Plating coating system, and metal piece product with imitation ceramic effect

A coating and coating technology, used in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient coating adhesion, poor coating adhesion, etc. The effect of strong adhesion and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation of the paint in the above-mentioned coating paint system is a high-speed impeller mixer with a relatively simple structure. It is a high-speed rotating shaft that can be lifted up and down by a hydraulic device. The lower end of the shaft is equipped with a horizontally placed and rotating shaft Disc impeller. When the high-speed impeller mixer is running, the dispersed material (including resin, diluent, additive, pigment, filler) advances violently along the centrifugal direction of the impeller, rushes to the wall of the barrel, and flows back up and down to the middle of the impeller, forming a vortex and impact Force and shear force to achieve the purpose of wetting and dispersing paints and pigments.

[0038] In the above coating method, the coating film thickness of the UV primer layer is 20-25 μm, leveled at 50-60°C for 5-8 minutes, and at 700-1000mJ / cm 2 solidified under the energy. Then, the product coated with UV primer is coated with inorga...

Embodiment

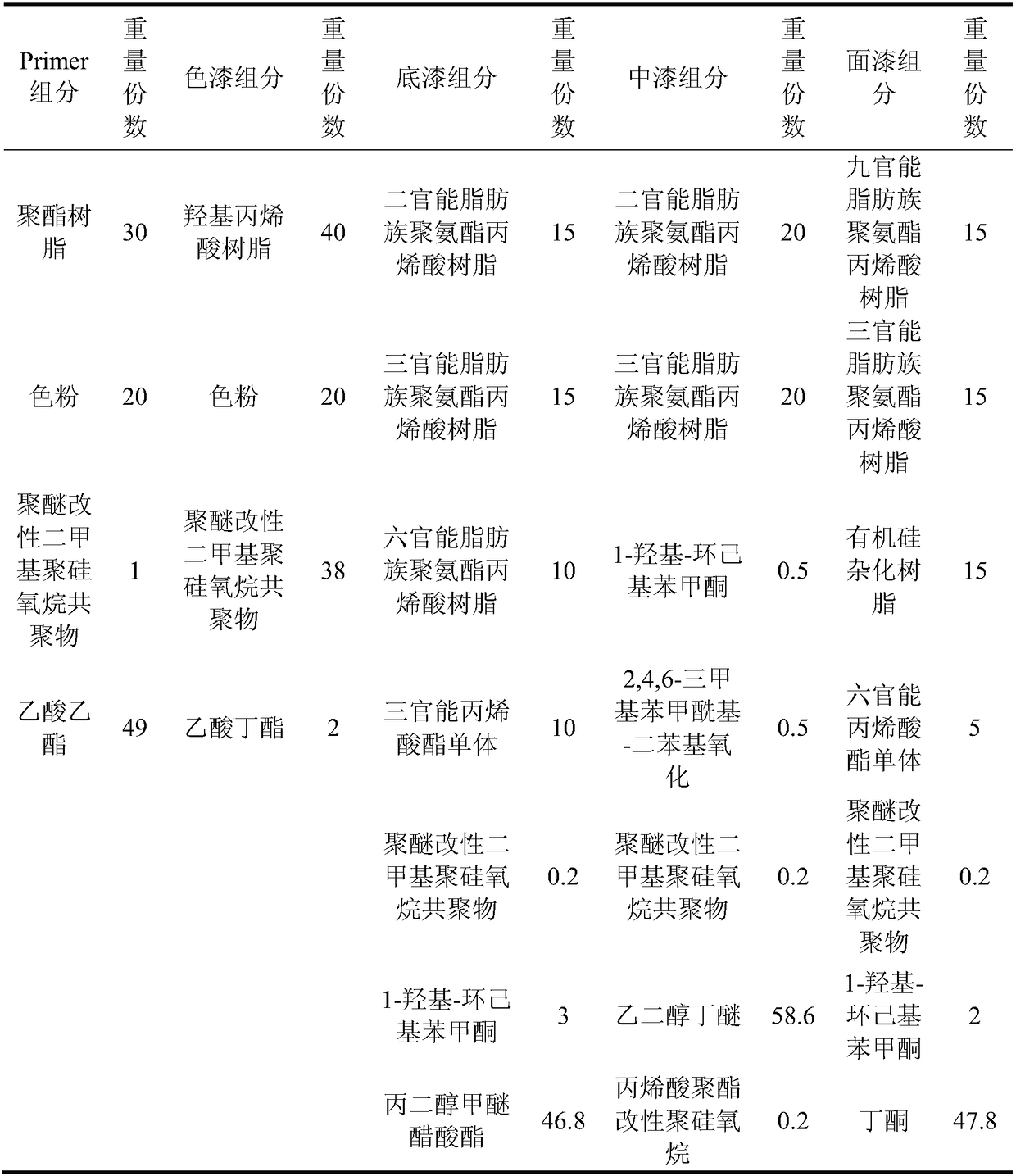

[0046] In each of the following examples:

[0047] Hydroxy acrylic resin was purchased from Toyobo, Japan, or Gaodian Chemical, Taiwan, China.

[0048] The difunctional aliphatic urethane acrylic resin was purchased from Sartomer Corporation of the United States, Cytec Corporation of the United States, or Changxing Chemical of Taiwan, China.

[0049] The trifunctional aliphatic urethane acrylic resin was purchased from Sartomer Corporation of the United States, Cytec Corporation of the United States, or Changxing Chemical of Taiwan, China.

[0050] The high-functional aliphatic polyurethane acrylic resin was purchased from Sartomer Company of the United States, Cytec Company of the United States, or Changxing Chemical of Taiwan, China.

[0051] The silicone hybrid resin was purchased from Sartomer Corporation of the United States, or from Cytec Corporation of the United States, or from Zhongshan Jishida.

[0052] The trifunctional acrylate monomer was purchased from EM232 of...

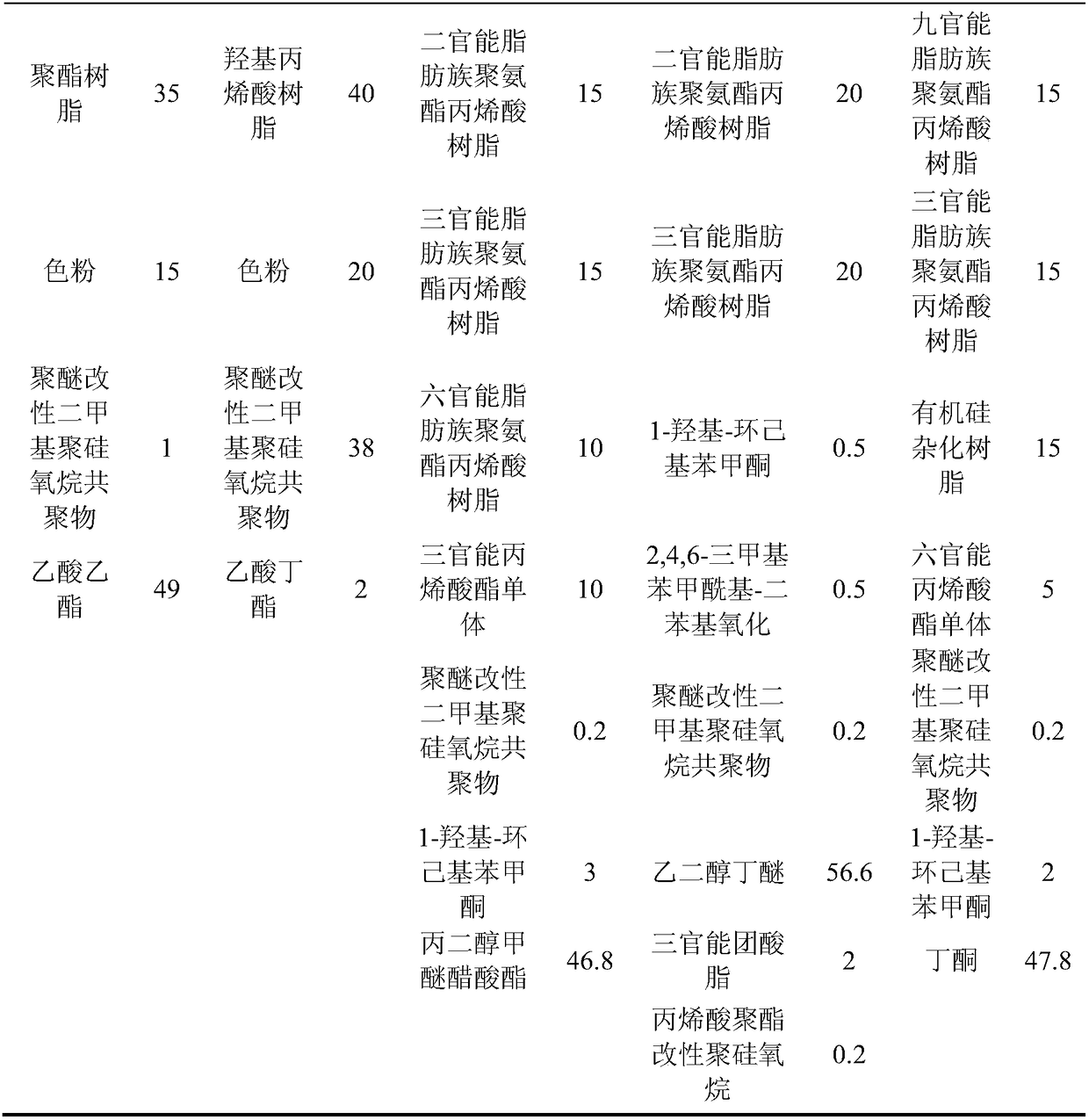

Embodiment 2

[0096] Embodiment 2 is to reduce the content of toner on the basis of embodiment 1 and solve the problem that the primer is lost in the 100-grid test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com