Machine for harvesting tall stalk crops

A technology for high-stem crops and harvesters, which is applied to the chassis of harvesters, cutters, and agricultural machinery, and can solve problems such as clutter, inconvenient collection, and manual removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

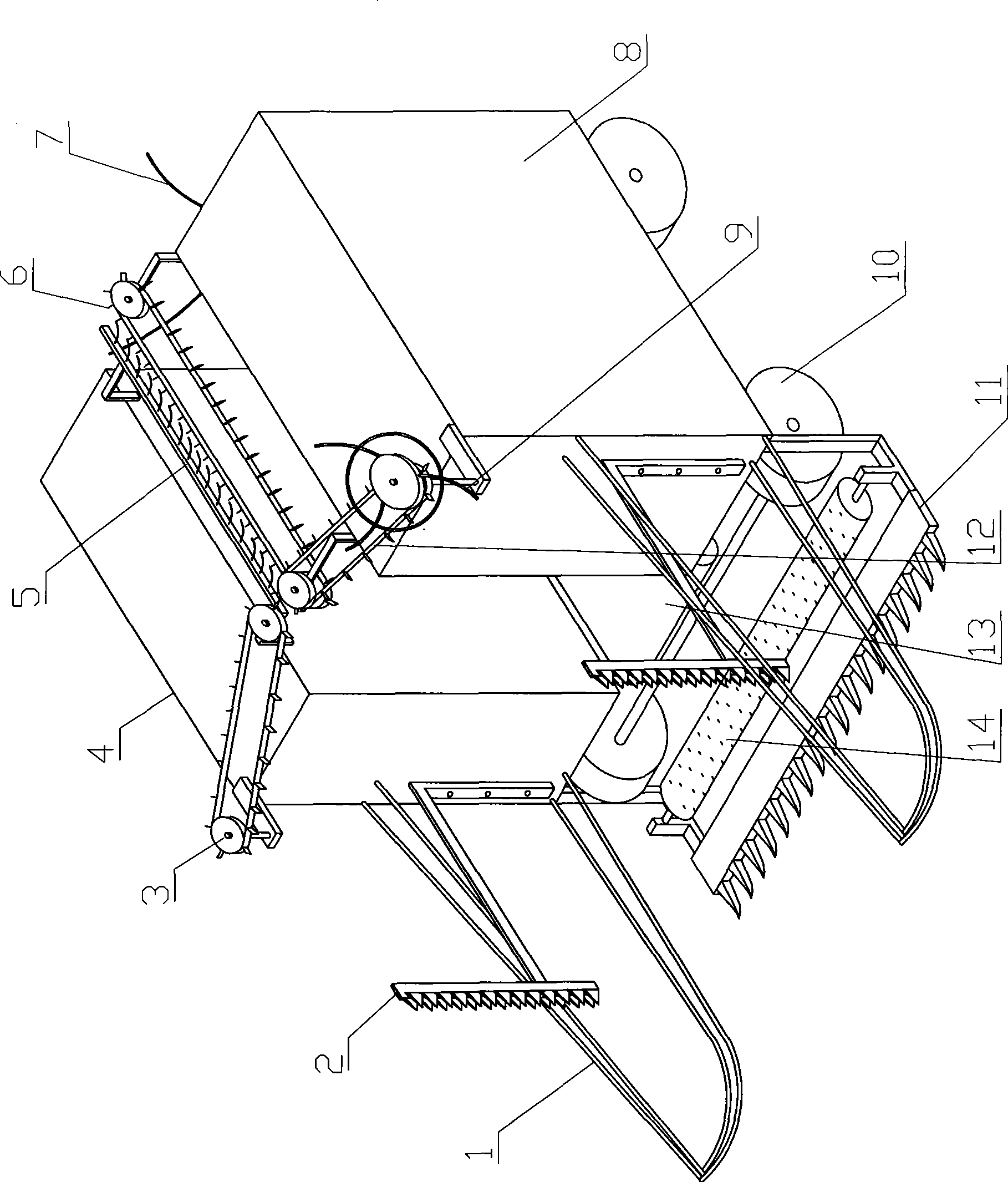

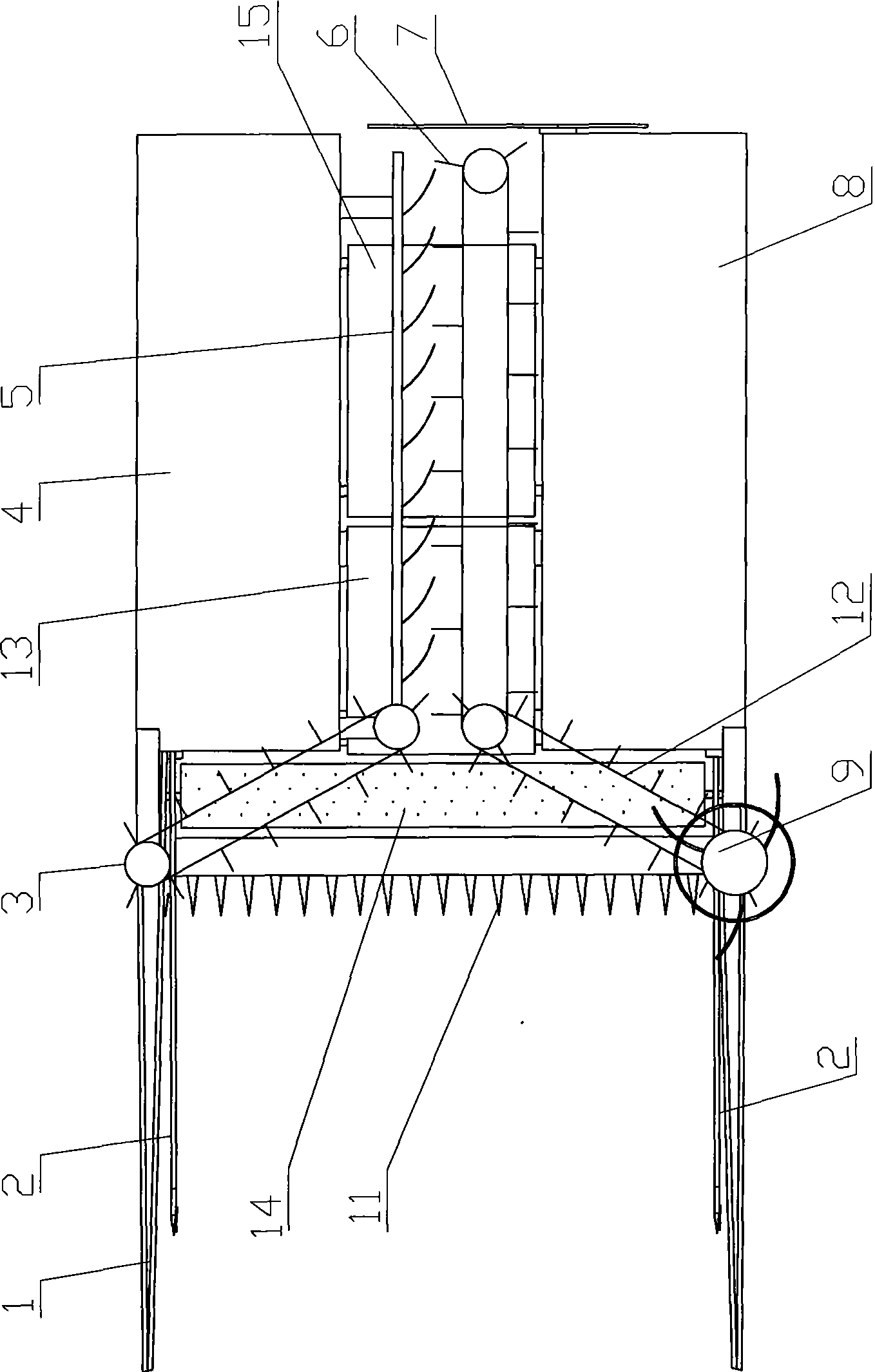

[0017] Such as figure 1 , figure 2 A kind of specific embodiment shown, it comprises crop divider 1, side cutter 2, conveyer I3, power unit 4, extrusion bar 5, conveyer II6, intermittent feeding device 7, driver's cab 8, pull out material Device 9, chassis 10, horizontal cutter 11, conveyor III12, conveyor IV13, grass pressing wheel 14 and collection table 15.

[0018] Power unit 4, cab 8 and chassis 10 form a motor vehicle. The power unit 4 and the driver's cab 8 are arranged side by side on the chassis 10, and there is a crop passage along the traveling direction of the motor vehicle between the power unit 4 and the driver's cab 8. Conveyor IV13 is arranged on the front portion at the bottom of the crop passage, and the collection platform 15 is located at the rear at the bottom of the crop passage (such as figure 2 shown).

[0019] Grain divider 1, side cutter 2, horizontal cutter 11, grass wheel 14 are fixed on the head of motor vehicle. There are two side cutters 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com