Hand-push type multifunctional plant pruning machine

A multi-functional, hand-push technology, which is applied to the chassis of harvesters, cutters, and agricultural machinery, can solve the problems of gasoline engines with high noise, low work efficiency, and high labor intensity, so as to improve cutting efficiency and work The effect of improving efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

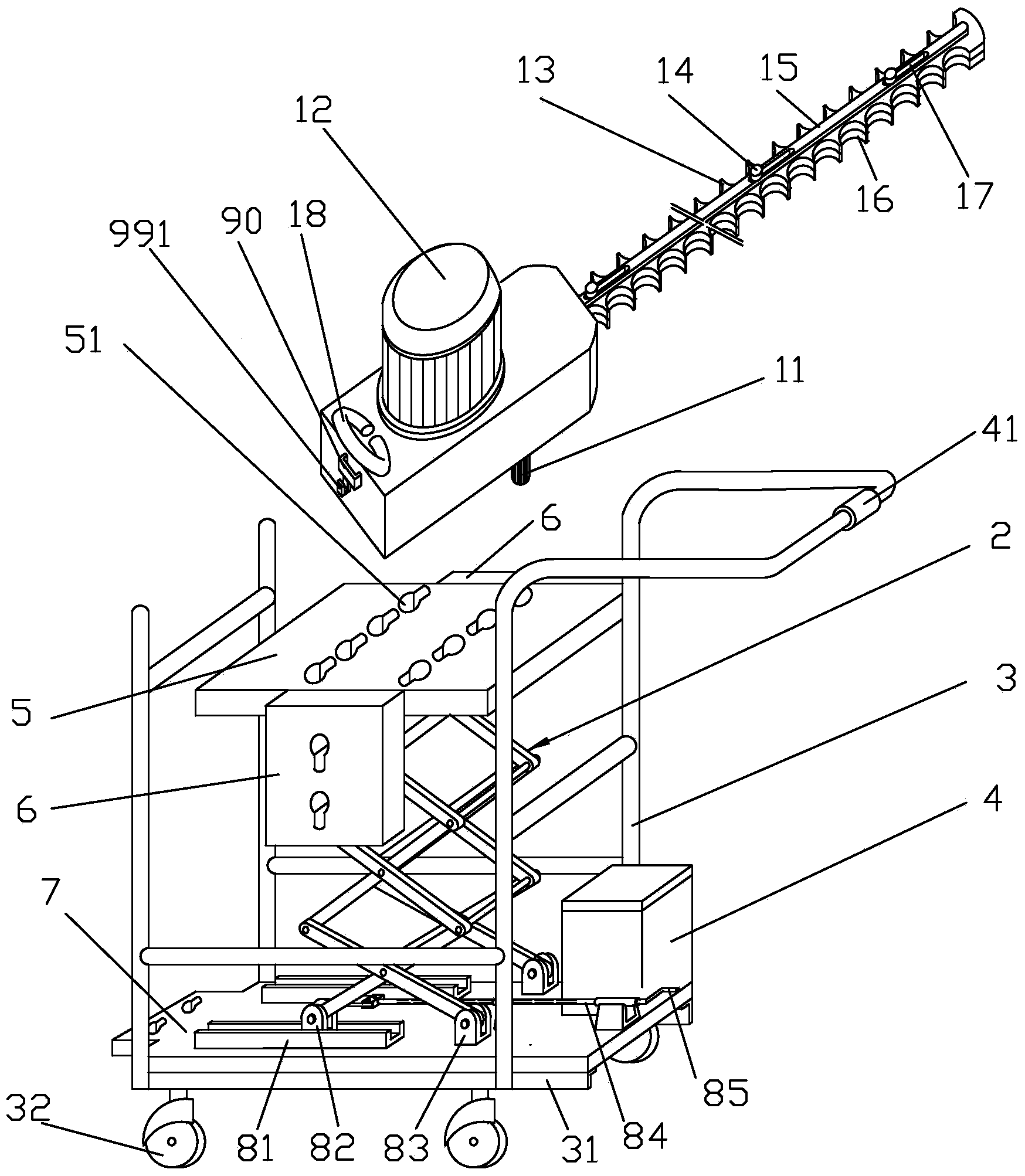

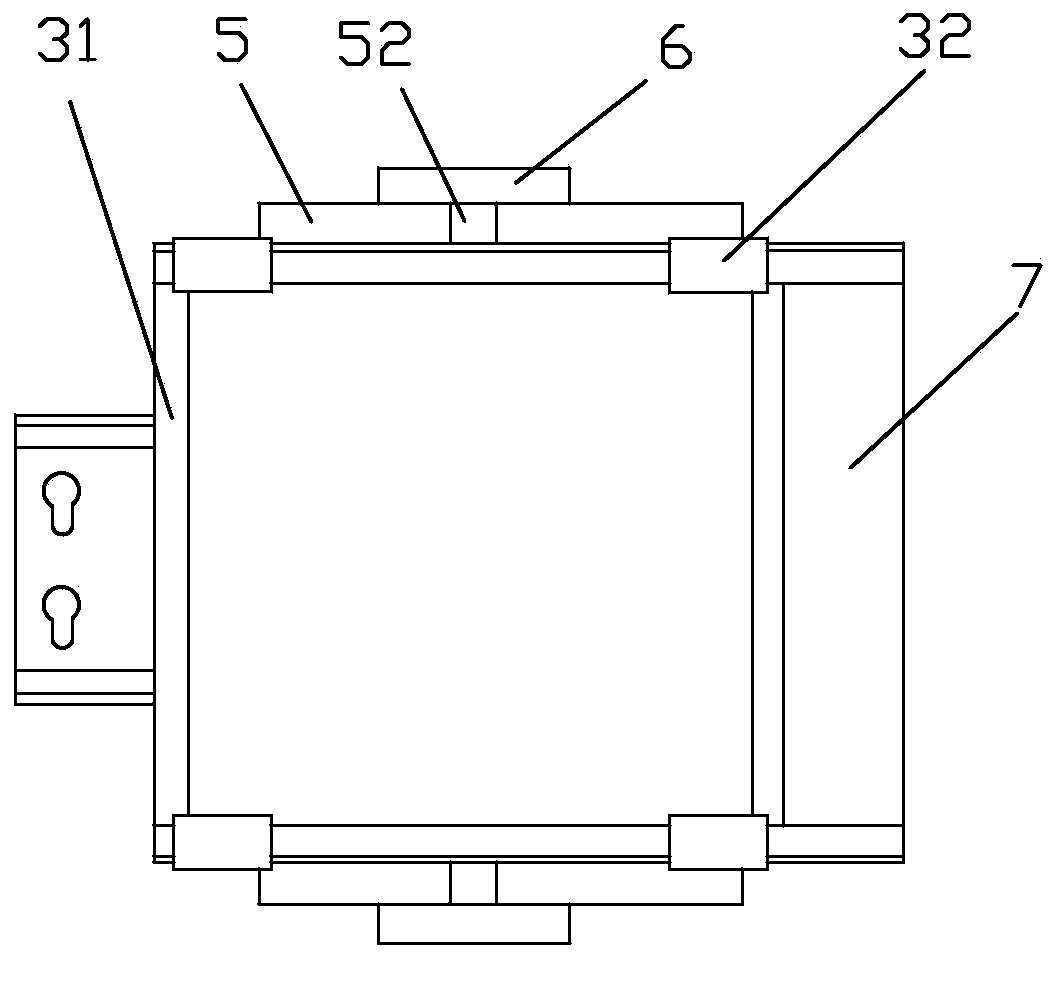

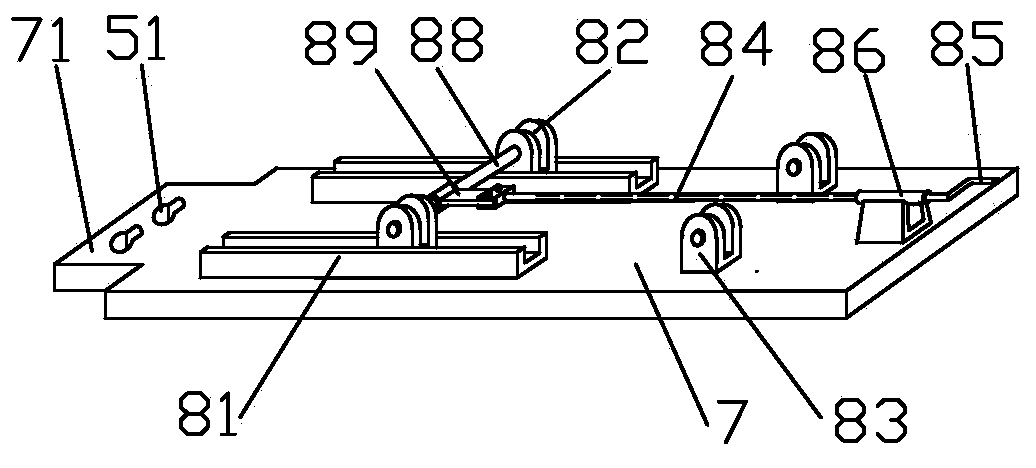

[0028] like Figure 1-Figure 4 As shown, the present embodiment hand-push multifunctional plant trimmer includes a four-wheeled trolley and an electric hedge trimmer composed of a power part A and a scissors part B. Hand barrow comprises vehicle frame 3, wheel 32, underframe 31 and the base plate 7 that is fixed on the underframe. The power part A comprises a motor 12 and a housing 9, the motor and a hand-held handle 18 are installed on the top surface of the housing, and the bottom surface of the housing is formed with two vertical columns 10, 11, wherein the length of the column 11 is greater than that of the column 10 length so that it can be held by hand when needed. Knives and scissors B is the prior art, including a moving knife 16 and a fixed knife 13, the fixed knife is equipped with a pressure plate 15 fixed to the housing, a slide groove 17 is opened on the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com