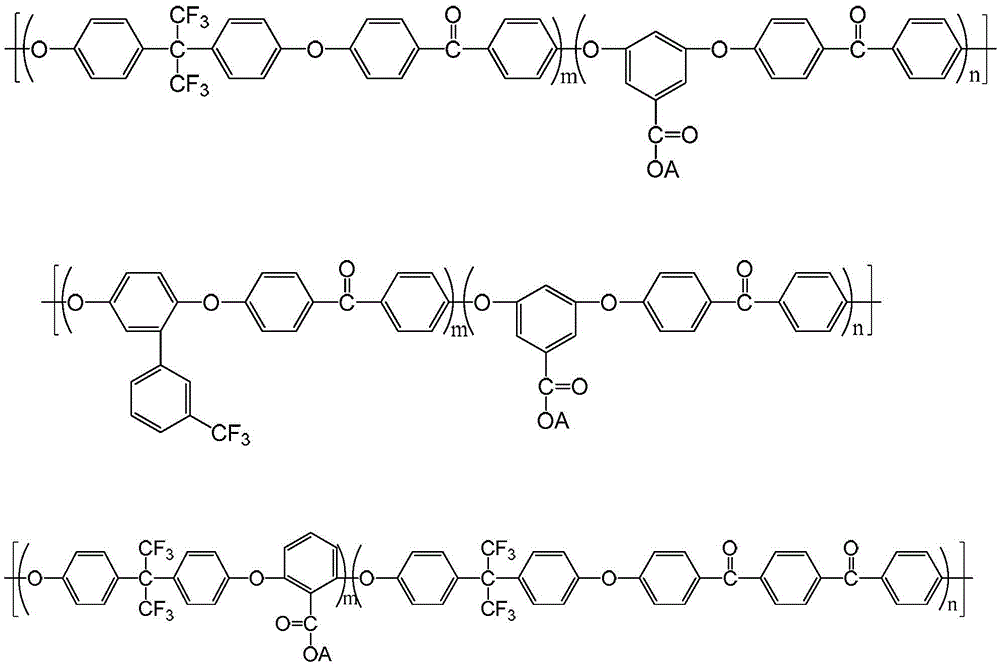

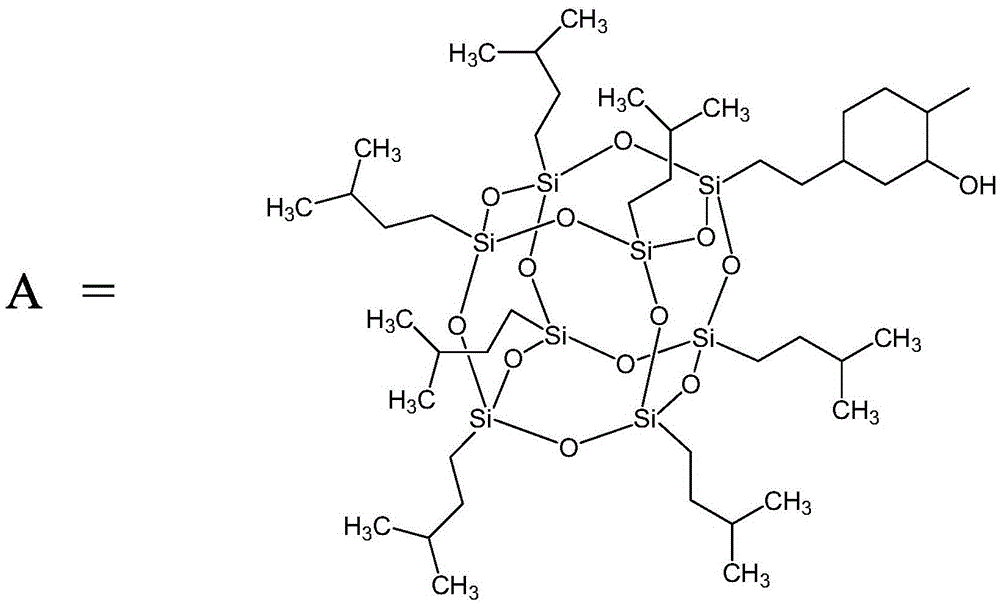

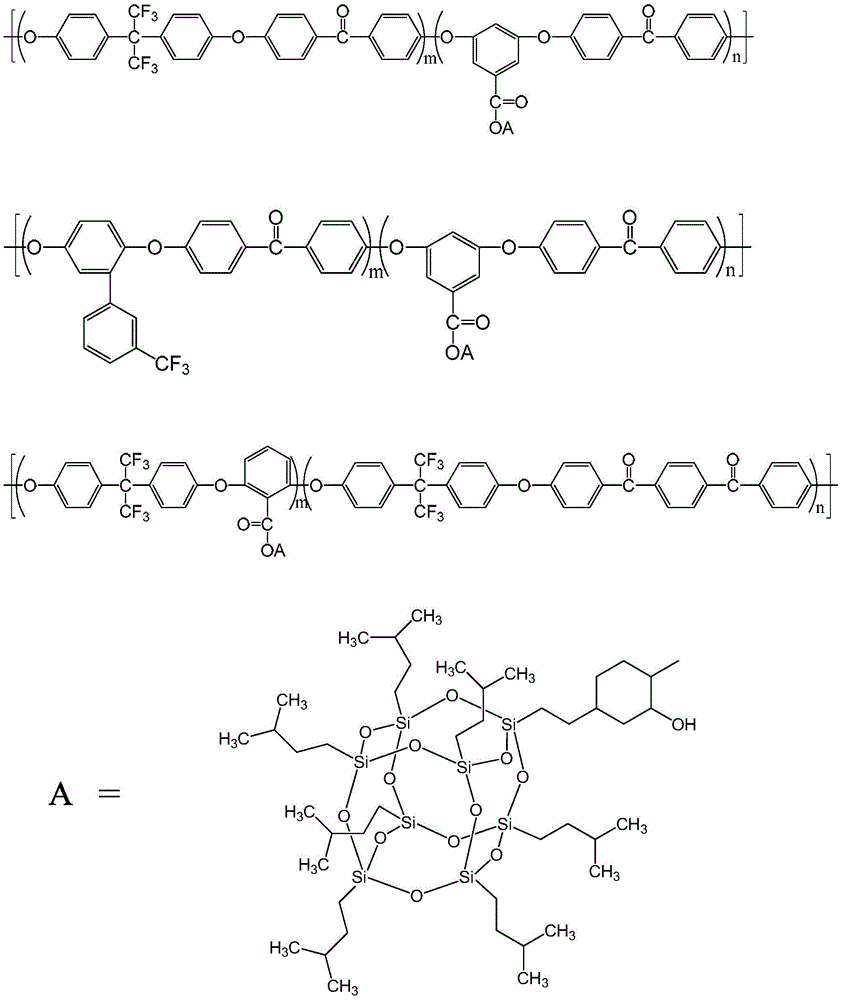

PEAK (polyaryletherketone) polymer with POSS (polysilsesquioxane) structure and preparation method

A technology of polysilsesquioxane and polyaryletherketone, which is applied in the field of preparation of polyaryletherketone series polymers containing POSS structure, can solve the problems of poor film-forming properties and low mechanical properties, and achieve improved heat resistance, The effect of lowering the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 65.46g (0.300mol) 4,4'-difluorobenzophenone, 95.826g (0.285mol) hexafluorobisphenol A, 2.312g (0.015 mol) 3,5-dihydroxybenzoic acid, 44.000g (0.315mol) potassium carbonate, 360ml sulfolane (using sulfolane as a solvent, the solvent addition is advisable with a solid content of 20% to 35%, and the amount of sulfolane in this embodiment is based on the solid content Quantity 25% calculation), 100ml toluene. Under stirring conditions, the temperature was raised to 140°C for 3 hours. After the water generated by the reaction was completely taken out, the temperature was continued to release toluene, and then the temperature was raised to 180°C for 3 hours, and finally the temperature was raised to 220°C for 5 hours. The reaction product is discharged in 5% hydrochloric acid solution. After cooling, the product was pulverized, washed with deionized water and ethanol for 5 times to remove inorganic salts and organic solvents, and finally the product was vacuum-dried at 1...

Embodiment 2

[0022] The method is as in Example 1, changing the molar content of 3,5-dihydroxybenzoic acid to 30%, namely [3,5-dihydroxybenzoic acid / (3,5-dihydroxybenzoic acid+hexafluorobisphenol A)] The molar ratio is 30%. After acid chlorination, 0.09108 g of POSS was added, and the reaction was continued as in Example 1 to obtain a white polyaryletherketone polymer containing hexafluorobisphenol A structure with a POSS content of 30%, with a yield of 97%.

Embodiment 3

[0024] The method is as in Example 1, changing the molar content of 3,5-dihydroxybenzoic acid to 17.5%, namely [3,5-dihydroxybenzoic acid / (3,5-dihydroxybenzoic acid+hexafluorobisphenol A)] The molar ratio is 17.5%. After acid chlorination, 0.05313 g of POSS was added, and the reaction was continued as in Example 1 to obtain white polyaryletherketone polymers containing hexafluorobisphenol A structure with a POSS content of 17.5%, with a yield of 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com