Heated structural member thermal shock and thermal fatigue test stand

A test bench, thermal shock technology, used in thermometers, heat measurement, lighting and heating equipment with directly sensitive electrical/magnetic components, etc., can solve the problems of long test cycle and test cost, and shorten the development time. The effect of cycle and saving test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] 1. The overall composition of the thermal shock and thermal fatigue test bench for heated components

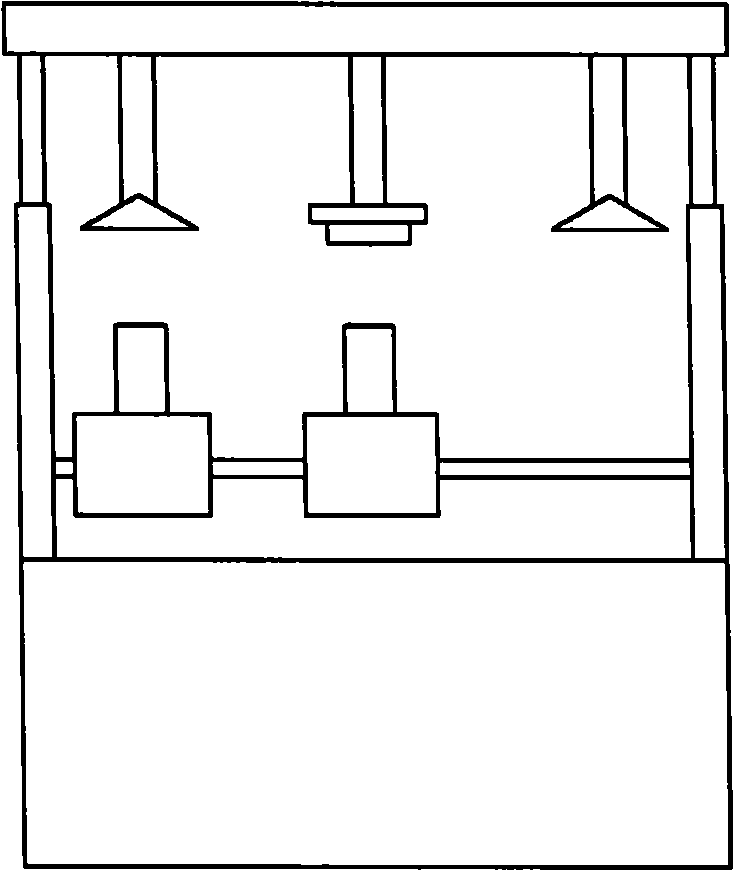

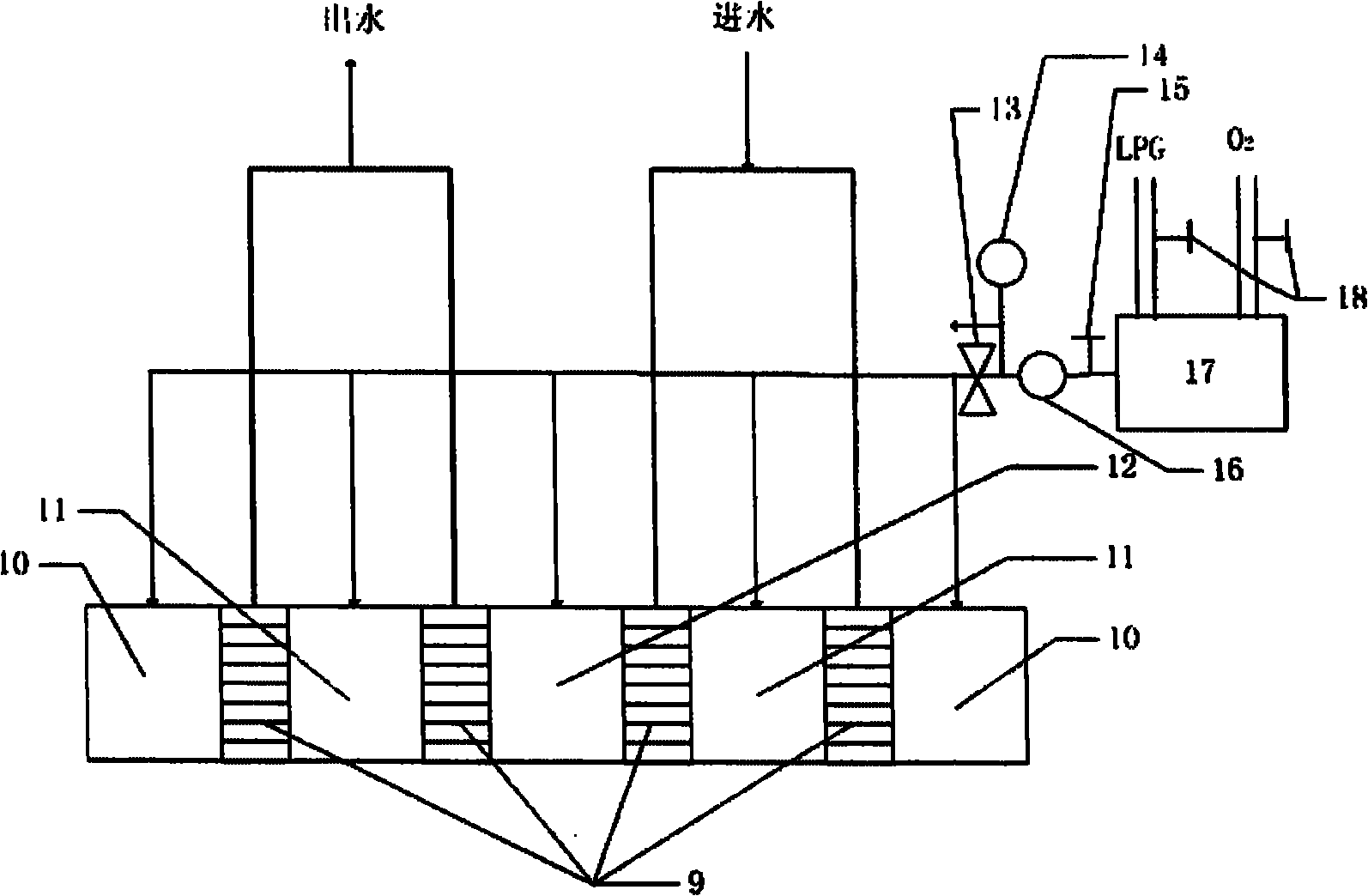

[0030] The test bench is composed of two parts, the test bench and the control system. Its shape is as follows: figure 1 shown. According to the functions, it includes: specimen installation platform and its traveling mechanism, specimen temperature detection system, gas heating system, cooling system, safety and alarm system, control system, monitoring and data storage system, etc.

[0031] 2. Introduction of each part of the test bench

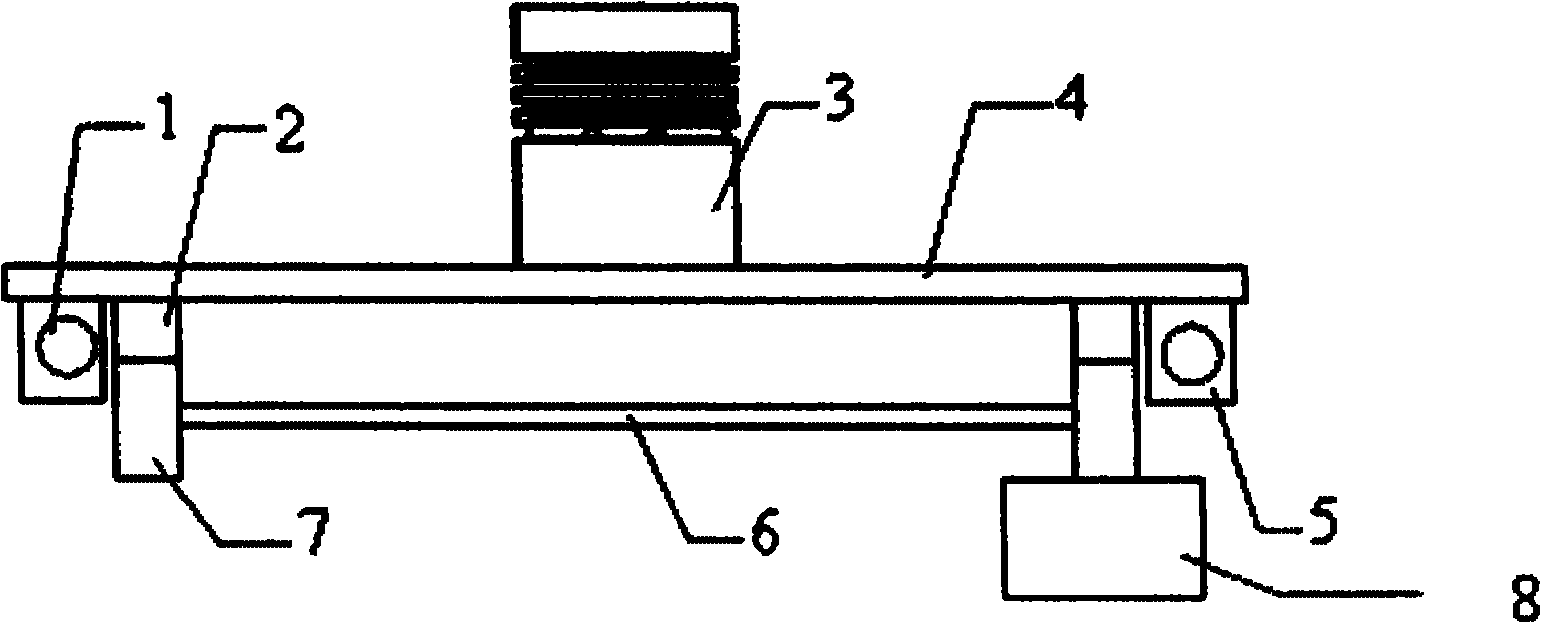

[0032] ·Test piece installation platform and walking mechanism

[0033] Such as figure 2 As shown, the movable test piece installation platform 4 is set on the test bench, and the traveling mechanism is arranged below it; The sleeve 5 and the rack 2 are fixed under the test piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com