Hollow glass microspheres as well as preparation method and application thereof

A glass microsphere and hollow technology, which is applied to printed circuit parts, printed circuits, circuit substrate materials, etc., can solve the problems that cannot further meet the requirements of the dielectric constant performance of the circuit substrate, and achieve stable structure and low dielectric properties , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing hollow glass microspheres, comprising:

[0036] S1, by mass percentage, weigh 45%-80% of silicon dioxide, 5%-15% of alumina, 10%-35% of boron oxide, 0.1%-15% of calcium oxide, 0.1%-7 % magnesium oxide and 2%-10% titanium dioxide to form a mixed powder;

[0037] S2. In a non-polar gas atmosphere, after the mixed powder is expanded, heat-preserved and shaped, it is cooled and molded to obtain hollow glass microspheres.

[0038] In step S1, the mixed powder may also include a chemical foaming agent, and the mass percentage of the chemical foaming agent in the mixed powder is 0.1%-8%, so that chemical foaming or chemical foaming Combined with physical foaming, the volume of the body in the obtained hollow glass microspheres is 10%-35%.

[0039] Specifically, the chemical blowing agent includes at least one of carbonate compounds, nitrate compounds, and hydrazine. Wherein, the carbonate compound includes at least ...

Embodiment 1

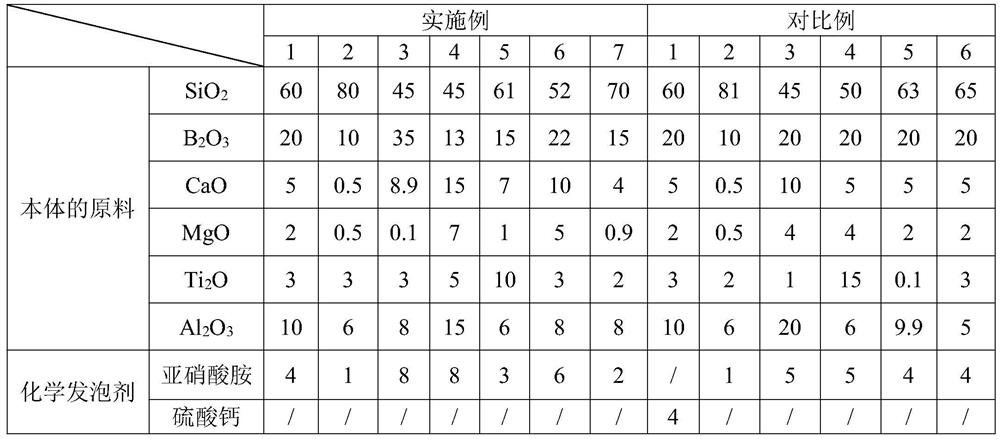

[0061] Weigh silicon dioxide, aluminum oxide, boron oxide, titanium oxide, calcium oxide, magnesium oxide and chemical blowing agent according to the mass ratio in Table 1, mix them, crush, grind, and sieve until the D50 is 10 μm-30 μm, and the D90 is 60 μm- 70 μm particle size to obtain mixed powder.

[0062] The mixed powder is heated to 500°C for drying, and then the dried mixed powder is transported into the expansion furnace through argon, so that the mixed powder is expanded at a high temperature of 1200°C, and kept at 900°C for setting, and then cooled molding to obtain hollow glass microspheres.

Embodiment 2-7

[0063] Embodiment 2-7 and comparative example 1-6

[0064] The manufacturing process is the same as in Example 1, and the proportioning ratio is changed as shown in Table 1.

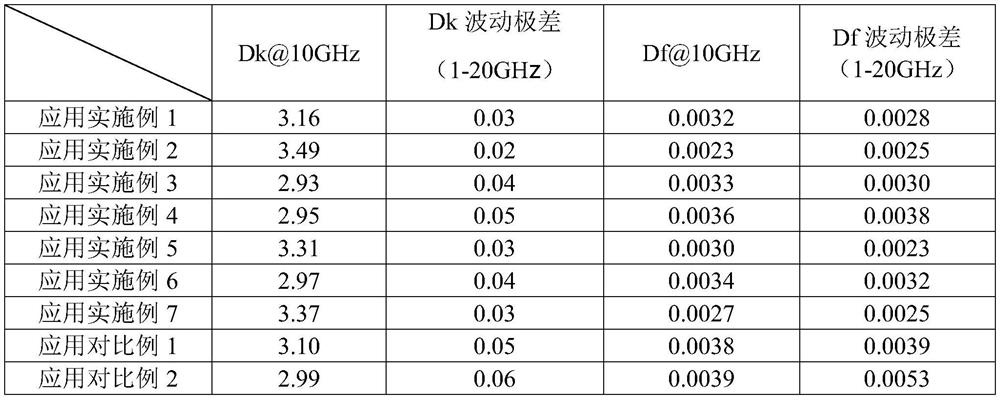

[0065] The hollow glass microspheres obtained in Examples 1-7 and Comparative Examples 1-6 were tested, and the results are shown in Table 2.

[0066] Table 2

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com