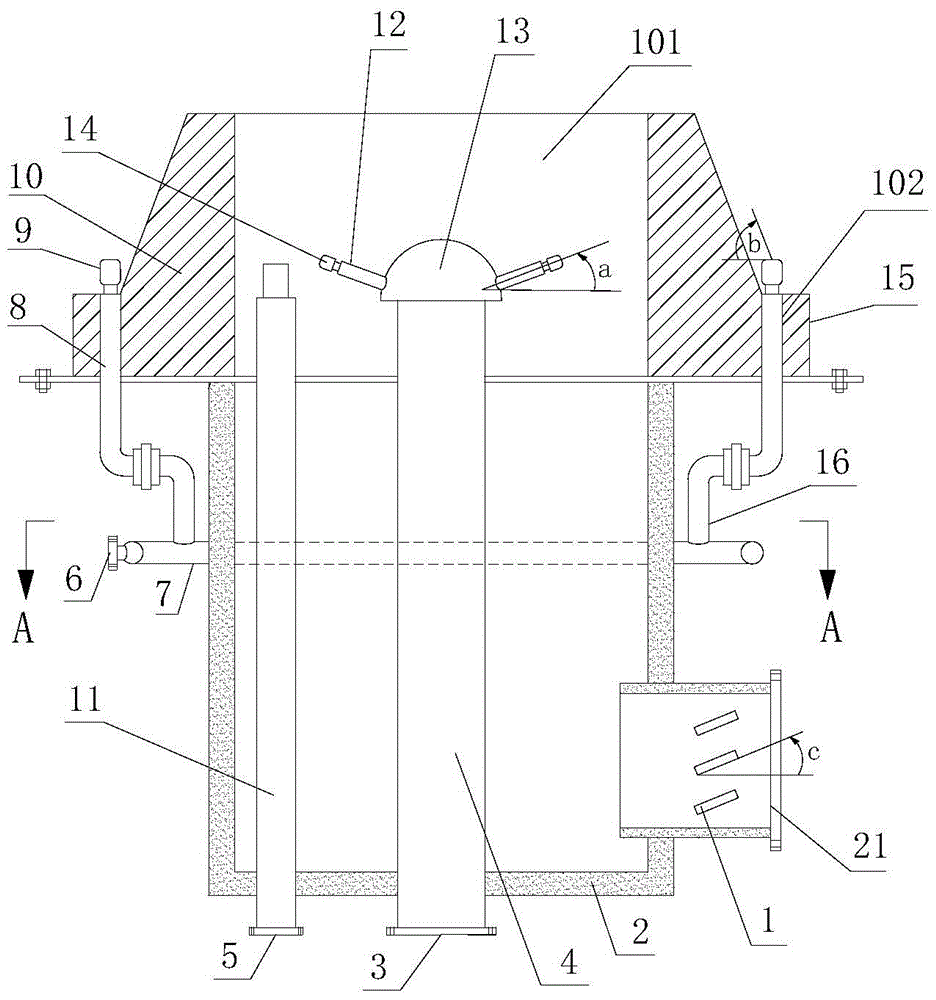

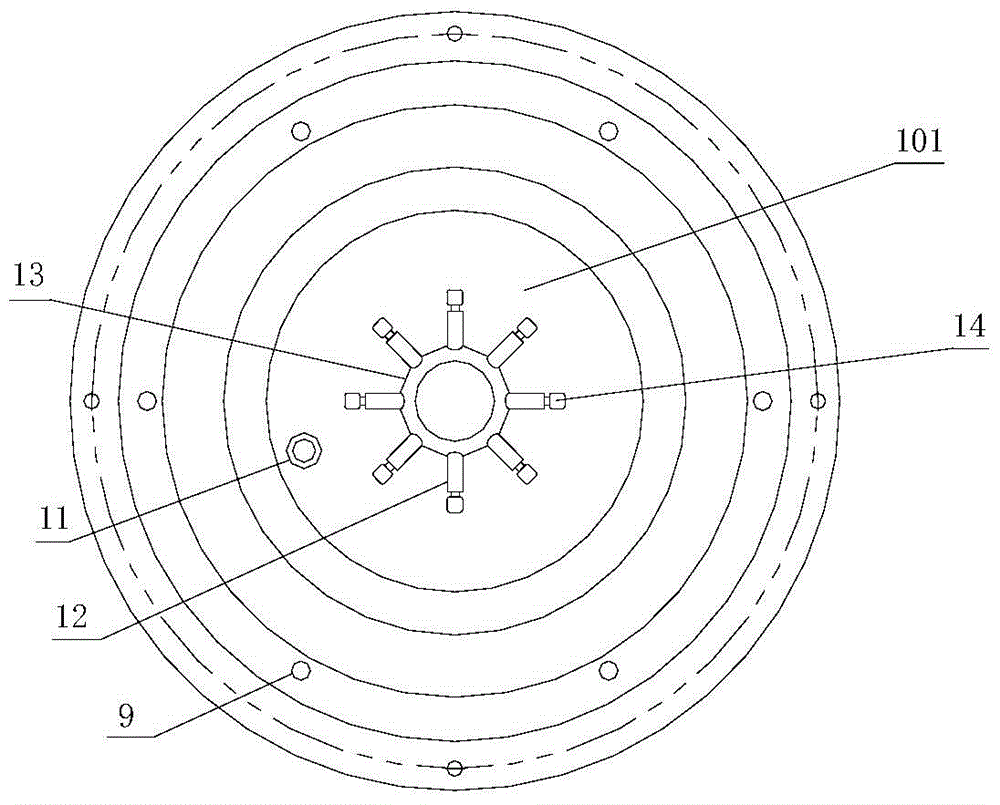

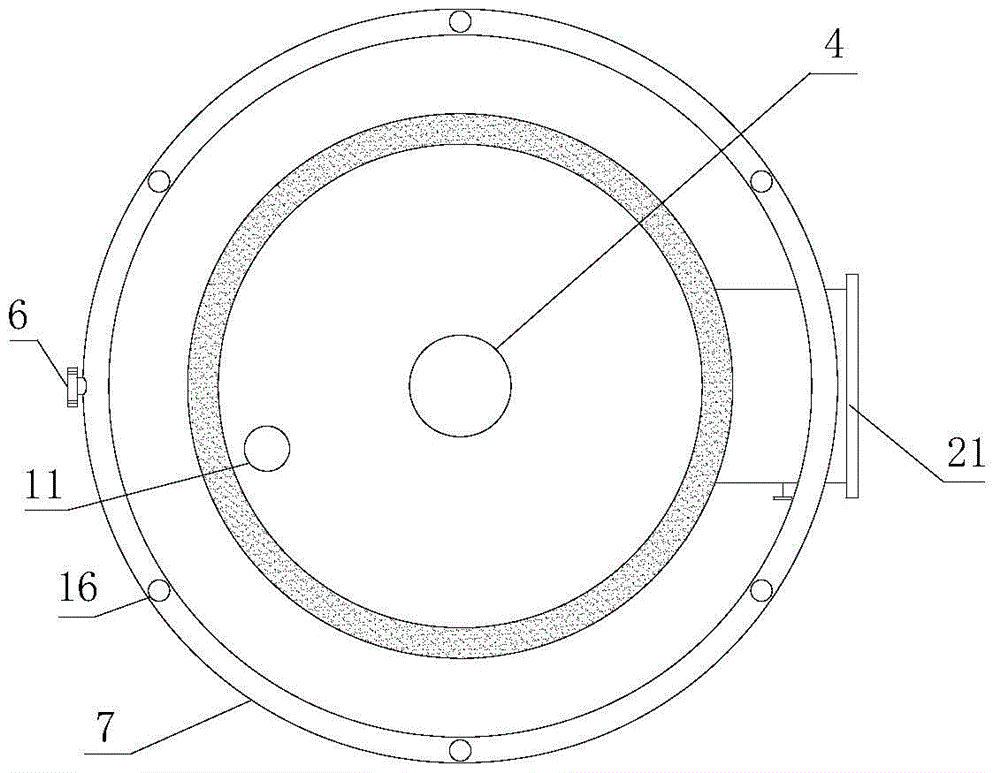

[0038] A low NOx gas burner with multi-nozzle dispersed combustion, see figure 1 , figure 2 as well as image 3 , including a heat insulating tile 10, a first-stage burner 12, a second-stage burner 8, a first-stage fuel distribution pipe 4, an auxiliary burner 11 and an air box 2.

[0039] The longitudinal central axis of the heat insulating tile 10 is provided with a first passage 101, and the periphery of the first passage 101 is provided with a second passage 102 at equal intervals. The lower end of the heat insulating tile 10 and the upper end of the wind box 2 connected, and the first channel 101 communicates with the cavity of the air box 2, which can enhance the mixing of gas and combustion air; the second-stage burners 8 are evenly arranged along the outer circumference of the heat insulating tile 10, which can strengthen the heat load distribution in the furnace uniformity.

[0040] The lower end of the bellows 2 is provided with an air inlet 21, and the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com