Antibacterial hydrophobic dendritic polyacrylate emulsion and preparation method thereof

A technology of polyacrylate emulsion and dodecafluoroheptyl acrylate is applied in the field of antibacterial and hydrophobic dendritic polyacrylate emulsion and its preparation, and achieves the effects of improving crosslinking density, improving structural stability and anti-light aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

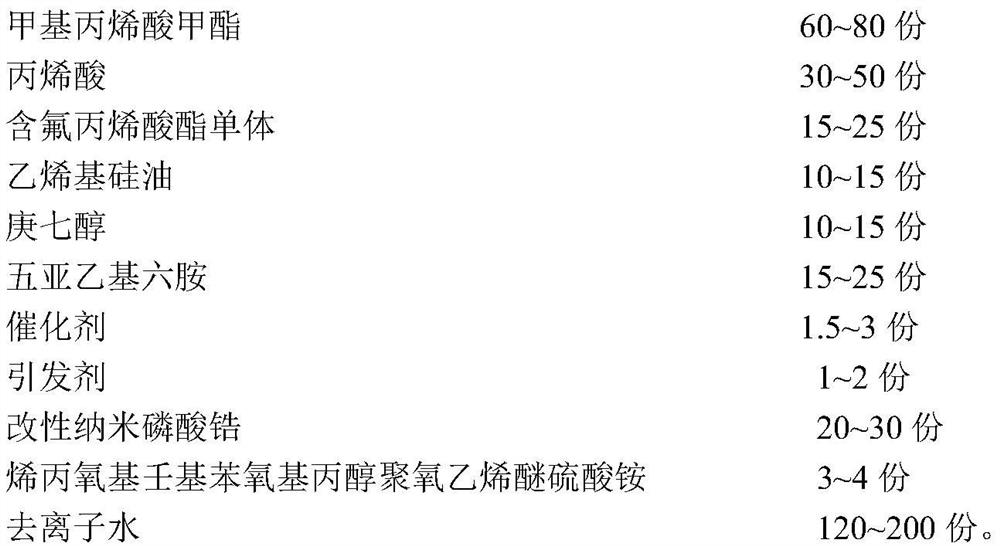

[0031] An antibacterial hydrophobic dendritic polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0032]

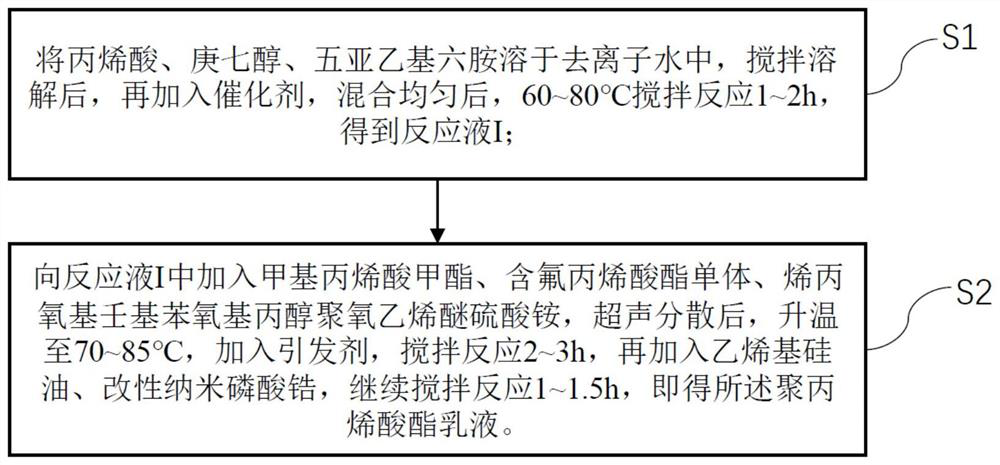

[0033] A preparation method for antibacterial hydrophobic dendritic polyacrylate emulsion, comprising the following steps:

[0034] S1: Catalyst preparation: DMAP, HOAT, and polyaniline doped with p-toluenesulfonic acid were uniformly mixed at a mass ratio of 1:0.6:1.5 to obtain a catalyst;

[0035] S2: Preparation of modified nano zirconium phosphate:

[0036] i: Ag + / Zn 2+ Modification: immerse nano zirconium phosphate in 0.02mol / L AgNO 3 and 0.01mol / L Zn(NO 3 ) 2 In the mixed solution, control the solid-liquid ratio to 1g / 10mL, sonicate for 0.5h, filter, and vacuum-dry to obtain Ag + / Zn 2+ Modified nano zirconium phosphate;

[0037] ii: intercalation modification: the Ag + / Zn 2+ Add the modified nano-zirconium phosphate to the aqueous solution with a mass fraction of 5% dodecylguanidine acetate, control the solid-liquid rat...

Embodiment 2

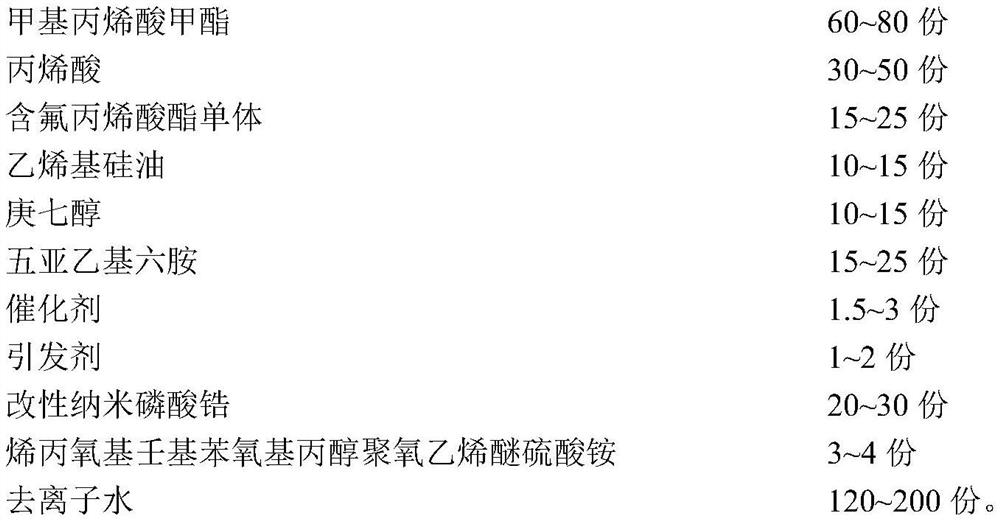

[0042] An antibacterial hydrophobic dendritic polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0043]

[0044] A preparation method for antibacterial hydrophobic dendritic polyacrylate emulsion, comprising the following steps:

[0045] S1: Preparation of catalyst: DMAP, HOAT, and p-aminobenzenesulfonic acid-doped polyaniline were uniformly mixed at a mass ratio of 1:0.8:1.75 to obtain a catalyst;

[0046] S2: Preparation of modified nano zirconium phosphate:

[0047] i: Ag + / Zn 2+ Modification: immerse nano zirconium phosphate in 0.06mol / L AgNO 3 and 0.03mol / L Zn(NO 3 ) 2 In the mixed solution of , control the solid-liquid ratio to 1g / 12.5mL, ultrasonically treat for 1h, filter, and vacuum-dry to obtain Ag + / Zn 2+ Modified nano zirconium phosphate;

[0048] ii: intercalation modification: the Ag + / Zn 2+ Add the modified nano-zirconium phosphate to the aqueous solution with a mass fraction of 7.5% polyhexamethylene biguanide, con...

Embodiment 3

[0053] An antibacterial hydrophobic dendritic polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0054]

[0055]

[0056] A preparation method for antibacterial hydrophobic dendritic polyacrylate emulsion, comprising the following steps:

[0057] S1: Catalyst preparation: DMAP, HOAT, and phosphotungstic acid doped polyaniline were evenly mixed at a mass ratio of 1:1:2 to obtain a catalyst;

[0058] S2: Preparation of modified nano zirconium phosphate:

[0059] i: Ag + / Zn 2+ Modification: immerse nano zirconium phosphate in 0.1mol / L AgNO 3 and 0.05mol / L Zn(NO 3 ) 2 In the mixed solution, control the solid-liquid ratio to 1g / 15mL, ultrasonically treat for 2h, filter, and vacuum-dry to obtain Ag + / Zn 2+ Modified nano zirconium phosphate;

[0060] ii: intercalation modification: the Ag + / Zn 2+ Add the modified nano-zirconium phosphate to an aqueous solution with a mass fraction of 10% polyhexamethylene biguanide hydrochloride, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com