Degradable plastic mulching film based on PBAT and preparation method of degradable plastic mulching film

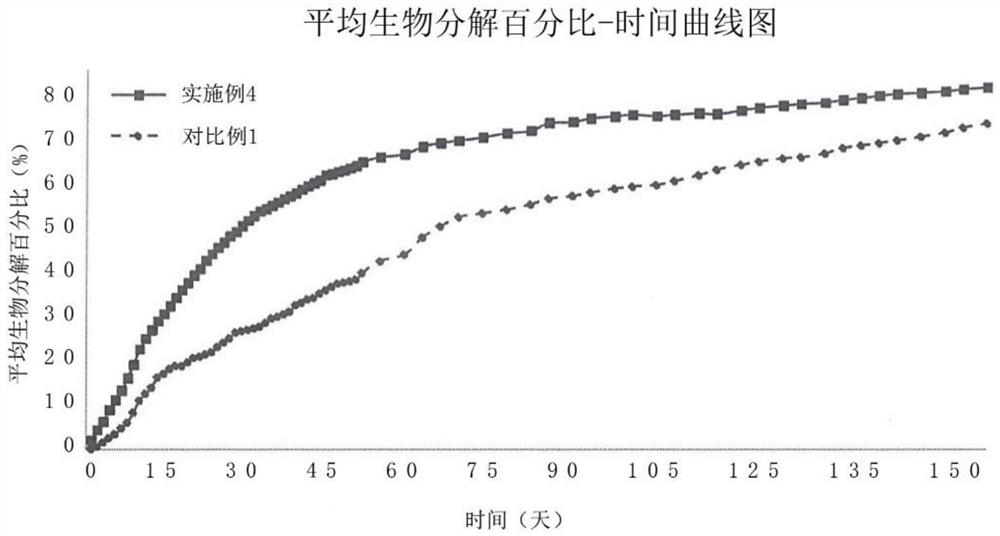

A technology for degrading plastics and mulches, applied in the field of plastics, can solve the problems of excessive rigidity, unsatisfactory degradable performance, uneven mechanical properties, etc., and achieve the effect of increasing degradability, stable and uniform mechanical properties and degradable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

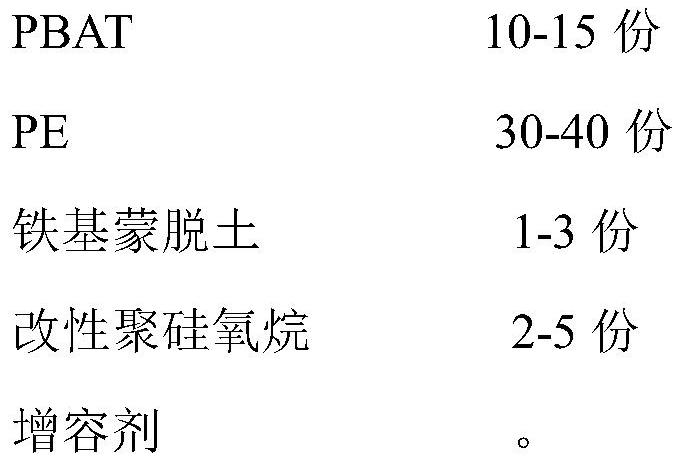

[0044] A kind of degradable plastic mulching film based on PBAT, it comprises the composition of following mass parts:

[0045]

[0046] The preparation method of the above-mentioned degradable plastic film based on PBAT is:

[0047] S1. Preparation of modified polysiloxane: dissolve 1mmol of hydrogen-containing silicone oil (0.18wt% hydrogen content) and 1.2mmol of polyethylene glycol monomethyl ether in 100ml of xylene, add 0.15 wt% zinc acetate containing hydrogen silicone oil was used as a catalyst, and under the protection of argon, it was heated to reflux for 10 h to obtain a crude product. Then the solvent in the system was distilled off under reduced pressure, and the concentrate was passed through a silica gel column (mobile phase: petroleum ether: dichloromethane = 2:1, v / v), and the product was collected to obtain a modified polysiloxane.

[0048] S2. Blend PBAT and PE according to the above-mentioned parts by mass, add them to the planetary ball mill, and ball ...

Embodiment 2

[0051] A kind of degradable plastic mulching film based on PBAT, it comprises the composition of following mass parts:

[0052]

[0053] The preparation method of the above-mentioned degradable plastic film based on PBAT is:

[0054] S1. Preparation of modified polysiloxane: Dissolve 1mmol of hydrogen-containing silicone oil (0.36wt% hydrogen content) and 1.6mmol of polypropylene glycol monomethyl ether in 100ml of xylene, but add hydrogen-containing 0.25wt% zinc acetate in silicone oil was used as a catalyst, and under the protection of argon, it was heated to reflux for 10 h to obtain a crude product. Then the solvent in the system was distilled off under reduced pressure, and the concentrate was passed through a silica gel column (mobile phase: petroleum ether: dichloromethane = 2:1, v / v), and the product was collected to obtain a modified polysiloxane.

[0055] S2. Blend PBAT and PE according to the above-mentioned parts by mass, add them to the planetary ball mill, an...

Embodiment 3

[0058] A kind of degradable plastic mulching film based on PBAT, it comprises the composition of following mass parts:

[0059]

[0060] The preparation method of the above-mentioned degradable plastic film based on PBAT is:

[0061] S1. Preparation of modified polysiloxane: Dissolve 1mmol of hydrogen-containing silicone oil (0.18wt% hydrogen content) and 1.3mmol of polypropylene glycol monomethyl ether in 100ml of xylene, but add hydrogen-containing 0.20wt% zinc acetate in silicone oil was used as a catalyst, and under the protection of argon, it was heated to reflux for 8 hours to obtain a crude product. Then the solvent in the system was distilled off under reduced pressure, and the concentrate was passed through a silica gel column (mobile phase: petroleum ether: dichloromethane = 2:1, v / v), and the product was collected to obtain a modified polysiloxane.

[0062] S2. Blend PBAT and PE according to the above-mentioned parts by mass, add them to the planetary ball mill,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com