A real-time detection device for bolt preload degradation process considering high temperature creep

A technology for bolt pre-tightening and real-time detection, which is used in measuring devices, using stable tension/pressure to test material strength, and testing of mechanical parts, etc. Obtaining bolt pretightening force degradation data, high price and other problems, to achieve the effect of low construction cost, easy maintenance and replacement, and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific examples of the present invention, and the technical solutions of the present invention are further described with reference to the accompanying drawings, but the present invention is not limited to the following examples.

[0030] In the high-temperature working environment of the engine rotor bolt, the pre-tightening force is degraded due to high-temperature creep. The maximum working temperature is 500 °C, and the initial pre-tightening force is set to 15kN. Now simulate the actual working temperature, detect the degradation process of the preload force in real time, and obtain the preload force degradation curve.

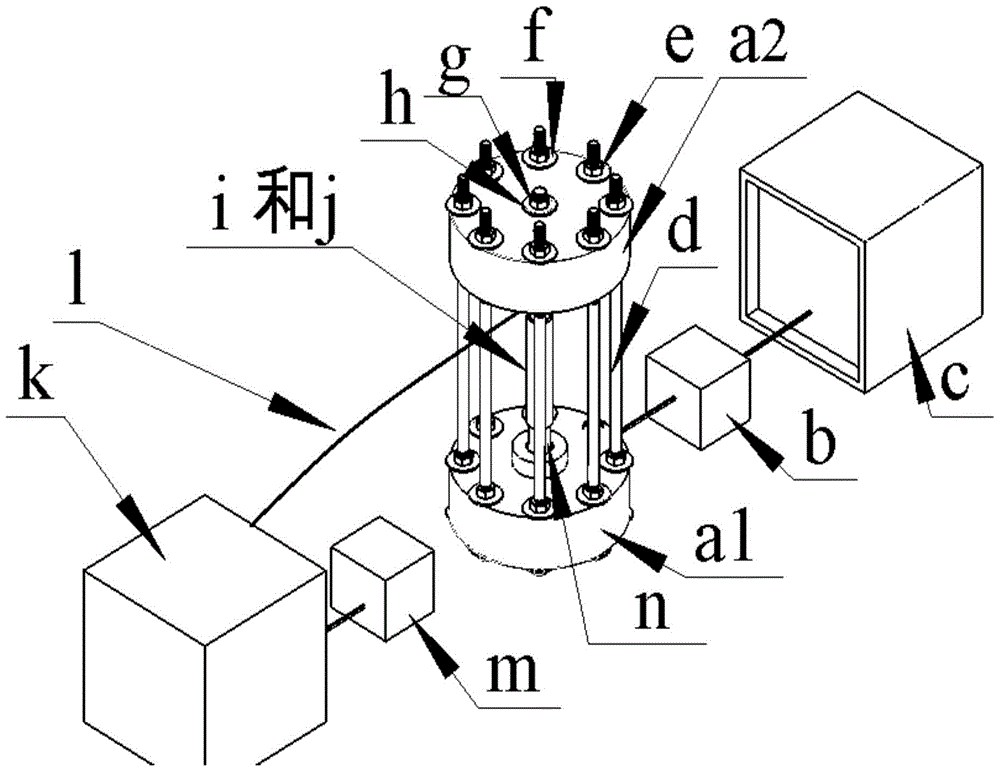

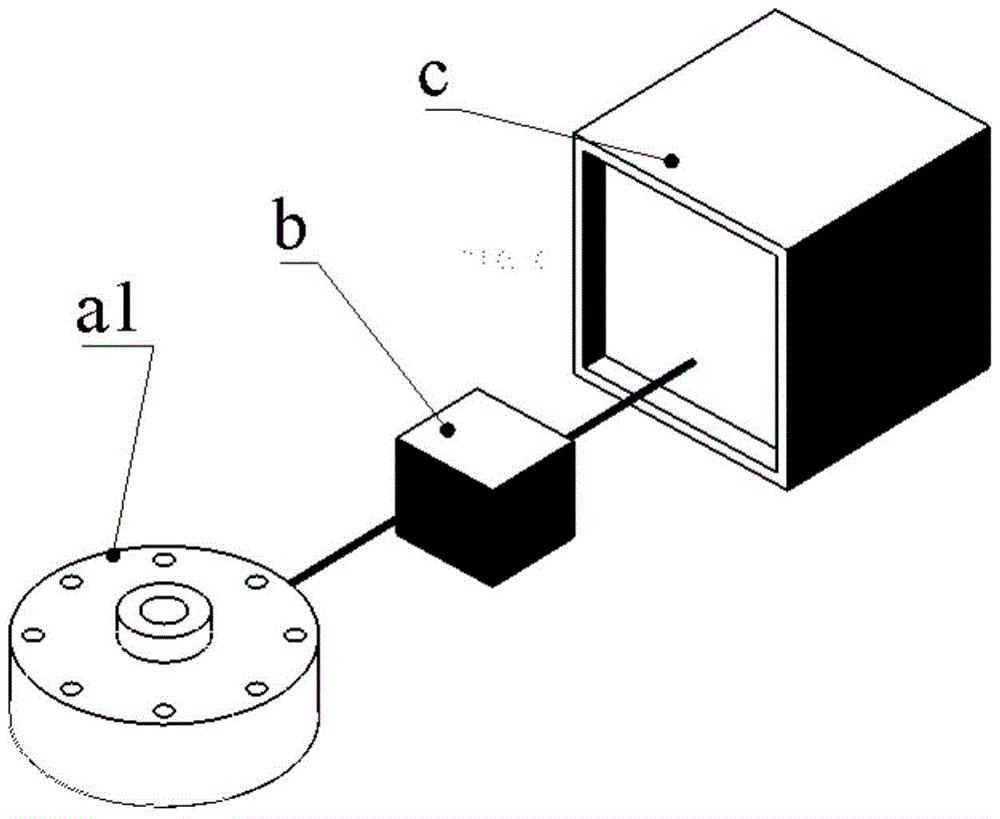

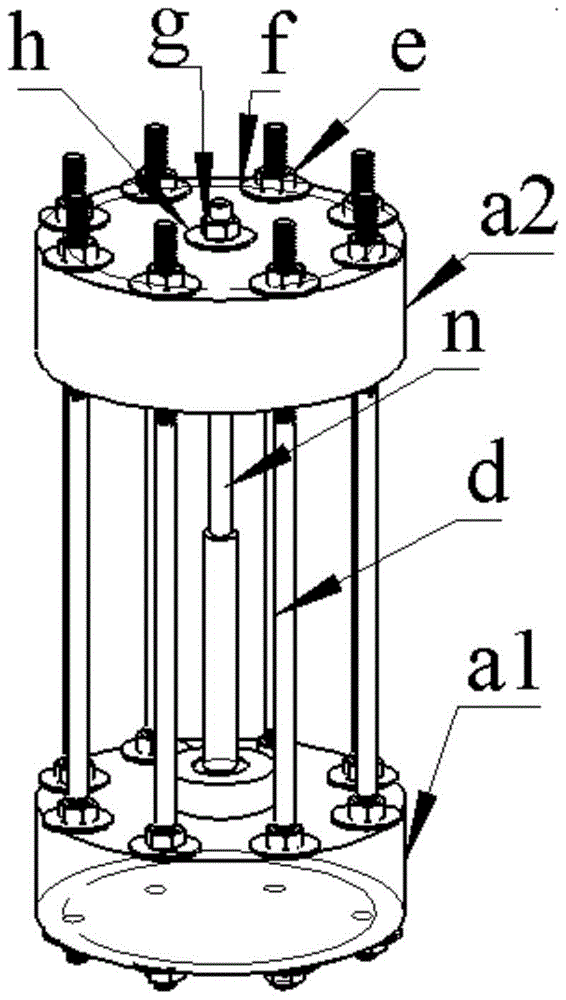

[0031] The technical solution adopted in the present invention is a real-time detection device for the degradation process of bolt pretightening force considering high temperature creep, such as figure 1 shown. The device includes three system units, namely, a pre-tightening force acquisition system A, a bolt clamping connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com