Mutton fat jade ceramic tile and preparation method thereof

A technology of suet jade and ceramic tiles, which is applied in the field of ceramic brick production and manufacturing, can solve the problems of long firing time, high firing temperature of suet jade porcelain, limited storage of raw materials, etc., and achieve the purpose of inhibiting phase separation and crystallization, The effect of increasing light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the sheep fat jade ceramic brick is illustrated as follows.

[0025] Prepare suet jade body. The mineral composition of the suet jade body includes: by mass percentage, translucent potassium feldspar: 42.0-50.0%, acicular translucent kaolin: 37.0-43.0%, and fused silica sand: 7.0-21.0%. As an example, the mineral composition of the suet jade body is: by mass percentage, translucent potassium feldspar: 46%, acicular translucent kaolin: 40%, and fused silica sand: 14%.

[0026] Translucent potassium feldspar is a mineral raw material mainly composed of potassium feldspar, containing a small amount of albite and free quartz. After being processed and purified by magnetic separation whitening equipment, the content of iron and titanium impurities in translucent potassium feldspar is reduced When it is less than 0.06 wt%, the purity of the translucent potassium feldspar can be improved, and the transmittance of the translucent potassium feldspar ca...

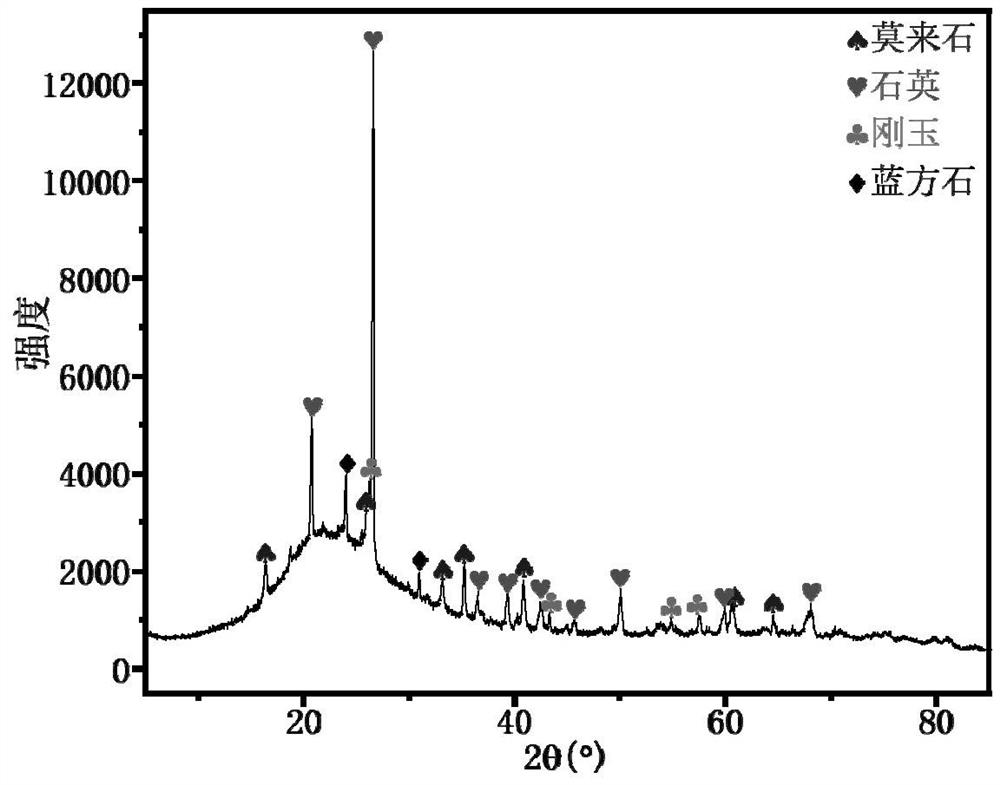

Embodiment 1

[0048] Step 1: Weigh the raw materials according to the mineral composition of the sheep fat jade body, and prepare the green body powder. The mineral composition of the suet jade body includes: by mass percentage, translucent potassium feldspar: 46%, acicular translucent kaolin: 40%, and fused silica: 14%. The chemical composition of the suet jade body includes: by mass percentage, SiO 2 : 64.09%, Al 2 o 3 : 22.38%, Fe 2 o 3 : 0.12%, TiO 2 : 0.05%, CaO: 0.51%, MgO: 0.16%, K 2 O: 4.62%, Na 2 O: 2.36%, loss on ignition: 5.57%.

[0049] Step 2: pressing the green body powder into a green body, and drying the green body. The drying time is 15-30 minutes, and the moisture content of the dried blank is controlled within 0.5 wt%.

[0050] Step 3: After the suet jade body is dried at high temperature, print the design pattern with an inkjet machine.

[0051] Step 4: Prepare suet jade protective glaze. The mineral composition of the suet jade protective glaze includes: by m...

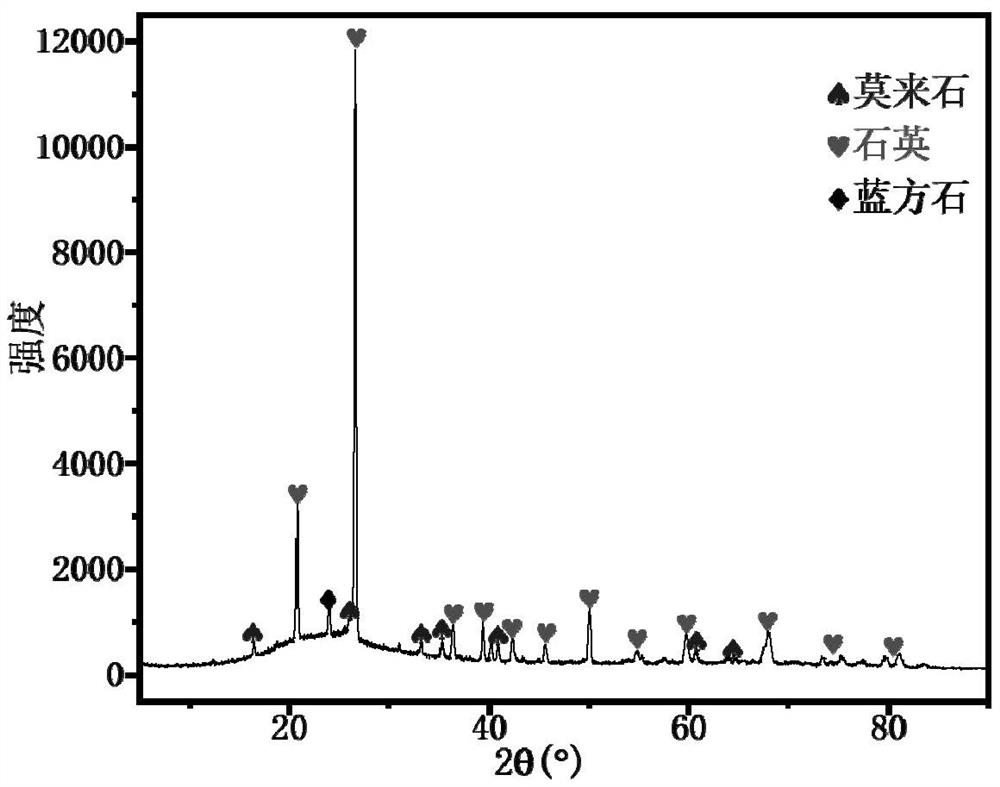

Embodiment 2

[0057] Step 1: Weigh the raw materials according to the mineral composition of the sheep fat jade body, and prepare the green body powder. The mineral composition of the suet jade body includes: by mass percentage, 50% of translucent potassium feldspar, 43% of acicular translucent kaolin, and 7% of fused quartz. The chemical composition of the suet jade body includes: by mass percentage, SiO 2 : 61.29%, Al 2 o 3 : 24.13%, Fe 2 o 3 : 0.13%, TiO 2 : 0.05%, CaO: 0.56%, MgO: 0.17%, K 2 O: 5.10%, Na 2 O: 2.48%, loss on ignition: 5.96%.

[0058] Step 2: pressing the green body powder into a green body, and drying the green body. The drying time is 15-30 minutes, and the moisture content of the dried blank is controlled within 0.5 wt%.

[0059] Step 3: After the suet jade body is dried at high temperature, print the design pattern with an inkjet machine.

[0060] Step 4: Prepare suet jade protective glaze. The mineral composition of the suet jade protective glaze includes:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com