Organic plastic scintillator and preparing method thereof and light conversion device

An organic plastic and scintillator technology, which is applied in the direction of conversion screens, instruments, optics, etc., can solve the problems of inability to achieve n-γ resolution, the performance of plastic scintillators is reduced, and the human body is injured. Yield, simple formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing an organic plastic scintillator, which comprises: degassing the clear night of a vinyl toluene solution dispersed with 2,5-diphenyloxazole in a sealed container, and heating it to 125-150 for the first time After reacting at ℃ for 4-8 hours, slowly cool to room temperature to obtain a precursor; heat the precursor to 120-140 ℃ for the second time to solidify and then cool to room temperature.

[0025] Using 2,5-diphenyloxazole and vinyltoluene solution as raw materials, the formula is simple, the purity of the scintillator is guaranteed, and the operation is more convenient.

[0026] A specific preparation method for clearing the vinyl toluene solution dispersed with 2,5-diphenyloxazole is: adding 2,5-diphenyloxazole to vinyl toluene in proportion, and ultrasonically dispersing to 2 ,5-Diphenyloxazole was completely dissolved in vinyltoluene. The ultrasonication time is about 15 minutes. After dissolving, it is observed tha...

Embodiment 1

[0045] A preparation method of an organic plastic scintillator, comprising:

[0046] Weigh 0.5g of 2,5-diphenyloxazole, add it into a weighing bottle containing 10g of vinyl toluene, and ultrasonically disperse it for about 15min, and filter the ultrasonically dispersed PPO / PVT solution with a special filter head for the organic phase, The filtrate was injected into a glass bottle with a rubber stopper, and the rubber stopper was covered. Insert a needle for injection on the rubber stopper, pump air with a vacuum pump for 15 minutes, turn off the vacuum pump, fill the bottle with nitrogen for 1 minute with the needle, and stop the inflation. Repeat the pumping and inflation operation once. Put the treated reaction bottle in an oil bath and heat it to 125°C for 4 hours. After the reaction, set the oil bath to 95°C, 65°C, and 35°C respectively. Turn off the heating, take out the reactant, and obtain the precursor. The precursor reactants were put into a muffle furnace and hea...

Embodiment 2

[0048] A method for preparing an organic plastic scintillator, which differs from Example 1 in that the mass of 2,5-diphenyloxazole is 1.0 g.

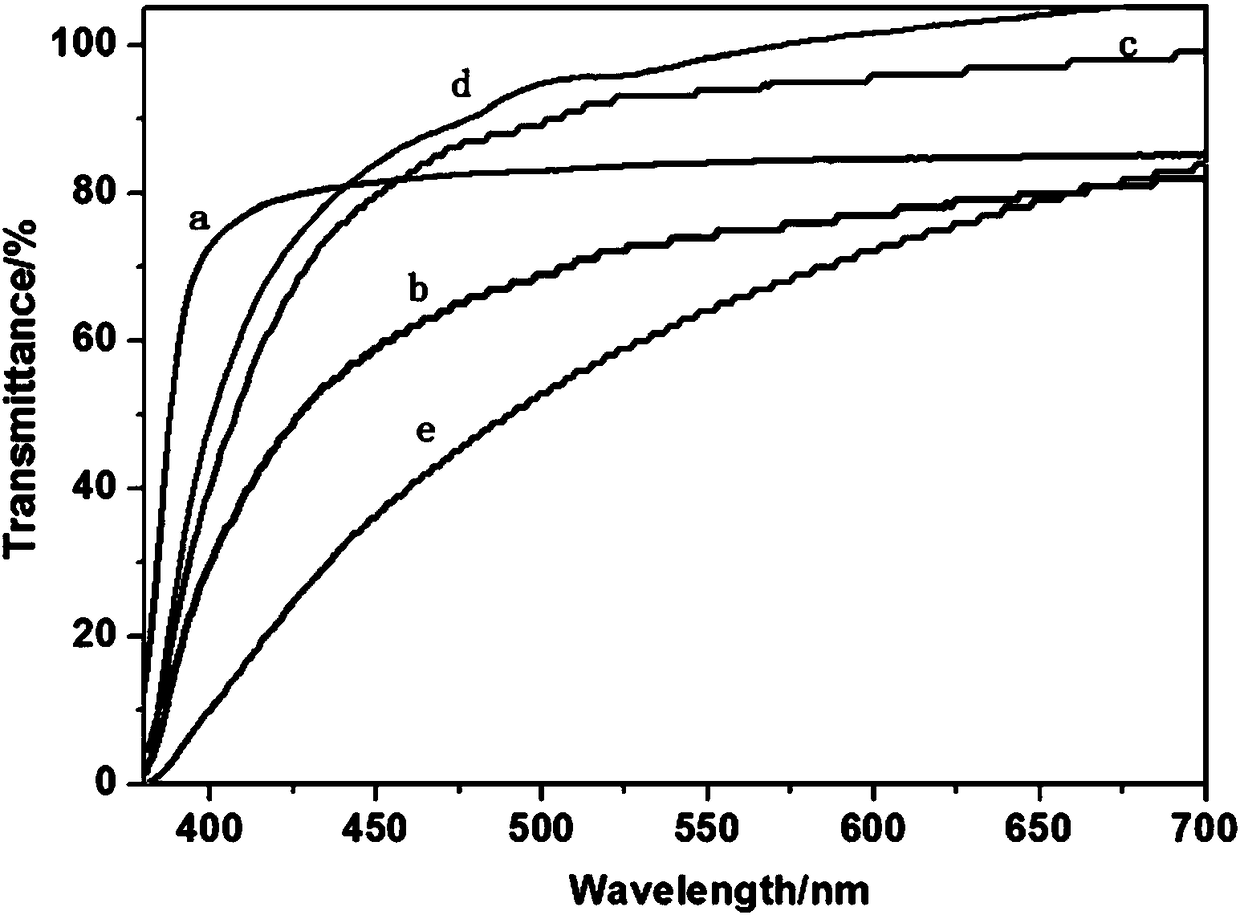

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com