Core-double-shell structure composite nickel-cobalt-manganese ternary precursor material and preparation method and application thereof

A shell structure, nickel-cobalt-manganese technology, applied in the core-double-shell structure composite nickel-cobalt-manganese ternary precursor material and its preparation field, can solve the problems affecting the service life, cycle life deviation and high temperature cycle of power batteries for new energy vehicles Performance deviation and other issues, to achieve good cycle performance, high specific energy, and the effect of inhibiting irreversible phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

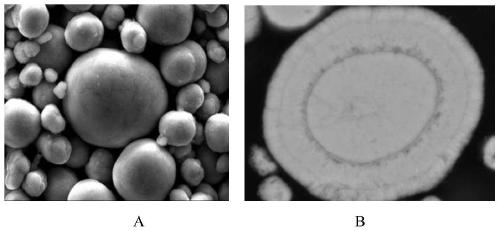

[0071] The core-double-shell structure composite nickel-cobalt-manganese ternary precursor material includes a core, a subshell layer and an outermost layer, the subshell layer is coated on the outer surface of the core, and the outermost layer is coated on the outer surface of the subshell layer , where: the chemical formula of the core material is Ni 0.15 co 0.15 mn 0.70 CO 3 ; The chemical formula of the subshell material is Ni 0.80 co 0.10 mn 0.10 (OH) 2 ; The outer shell material is aluminum hydroxide. Among them, the particle size of the inner core is 5 μm, the thickness of the subshell layer is 3 μm, and the thickness of the outermost layer is 500 nm. The diameter of the micropores in the shell layer is 0.3 μm.

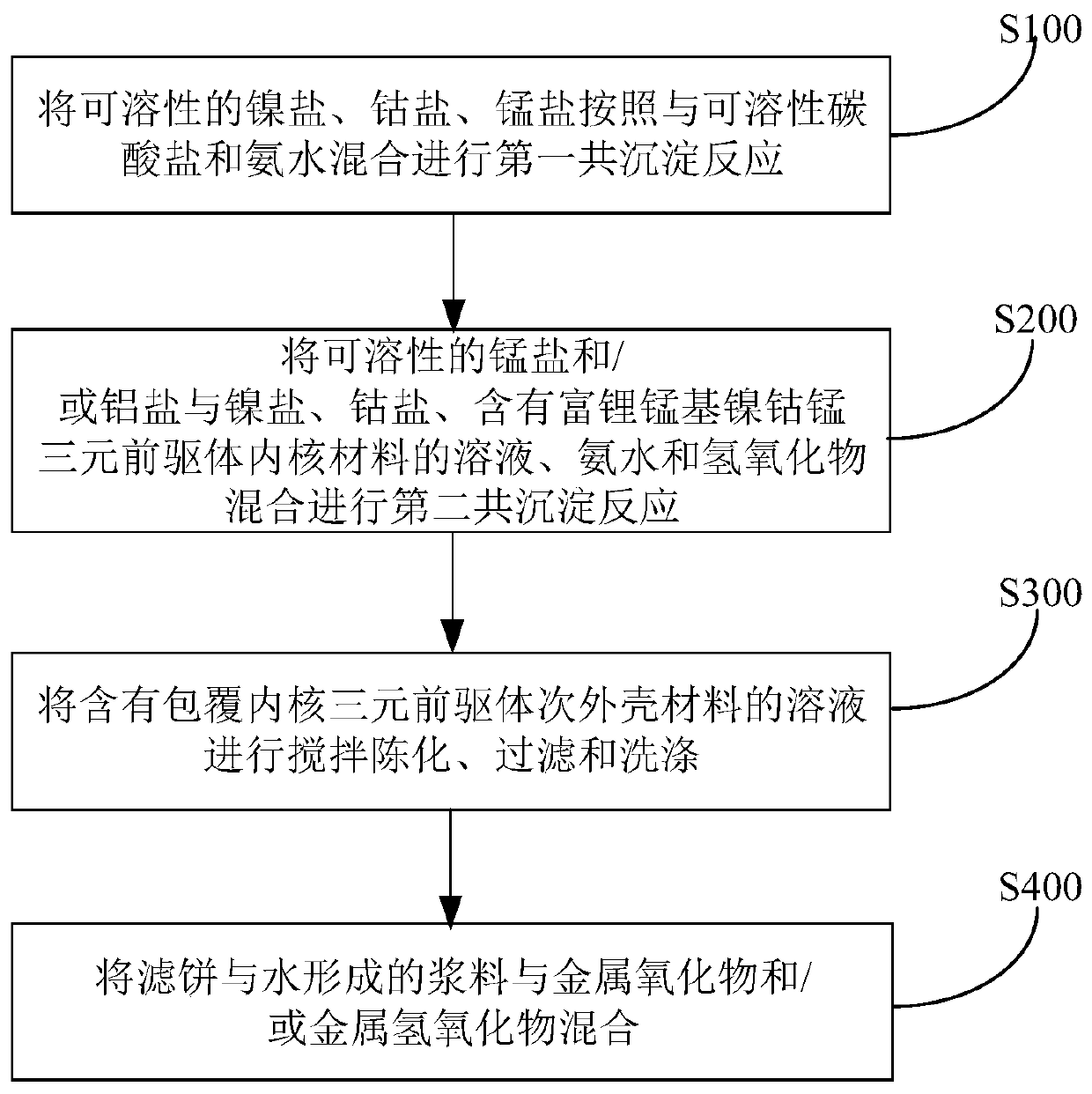

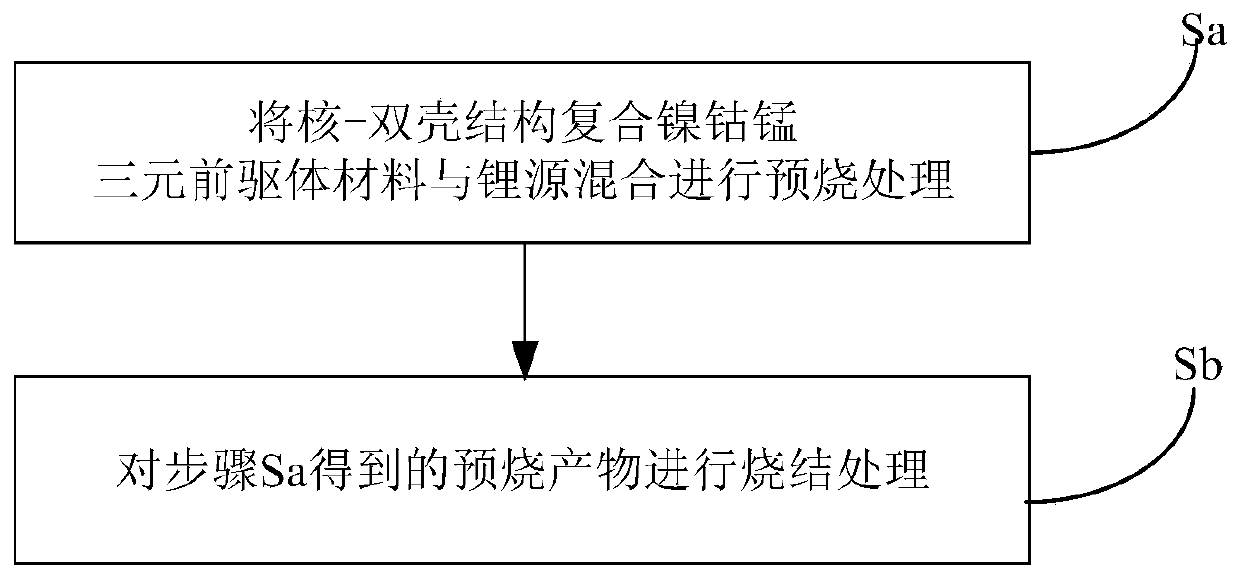

[0072] The method for preparing the core-double shell structure composite nickel-cobalt-manganese ternary precursor material is as follows:

[0073] (1) The core material is a lithium-rich manganese-based nickel-cobalt-manganese ternary cathode materia...

Embodiment 2

[0082] The core-double-shell structure composite nickel-cobalt-manganese ternary precursor material includes a core, a subshell layer and an outermost layer, the subshell layer is coated on the outer surface of the core, and the outermost layer is coated on the outer surface of the subshell layer , where: the chemical formula of the core material is Ni 0.15 co 0.15 mn 0.70 CO 3 ; The chemical formula of the subshell material is Ni 0.90 co 0.07 Al 0.03 (OH) 2 ; The shell material is zirconium hydroxide. Among them, the particle size of the inner core is 9 μm, the thickness of the subshell layer is 6 μm, and the thickness of the outermost layer is 1000 nm. The diameter of the micropores in the shell layer is 0.5 μm.

[0083] The method for preparing the core-double shell structure composite nickel-cobalt-manganese ternary precursor material is as follows:

[0084] (1) The core material is a lithium-rich manganese-based nickel-cobalt-manganese ternary cathode material pr...

Embodiment 3

[0093] The core-double-shell structure composite nickel-cobalt-manganese ternary precursor material includes a core, a subshell layer and an outermost layer, the subshell layer is coated on the outer surface of the core, and the outermost layer is coated on the outer surface of the subshell layer , where: the chemical formula of the core material is Ni 0.15 co 0.15 mn 0.70 CO 3 ; The chemical formula of the subshell material is Ni 0.50 co 0.20 mn 0.30 (OH) 2 ; The shell material is titanium hydroxide. Among them, the particle size of the inner core is 1 μm, the thickness of the subshell layer is 1 μm, and the thickness of the outermost layer is 5 nm. The diameter of the micropores in the shell layer is 0.1 μm.

[0094] The method for preparing the core-double shell structure composite nickel-cobalt-manganese ternary precursor material is as follows:

[0095] (1) The core material is a lithium-rich manganese-based nickel-cobalt-manganese ternary cathode material precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com