Glass and method for producing same

A manufacturing method and glass technology, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve problems such as brightness not reaching a practical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0194] Hereinafter, the present invention (first present invention) will be described in detail based on examples. It should be noted that the following examples are merely examples. The present invention (first present invention) is not limited at all by the following examples.

[0195] Tables 1 and 2 show sample Nos. 1 to 20.

[0196] 【Table 1】

[0197] (wt%)

No.1

No.2

No.3

No.4

No.5

No.6

No.7

No.8

No.9

No.10

SiO 2

55.0

47.0

39.0

39.0

47.0

47.0

43.0

39.0

39.0

55.0

al 2 o 3

15.0

15.0

15.0

10.0

15.0

15.0

15.0

15.0

23.0

7.0

B 2 o 3

22.0

22.0

22.0

22.0

22.0

22.0

22.0

22.0

22.0

22.0

MgO

6.4

6.4

6.4

6.4

6.4

6.4

6.4

6.4

6.4

6.4

CaO

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

SrO

-

...

Embodiment 2

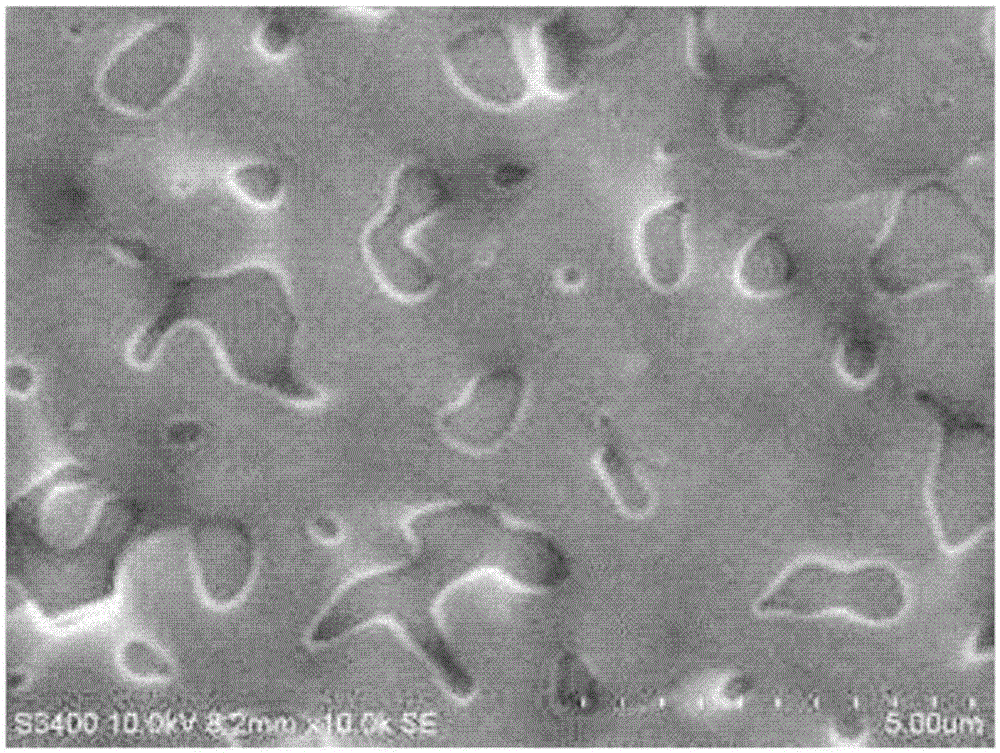

[0213] Sample Nos. 2 and 9 to 20 not subjected to the above-mentioned heat treatment were immersed in a 1 M hydrochloric acid solution for 10 minutes, and then the surface of the sample was observed with a scanning electron microscope (S-4300SE manufactured by Hitachi High-Tech Co., Ltd.). The results are shown in the Figure 1-13 . Figure 1-13 Scanning electron microscope images of the surfaces of sample Nos. 2 and 9 to 20 are shown, respectively. As a result, samples No.2, 9, 10, 12-20 have a phase-separated structure and are rich in B 2 o 3 phase (second phase: lack of SiO 2 layer) was dissolved by hydrochloric acid solution. It should be noted that richer than B 2 o 3 The phase is dissolved by hydrochloric acid solution, and rich in SiO 2 phase is insoluble in hydrochloric acid solution.

Embodiment 3

[0215] Samples Nos. 2, 12, and 19 that were not subjected to the above-mentioned heat treatment were processed so that the plate thickness became 1.0mm or 0.7mm, and both surfaces were mirror-polished, and the wavelengths in the table were measured by a spectrophotometer ( The total light transmittance and diffuse transmittance in the thickness direction were measured with a spectrophotometer UV-2500PC manufactured by Tsu Seisakusho. The results are shown in Tables 3-5.

[0216] 【table 3】

[0217]

[0218] 【Table 4】

[0219]

[0220] 【table 5】

[0221]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com