Durable antireflective film

a technology of anti-reflective film and anti-reflective coating, which is applied in the direction of synthetic resin layered products, instruments, transportation and packaging, etc., can solve the problems of loss of interfacial adhesion with the adjacent high refractive index layer, poor coating and optical cosmetic properties, and reduce the hardness and durability of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The recitation of numerical ranges by endpoints includes all numbers subsumed within the range (e.g. the range 1 to 10 includes 1, 1.5, 3.33, and 10).

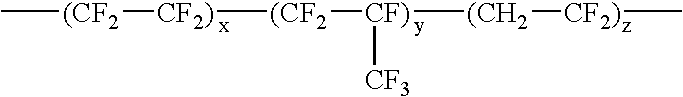

[0017]The phrase “free-radically polymerizable” refers to monomers, oligomers, and polymers having functional groups that participate in crosslinking reactions upon exposure to a suitable source of free radicals. Free-radically polymerizable groups include for example (meth)acryl groups, —SH, allyl, or vinyl. The free-radically polymerizable group may be halogenated with for example fluorine such as in the case of —COCF═CH2.

[0018]Preferred free-radically polymerizable monomer and oligomers typically comprise one on more “(meth)acryl” groups including (meth)acrylamides, and (meth)acrylates optionally substituted with for example fluorine and sulfur. A preferred (meth)acryl group is acrylate. Multi-(meth)acrylate materials comprise at least two polymerizable (meth)acrylate groups; whereas as mono-(meth)acrylate material has a singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com