Yaw brake pad made of various materials

A brake pad and yaw technology, applied in the field of wind turbine braking system, can solve the problems of limited brake pad function, low heat resistance and wear resistance, and reduced braking efficiency, so as to increase the friction coefficient and wear resistance. , The effect of increasing hardness and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

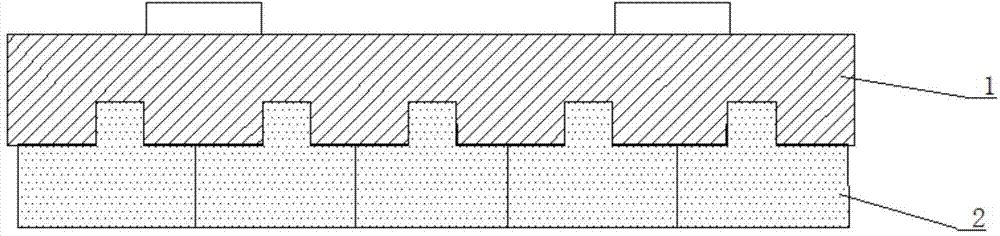

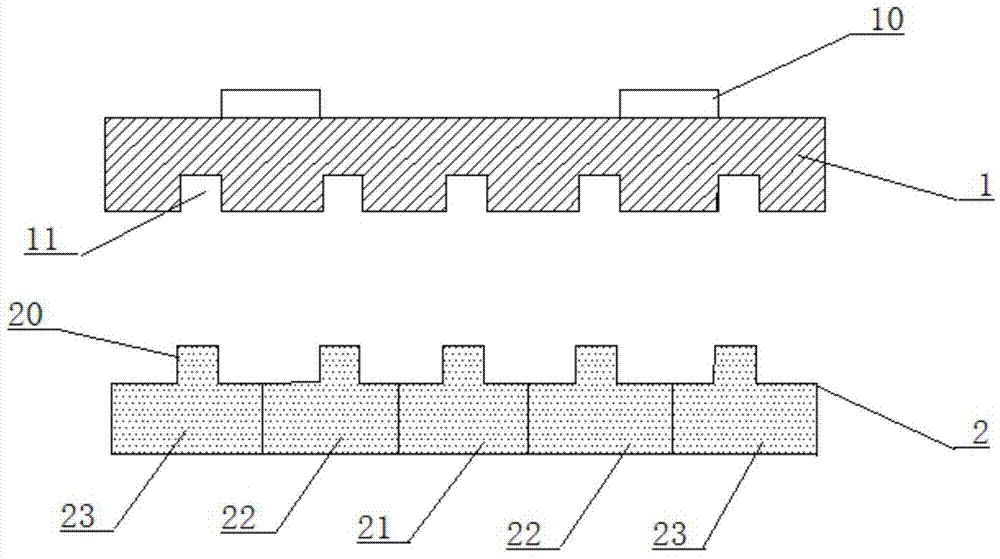

[0018] Such as figure 1 with figure 2 As mentioned, a yaw brake pad made of multiple materials is composed of a steel back 1 and a friction layer 2. There are bumps 10 on the steel back 1 and an embedding groove 11 where the steel back 1 and the friction layer 2 are in contact. To prevent the friction layer from falling off due to high pressure and strong vibration during high-strength work, the embedding groove 11 is designed as a square cross-section structure. At the same time, in order to ensure a smooth and pleasant high-strength work, the steel back is molded from high-strength steel.

[0019] The friction layer is composed of a heat-resistant layer 21, a wear-resistant layer 22, and a sound-absorbing protective layer 23 arranged in sequence from the inside to the outside, of which there is only one piece located in the heat-resistant layer 21, and the wear-resistant layer 22 and the sound-absorbing protective layer 23 are symmetrically distributed on the Both ends of the ...

Embodiment 2

[0021] Such as figure 1 with figure 2 As mentioned, a yaw brake pad made of multiple materials is composed of a steel back 1 and a friction layer 2. There are bumps 10 on the steel back 1 and an embedding groove 11 where the steel back 1 and the friction layer 2 are in contact. To prevent the friction layer from falling off due to high pressure and strong vibration during high-strength work, the embedding groove 11 is designed as a square cross-section structure. At the same time, in order to ensure a smooth and pleasant high-strength work, the steel back is molded from high-strength steel.

[0022] The friction layer is composed of a heat-resistant layer 21, a wear-resistant layer 22, and a sound-absorbing protective layer 23 arranged in sequence from the inside to the outside, of which there is only one piece located in the heat-resistant layer 21, and the wear-resistant layer 22 and the sound-absorbing protective layer 23 are symmetrically distributed on the Both ends of the ...

Embodiment 3

[0024] Such as figure 1 with figure 2 As mentioned, a yaw brake pad made of multiple materials is composed of a steel back 1 and a friction layer 2. There are bumps 10 on the steel back 1 and an embedding groove 11 where the steel back 1 and the friction layer 2 are in contact. To prevent the friction layer from falling off due to high pressure and strong vibration during high-strength work, the embedding groove 11 is designed as a square cross-section structure. At the same time, in order to ensure a smooth and pleasant high-strength work, the steel back is molded from high-strength steel.

[0025] The friction layer is composed of a heat-resistant layer 21, a wear-resistant layer 22, and a sound-absorbing protective layer 23 arranged in sequence from the inside to the outside, of which there is only one piece located in the heat-resistant layer 21, and the wear-resistant layer 22 and the sound-absorbing protective layer 23 are symmetrically distributed on the Both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com