Device for testing hardness, fracture toughness and residual stress of brittle material with indentation method

A technology for brittle materials and fracture toughness, applied in the direction of testing material hardness, measuring devices, analyzing materials, etc., can solve the problems of cumbersome testing process, high professional requirements, high maintenance costs and testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

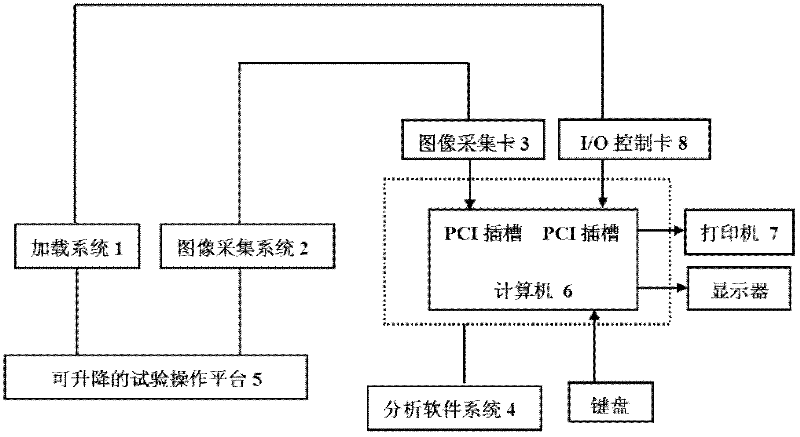

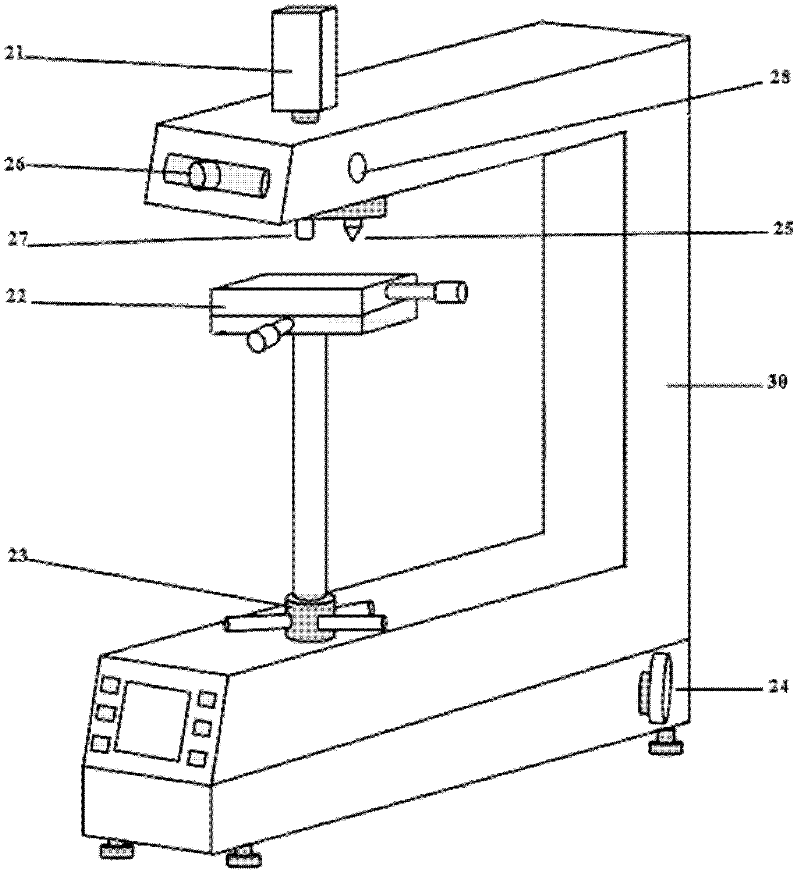

[0050] A device for testing hardness, fracture toughness and residual stress of brittle materials by indentation method, characterized in that the device includes a frame 30 on which an eyepiece 26, a liftable test operation platform 5 and an adjustment wheel 24 are arranged, The frame 30 is provided with a loading system 1;

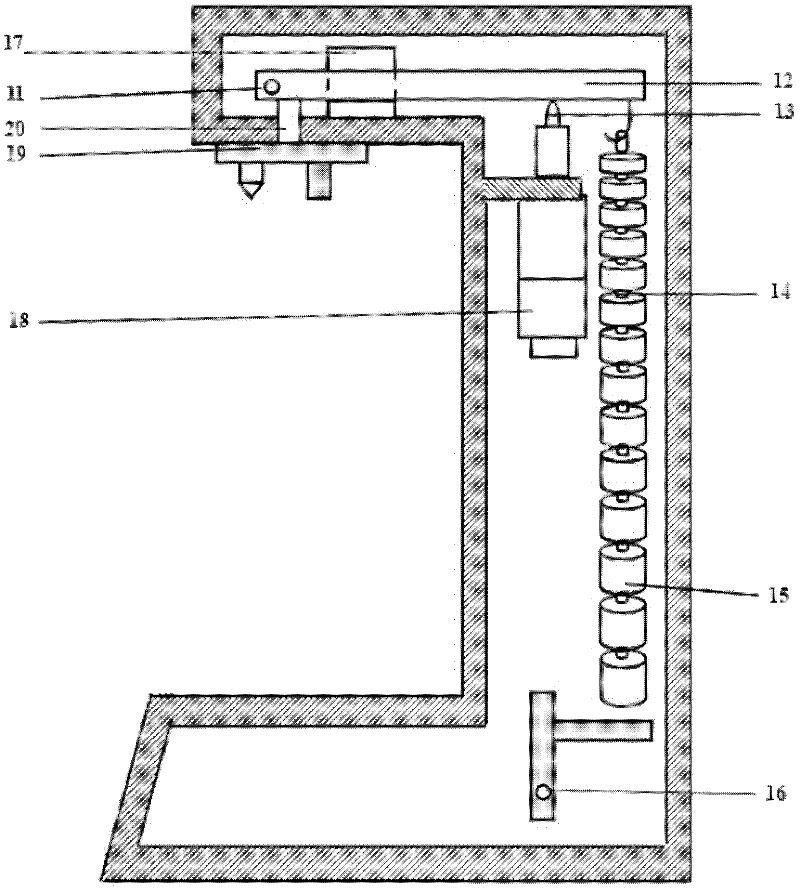

[0051] The loading system 1 includes a fixed support 11, a lever 12, a push rod 13, a suspension rod 14 and a second motor 18, wherein,

[0052] The fixed support 11 of the loading system 1 is connected with the fixed support 28 on the frame 30, and is used to fix one end of the lever 12, and the other end of the lever 12 is provided with a suspender 14, and the suspender 14 is composed of a plurality of weights 15 Composition, at one end of the fixed support 11 close to the lever 12, the intermediate spindle 20 is connected below the lever 12, the intermediate spindle 20 passes through the opening above the turntable 19 and connects with the Vickers ind...

Embodiment 2

[0061] Adopt the device of embodiment 1 to be able to test the microhardness of material, can also test the fracture toughness of interface of brittle material and brittle coating film system, the residual stress at the measured position place simultaneously, the step of specific embodiment is as follows:

[0062] The first step is to prepare the sample. The thermal barrier coating ceramic material is sprayed on the high-temperature nickel alloy substrate by using the plasma spraying process. The composition of the coating system of the sample is: the transition layer material is NiCrAIY alloy, and its thickness is about 150 μm; the ceramic powder material is 8wt% Y 2 o 3 -ZrO 2 , The thickness of the sprayed ceramic layer is about 350 μm. In order to consider the effect of high temperature oxidation on the interfacial bonding performance of the thermal barrier coating system, some original samples were subjected to high temperature heat treatment at 1100 °C. Then the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com