High-hydrophobicity high temperature-resistant fluorescent coating preparation method

A fluorescent coating and high hydrophobicity technology, applied in coatings, luminous coatings, etc., can solve problems such as instability, uneven luminescence, and uneven coordination of rare earths, and achieve reduced dosage, uniform luminescence, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

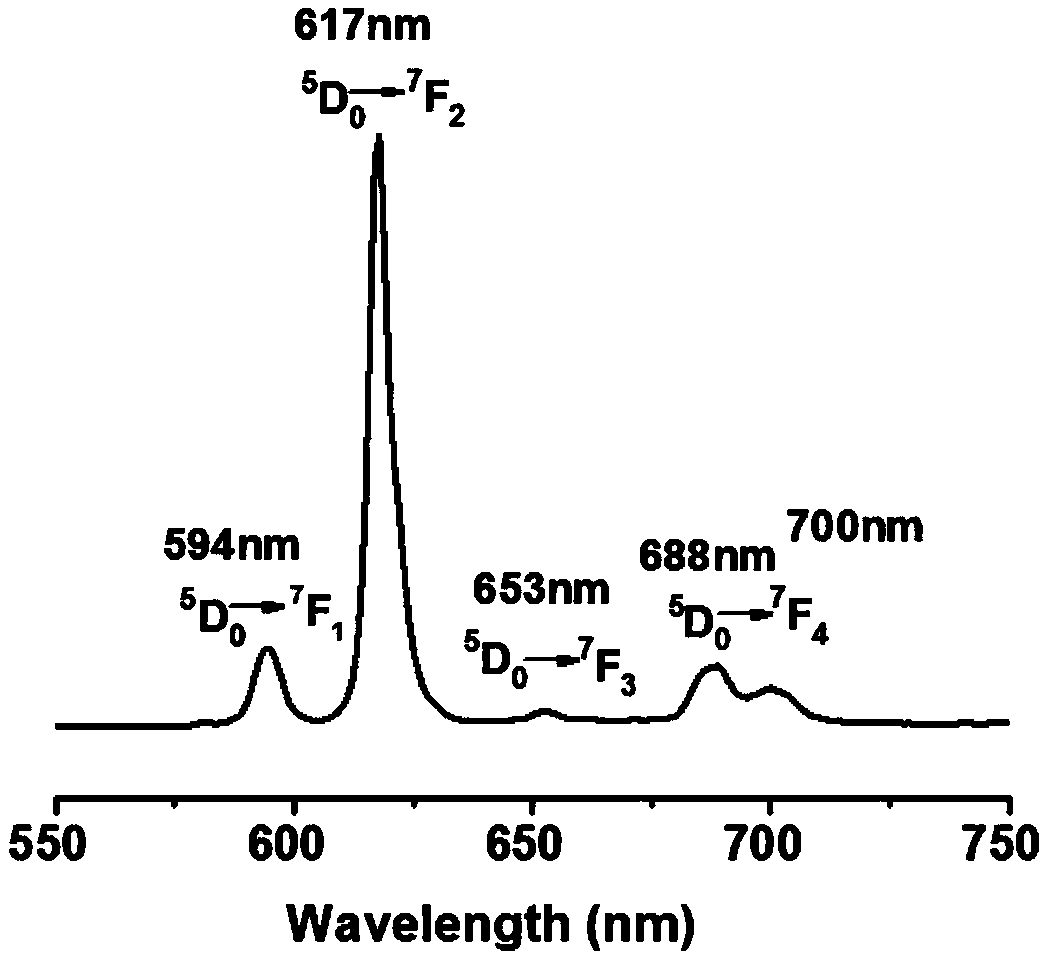

[0027] Add 14g of divinylbenzene dropwise to a solution containing 0.15g of sodium dodecylsulfonate, 0.45g of cetyl alcohol, and 60mL of deionized water to form a pre-emulsion. Next, add 5mL aqueous solution containing 0.03g potassium persulfate and react for 10h; dropwise add monomer solution consisting of 7g divinylbenzene, 1g acrylic acid, 0.2g sodium dodecylsulfonate, 20mL water and 0.018g A 30mL aqueous solution composed of sodium persulfate was added dropwise and reacted at 70°C for 4h to obtain a core-shell emulsion with an average particle size of 1um. Centrifuge the prepared core-shell emulsion and disperse it in ethanol solution, add o-phenanthroline, benzoylacetone and europium nitrate to the system and stir for 1 hour to obtain a suspension, wherein carboxyl particles: o-phenanthroline: benzoyl The ratio of acetone: europium chloride is 1:2:1:1; the suspension with a solid content of 0.05g / mL after coordination is spin-coated on a glass slide to obtain a highly hyd...

Embodiment 2

[0029] Add 12g of divinylbenzene dropwise to a solution containing 0.6g sodium lauryl sulfate, 0.6g hexadecane, and 96mL of deionized water to form a pre-emulsion, and after ultrasonication for 6min in an ice-water bath, at 70°C , add 5mL aqueous solution containing 0.04g potassium persulfate, react for 7h; add dropwise a monomer solution consisting of 7g divinylbenzene, 3g 4-vinylbenzoic acid, 0.25g sodium dodecyl sulfate, and 25mL water And 35mL of aqueous solution composed of 0.05g of potassium persulfate, while adding dropwise, react at 75°C for 3h to obtain a core-shell emulsion with an average particle size of 800m. Centrifuge the prepared core-shell emulsion and disperse it in the acetone solution, add 8-hydroxyquinoline, caproyl acetone and terbium nitrate to the system, stir for 3 hours, wherein carboxyl particles: 8-hydroxyquinoline: caproyl acetone: nitric acid The ratio of the amount of terbium to substance is 1:2:2:1; the suspension with a solid content of 0.008g / ...

Embodiment 3

[0031] Add 14g of divinylbenzene dropwise to a solution containing 0.4g of potassium dodecylsulfonate, 1g of cetyl alcohol, and 80mL of deionized water to form a pre-emulsion. , add 5mL aqueous solution containing 0.08g ammonium persulfate, after reacting for 7h; dropwise add monomer solution composed of 8g divinylbenzene, 5.2g methacrylic acid, 0.4g potassium dodecylsulfonate, 40mL water and A 30 mL aqueous solution composed of 0.04 g of potassium persulfate was added dropwise and reacted at 70° C. for 5 h to obtain a core-shell emulsion with an average particle size of 1.5 μm. Filter the prepared core-shell emulsion and disperse it in the tetrahydrofuran solution, add acetylacetone and europium chloride to the system, stir for 2 hours to obtain a suspension, in which the ratio of carboxyl particles: acetylacetone: europium chloride is 1 :3:1, the suspension with a solid content of 0.007g / mL after coordination was ultrasonicated for 5min, poured and coated on a glass slide to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com