Wear-resistant SBS modified asphalt and preparation method thereof

A modified asphalt and modified technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of lack of wear resistance, high molecular weight, low density, etc., and achieve greater sliding difficulty, higher molecular weight and density, The effect of increasing polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

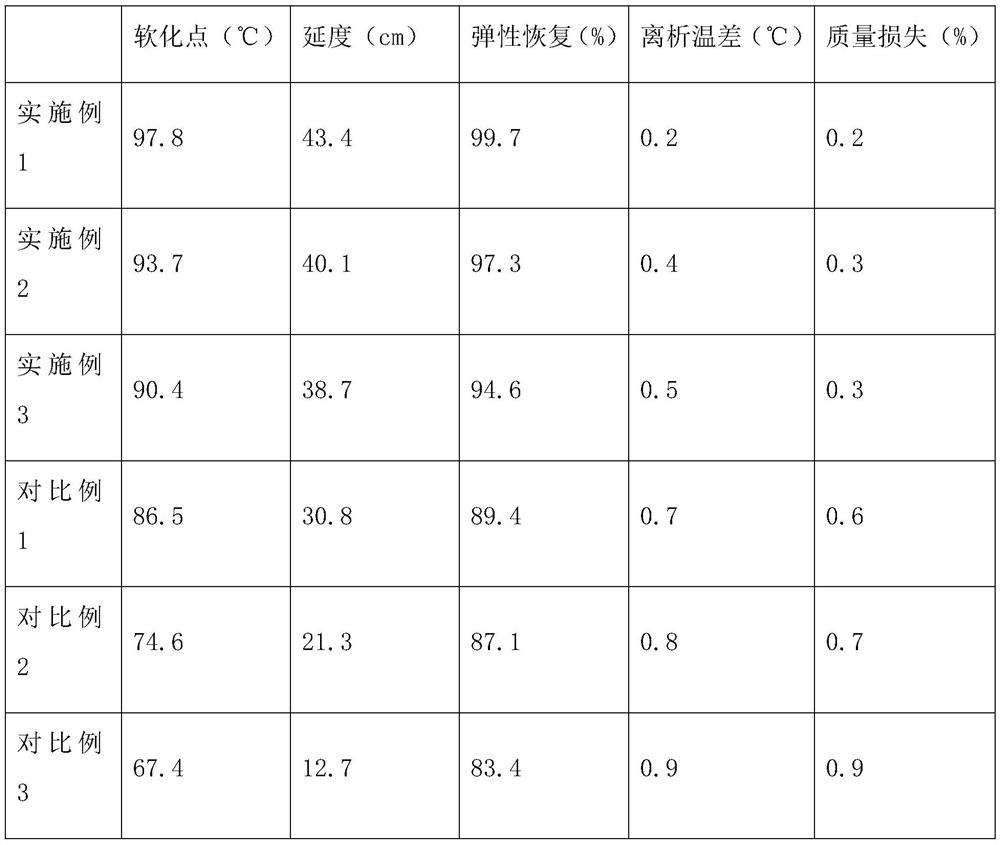

Examples

Embodiment 1

[0039] (1) Preparation of modified SBS:

[0040] Mix vinyl chloride and vinyl acetate, add photoinitiator 1-hydroxycyclohexyl phenylhexanone, in nitrogen atmosphere, use 150μW / cm 2The light intensity of ultraviolet light was irradiated for 40 minutes; the reaction product was pulverized, soaked in acetone for 48 hours, stirred and dissolved, added deionized water, and the precipitate was dried at 80°C for 48 hours to obtain product A; among them, vinyl chloride and vinyl acetate The mass ratio is 4.2:1.0, and the concentration of the photoinitiator in the reaction system is 3×10 -3 mol / L;

[0041] Take the product A, add methanol, heat to dissolve, adjust the temperature of the system to 40°C, add sodium hydroxide solution and methanol, stir for 30 minutes, add sodium hydroxide solution and methanol, increase the stirring speed, and continue stirring for 75 minutes; take the solid product for washing, Dry at 80°C for 12 hours to obtain product B;

[0042] Dissolve SBS and p...

Embodiment 2

[0050] (1) Preparation of modified SBS:

[0051] Mix vinyl chloride and vinyl acetate, add photoinitiator 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, in nitrogen atmosphere, at 20μW / cm 2 The light intensity of ultraviolet light was irradiated for 60 minutes; the reaction product was crushed, soaked in acetone for 45 hours, stirred and dissolved, added deionized water, and the precipitate was dried at 75°C for 45 hours to obtain product A; among them, vinyl chloride and vinyl acetate The mass ratio is 1.0:1.8), and the concentration of the photoinitiator in the reaction system is 1×10 -5 mol / L;

[0052] Take the product A, add methanol, heat to dissolve, adjust the temperature of the system to 35°C, add sodium hydroxide solution and methanol, stir and react for 20 minutes, add sodium hydroxide solution and methanol, increase the stirring speed, and continue stirring for 60 minutes; take the solid product for washing, Dry at 75°C for 10 hours to obtain prod...

Embodiment 3

[0061] (1) Preparation of modified SBS:

[0062] Mix vinyl chloride and vinyl acetate, add photoinitiator azobisisoheptanonitrile, in nitrogen atmosphere, use 300μW / cm 2 The light intensity of ultraviolet light was irradiated for 20 minutes; the reaction product was crushed, soaked in acetone for 54 hours, stirred and dissolved, added deionized water, and the precipitate was dried at 85 ° C for 50 hours to obtain product A; among them, vinyl chloride and vinyl acetate The mass ratio is 2.6:1.4, and the concentration of the photoinitiator in the reaction system is 5×10 -3 mol / L;

[0063] Take the product A, add methanol, heat to dissolve, adjust the temperature of the system to 45°C, add sodium hydroxide solution and methanol, stir for 40 minutes, add sodium hydroxide solution and methanol, increase the stirring speed, and continue stirring for 90 minutes; take the solid product for washing, Dry at 85°C for 15 hours to obtain product B;

[0064] Dissolve SBS and product B in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com