Pollution-free tube-bundle separation-type permanent-magnet separating device being suitable for separating superfine magnetic particles

A magnetic separation device, separation device technology, applied in the direction of magnetic separation, high gradient magnetic separator, solid separation, etc., can solve the problem of difficult separation of low-concentration or ultra-low-concentration ultra-fine magnetic particles, high operation and maintenance costs, magnetic gathering Corrosion of substances and other problems, to achieve the effect of increasing fluid handling capacity, low cost, and convenient elution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

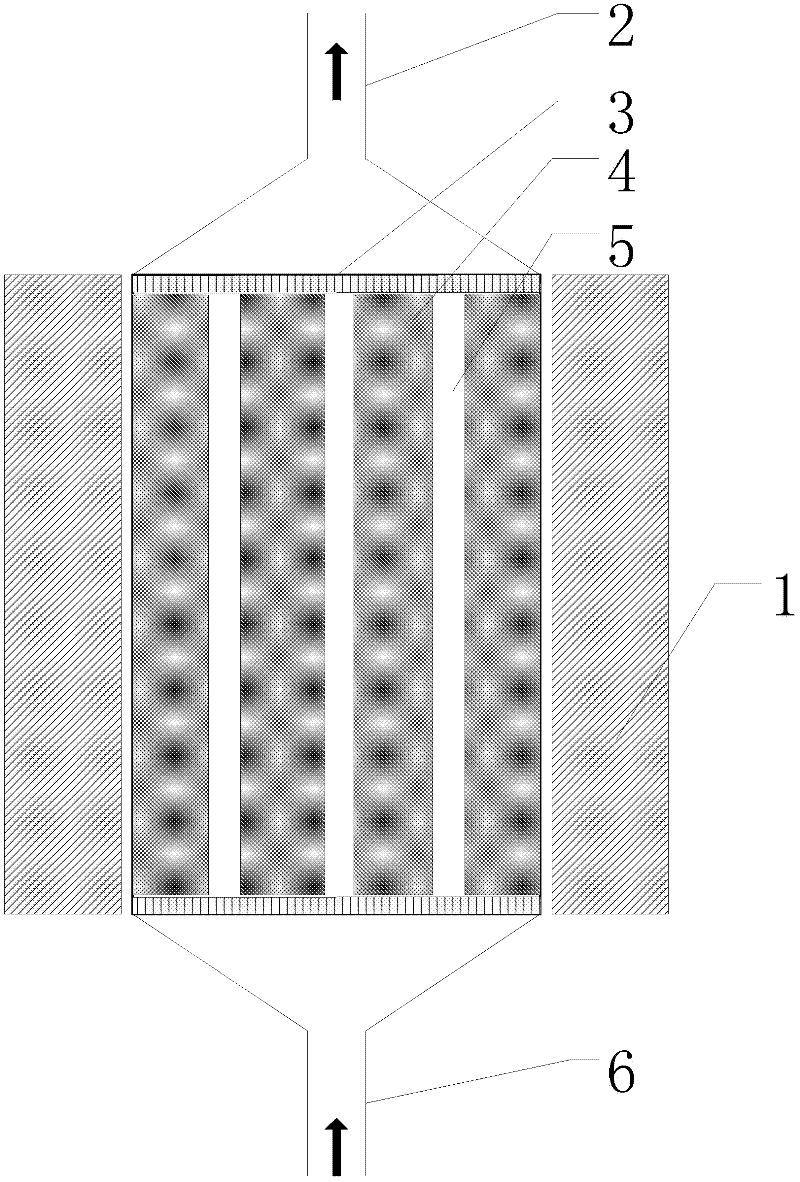

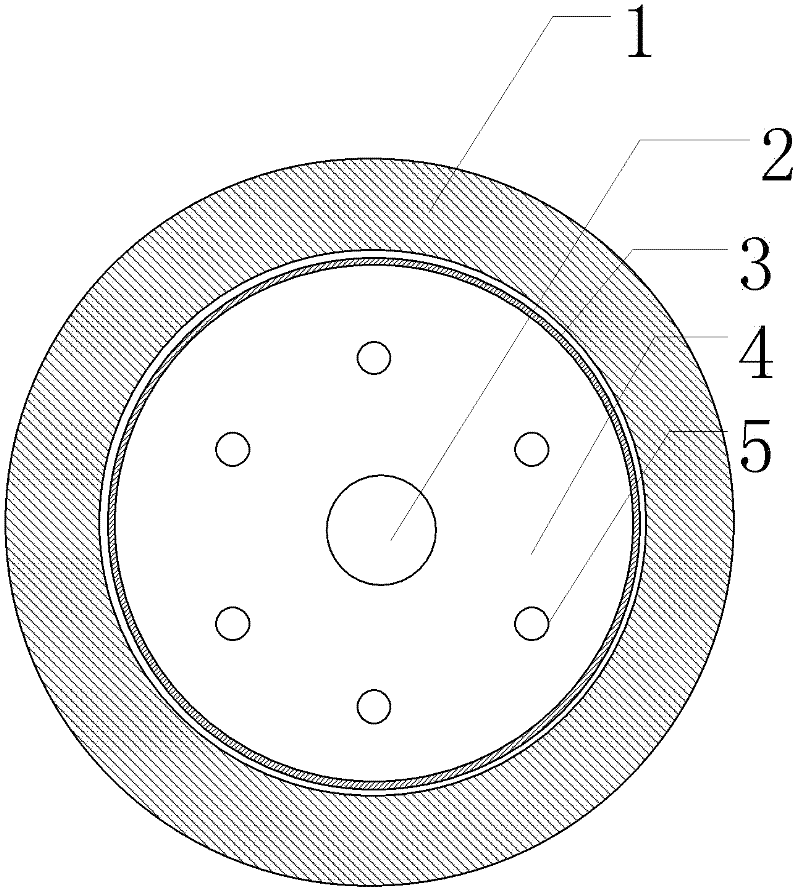

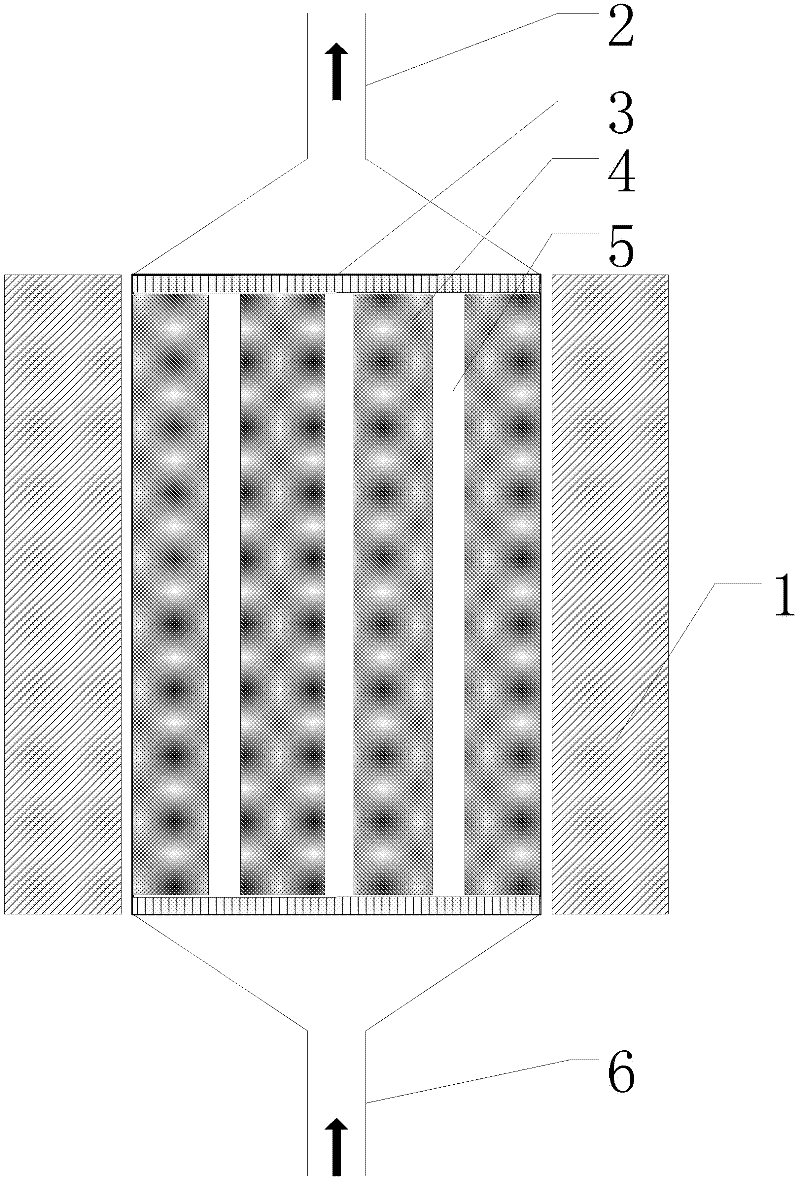

[0036] Such as figure 1 As shown, the pollution-free tube bundle isolation permanent magnet separation device suitable for ultrafine magnetic particle separation according to the present invention includes an annular permanent magnet 1 and a separation chamber, the annular permanent magnet provides a magnetic field for the separation chamber, and the annular permanent magnet The area of the magnet preferably covers the entire separation chamber. It is further preferred that the vertical length of the annular permanent magnet is the same or nearly the same as that of the separation chamber. The ring-shaped permanent magnet 1 outside the separation chamber is fixed on the rotating shaft, and the magnetic field strength is 3000-4000 Oersted. The bottom of the separation chamber has a material inlet and a cleaning water inlet 6, and the top has a material outlet and a cleaning water outlet 2. The separation chamber contains a plurality of isolation tubes 5, and the outside of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com