Antibacterial anti-aging flame-retardant dendritic polyacrylate emulsion and preparation method thereof

A technology of polyacrylate emulsion, dendritic, used in the field of polymer synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

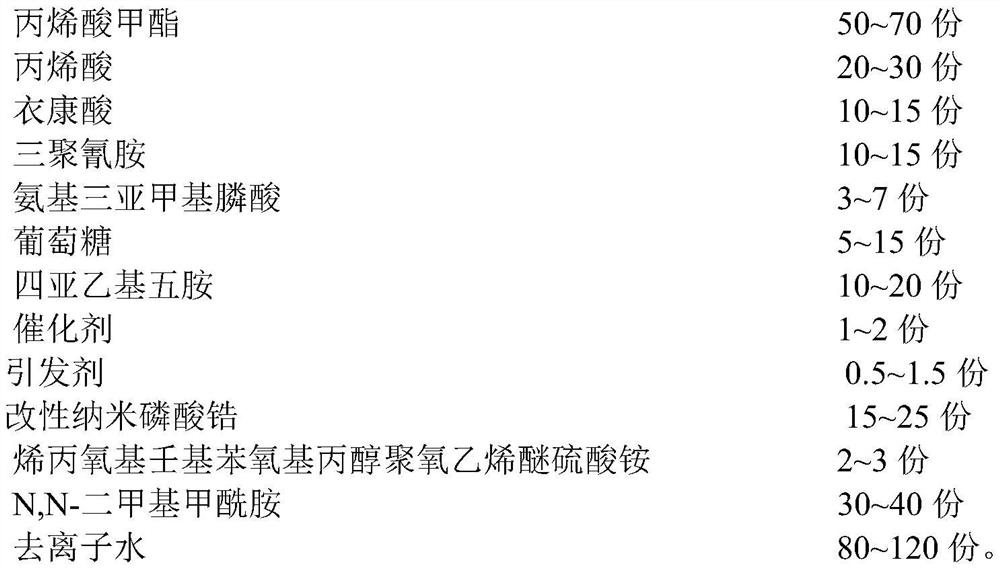

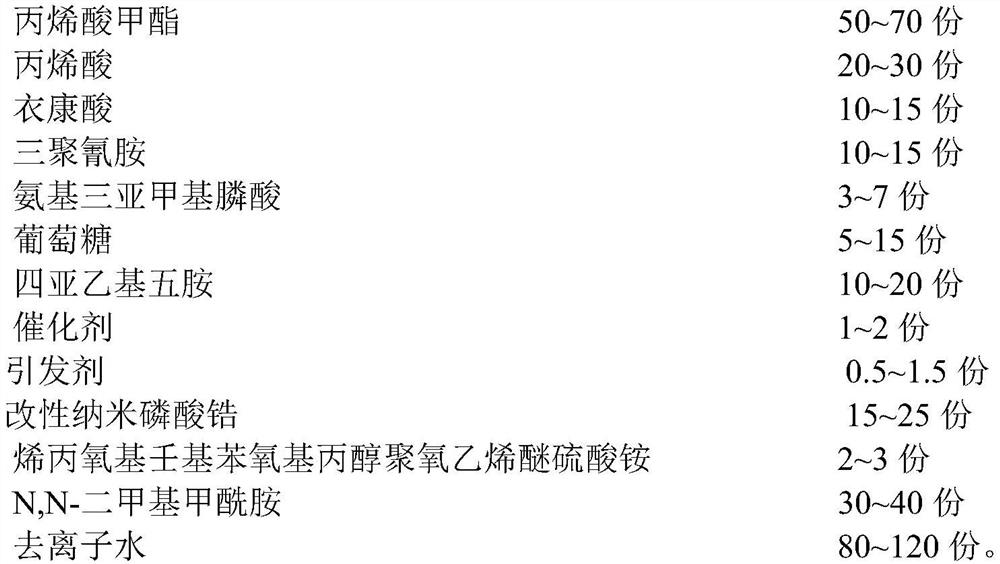

[0031] An antibacterial and anti-aging flame-retardant dendritic polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0032]

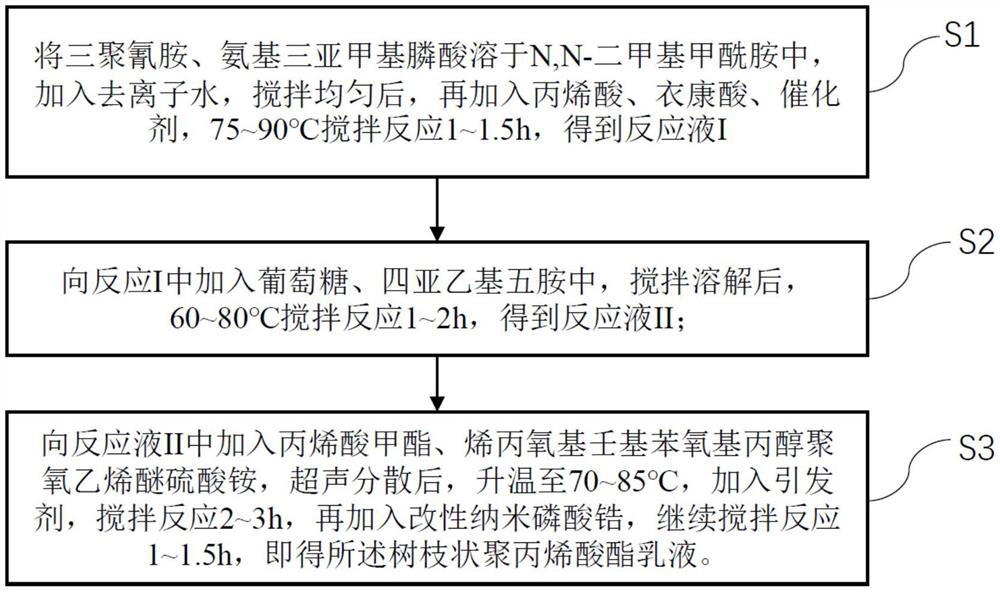

[0033] A kind of preparation method of antibacterial antiaging flame retardant type dendritic polyacrylate emulsion, comprises the following steps:

[0034] S1: Catalyst preparation: DMAP, HOAT, and p-toluenesulfonic acid-doped polyaniline were uniformly mixed at a mass ratio of 1:0.6:1.5 to obtain a catalyst;

[0035] S2: Preparation of modified nano zirconium phosphate:

[0036] i: Ag + / Zn 2+ Modification: immerse nano zirconium phosphate in 0.02mol / LAgNO 3 and 0.01mol / L Zn(NO 3 ) 2 In the mixed solution, control the solid-liquid ratio to 1g / 10mL, sonicate for 0.5h, filter, and vacuum-dry to obtain Ag + / Zn 2+ Modified nano zirconium phosphate;

[0037] ii: intercalation modification: the Ag + / Zn 2+ Add the modified nano-zirconium phosphate to the aqueous solution with a mass fraction of 5% dodecylguanidine...

Embodiment 2

[0043] An antibacterial and anti-aging flame-retardant dendritic polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0044]

[0045] A kind of preparation method of antibacterial antiaging flame retardant type dendritic polyacrylate emulsion, comprises the following steps:

[0046] S1: Catalyst preparation: DMAP, HOAT, and polyaniline doped with p-aminobenzenesulfonic acid were uniformly mixed at a mass ratio of 1:0.8:1.8 to obtain a catalyst;

[0047] S2: Preparation of modified nano zirconium phosphate:

[0048] i: Ag + / Zn 2+ Modification: immerse nano zirconium phosphate in 0.06mol / LAgNO 3 and 0.03mol / L Zn(NO 3 ) 2 In the mixed solution of , control the solid-liquid ratio to 1g / 12.5mL, ultrasonically treat for 1h, filter, and vacuum-dry to obtain Ag + / Zn 2+ Modified nano zirconium phosphate;

[0049] ii: intercalation modification: the Ag + / Zn 2+ Add the modified nano-zirconium phosphate to the aqueous solution with a mass fract...

Embodiment 3

[0055] An antibacterial and anti-aging flame-retardant dendritic polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0056]

[0057] A kind of preparation method of antibacterial antiaging flame retardant type dendritic polyacrylate emulsion, comprises the following steps:

[0058] S1: Preparation of catalyst: Mix DMAP, HOAT, and phosphotungstic acid doped polyaniline evenly at a mass ratio of 1:1:2 to obtain a catalyst;

[0059] S2: Preparation of modified nano zirconium phosphate:

[0060] i: Ag + / Zn 2+ Modification: immerse nano zirconium phosphate in 0.1mol / L AgNO 3 and 0.05mol / L Zn(NO 3 ) 2 In the mixed solution, control the solid-liquid ratio to 1g / 15mL, ultrasonically treat for 2h, filter, and vacuum-dry to obtain Ag + / Zn 2+ Modified nano zirconium phosphate;

[0061] ii: intercalation modification: the Ag + / Zn 2+ Add the modified nano-zirconium phosphate to an aqueous solution with a mass fraction of 10% polyaminopropyl big...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com