Bamboo charcoal composite fiber friction material and brake pad fabricated therefrom, and method for preparing same

A composite fiber and friction material technology, applied in the field of brake pads, can solve the problems of thermal degradation of brake pad braking performance, high wear rate, poor thermal degradation resistance, etc., and achieve good thermal degradation resistance, wide source of raw materials, accumulation The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

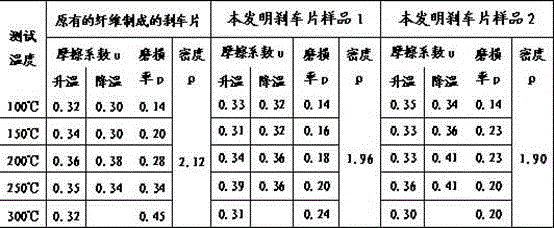

Examples

Embodiment 1

[0022] In this embodiment, the bamboo charcoal composite fiber friction material is composed of bamboo charcoal, organic plant fiber, coupling agent, and calcium carbonate whisker additive is added. The weight ratio of each component is: bamboo charcoal 65%, organic plant fiber 20%, silane coupling Agent 7%, calcium carbonate whisker additive 8%.

[0023] The brake pad made of the above-mentioned bamboo-charcoal composite fiber friction material is composed of bamboo-charcoal composite fiber friction material, mineral fiber, resin, barite powder, nitrile rubber, alumina, graphite, glass fiber, steel wool, tire powder, each component The weight ratio is: bamboo charcoal composite fiber friction material 20%, mineral fiber 10%, resin 12%, barite powder 18%, nitrile rubber 4%, alumina 4%, graphite 15%, glass fiber 5%, steel wool 8%, tire powder 4%.

Embodiment 2

[0025] In this embodiment, the bamboo charcoal composite fiber friction material is composed of bamboo charcoal, organic plant fiber, coupling agent, and calcium carbonate whisker additive is added. The weight ratio of each component is: bamboo charcoal 70%, organic plant fiber 15%, silane coupling Additive 5%, calcium carbonate whisker additive 10%.

[0026] The brake pad made of the above-mentioned bamboo-charcoal composite fiber friction material is composed of bamboo-charcoal composite fiber friction material, mineral fiber, resin, barite powder, nitrile rubber, alumina, graphite, glass fiber, steel wool, tire powder, each component The weight ratio is: bamboo charcoal composite fiber friction material 25%, mineral fiber 15%, resin 15%, barite powder 24%, nitrile rubber 2%, alumina 2%, graphite 10%, glass fiber 2%, steel wool 3%, tire powder 2%.

Embodiment 3

[0028] In this embodiment, the bamboo charcoal composite fiber friction material is composed of bamboo charcoal, organic plant fiber, coupling agent, and calcium carbonate whisker additive is added. The weight ratio of each component is: bamboo charcoal 60%, organic plant fiber 25%, silane coupling Agent 10%, calcium carbonate whisker additive 5%.

[0029] The brake pad made of the above-mentioned bamboo-charcoal composite fiber friction material is composed of bamboo-charcoal composite fiber friction material, mineral fiber, resin, barite powder, nitrile rubber, alumina, graphite, glass fiber, steel wool, tire powder, each component The weight ratio is: bamboo charcoal composite fiber friction material 15%, mineral fiber 5%, resin 8%, barite powder 12%, nitrile rubber 6%, alumina 6%, graphite 20%, glass fiber 8%, steel wool 12%, tire powder 8%.

[0030] The method for making the above-mentioned brake pads, the specific steps are as follows:

[0031] 1) First make bamboo cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thermal stability temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com