Preparation methods of benzocyclobutene functionalized cage type polysilsesquioxane (POSS) and resins of benzocyclobutene functionalized cage type polysilsesquioxane

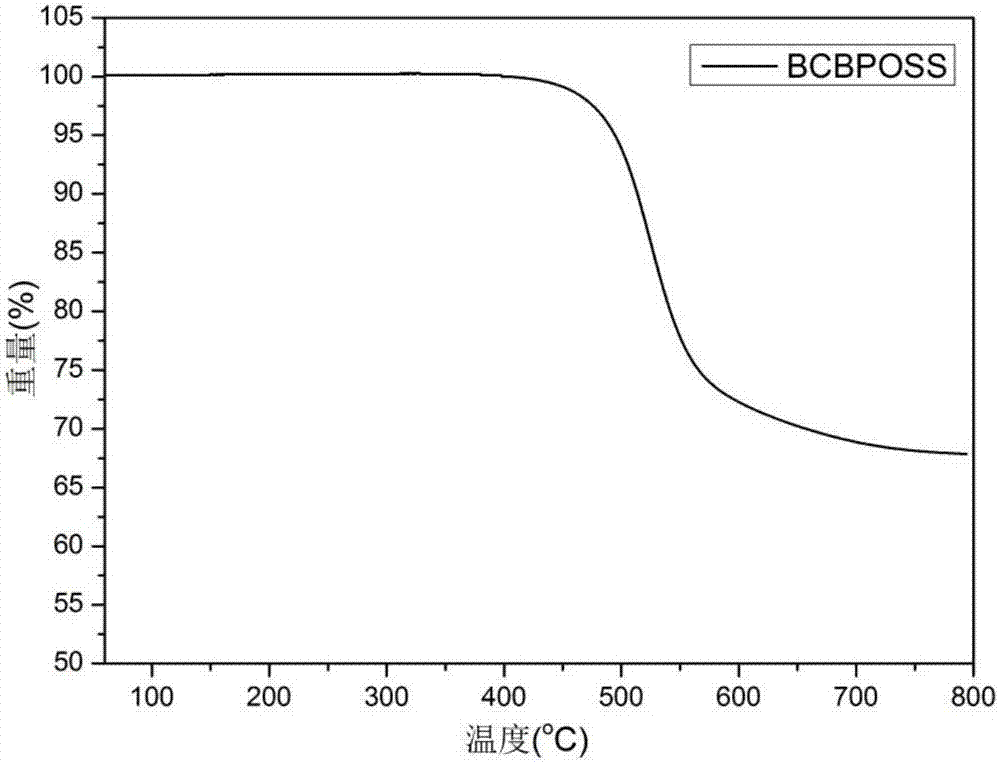

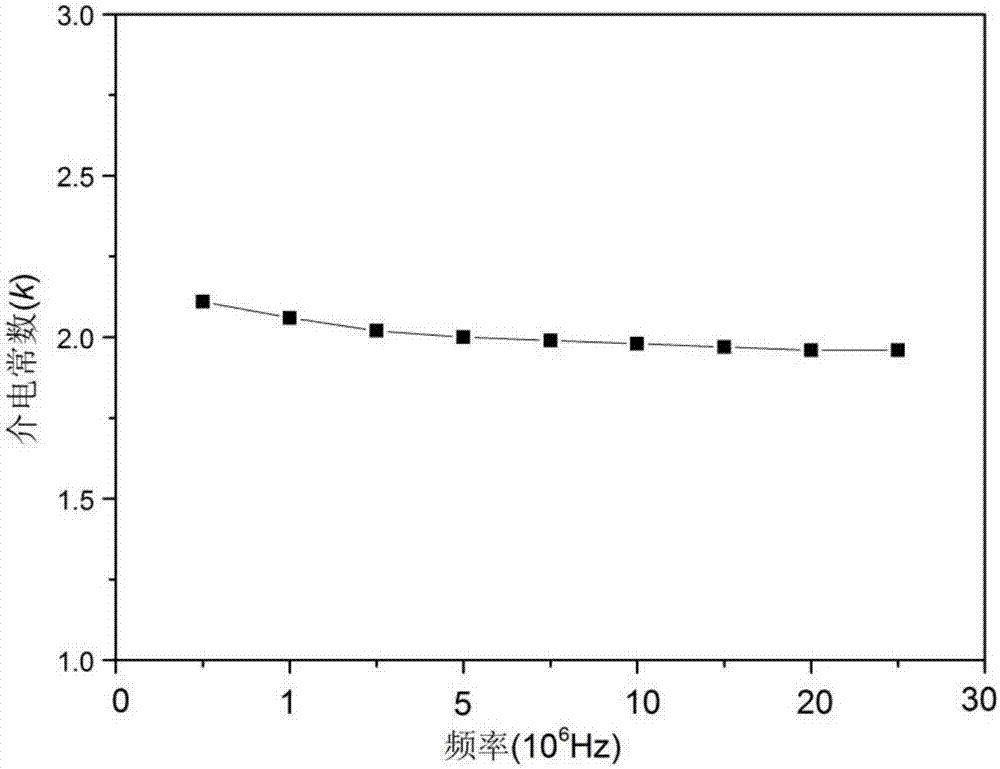

A benzocyclobutene functional, polysilsesquioxane technology, applied in the direction of coating, can solve problems such as limiting the application of materials, and achieve the effects of low dielectric properties, excellent heat resistance, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

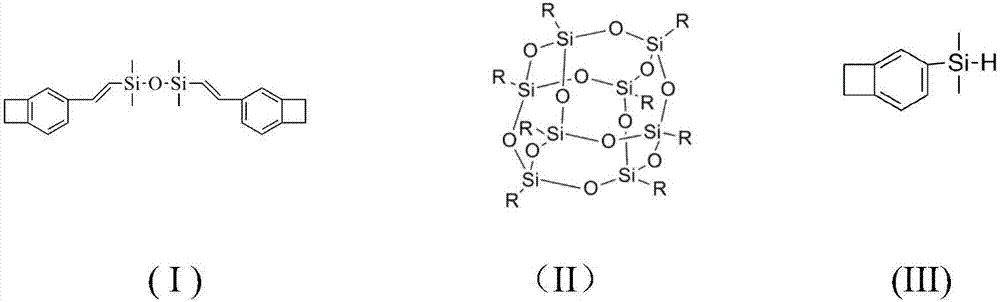

[0051] Benzocyclobutene functionalized cage polysilsesquioxane is characterized in that the compound has the chemical structural formula shown in (IV):

[0052]

[0053] In the formula:

[0054]

[0055] 01 1 =8.

Embodiment 2

[0057] The preparation method of cage type [1,1-dimethyl, 1-(4'-benzocyclobutenyl) silicon ethyl] vinyl silsesquioxane (BCB-POSS for short), the steps are: drying In an anaerobic bottle equipped with a magnetic stirrer, add 6.33 g of cage-type octavinylsilsesquioxane (OVPOSS for short), pass nitrogen gas for 10 minutes to remove the oxygen in the system, and then add [4-(1,1- Dimethyl-1-hydrogen)] silylbenzocyclobutene (abbreviated as 4-DMHSBCB) 16.2g, molar concentration is 0.025M (catalyst) H 2 PtCl 6 100 μL of tetrahydrofuran solution and 50 mL of toluene, the mixture was reacted at 80° C. for 72 hours under a nitrogen atmosphere, and the reaction raw material OVPOSS was monitored by thin-layer chromatography to see if the reaction was complete. After the reaction is over, cool the reacted material to room temperature, add ethanol with 5 times the mass of the reacted material, precipitate, and filter; add ethanol with 5 times the mass of the reacted material to the solid o...

Embodiment 3

[0060] The preparation method of cage type [1,1-dimethyl, 1-(4'-benzocyclobutenyl) silicon ethyl] vinyl silsesquioxane (BCB-POSS for short), the steps are: drying In an anaerobic bottle equipped with a magnetic stirrer, add 6.33 g of cage-type octavinylsilsesquioxane (OVPOSS for short), pass nitrogen gas for 30 minutes to remove the oxygen in the system, and then add [4-(1,1- Dimethyl-1-hydrogen)] silylbenzocyclobutene (abbreviated as 4-DMHSBCB) 24.3g, molar concentration is 0.025M (catalyst) H 2 PtCl 6 200 μL of tetrahydrofuran solution and 60 mL of toluene, the mixture was reacted at 85° C. for 60 hours under a nitrogen atmosphere, and the reaction raw material OVPOSS was monitored by thin-layer chromatography to see if the reaction was complete. After the reaction, cool the reacted material to room temperature, add ethanol with 10 times the mass of the reacted material, precipitate, and filter; add ethanol with 10 times the mass of the reacted material to the solid obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com