Lithium ion battery thermal performance testing method

A lithium-ion battery and testing method technology, applied in calorimeters, measuring devices, measuring heat, etc., can solve the problem of inability to obtain the change of the heating power of the lithium-ion battery with time, the inability to accurately judge the cycle life and safety of the power battery pack , affecting the widespread promotion and application of lithium-ion batteries, etc., to achieve the effect of improving market application prospects, low testing costs, and significant production and practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

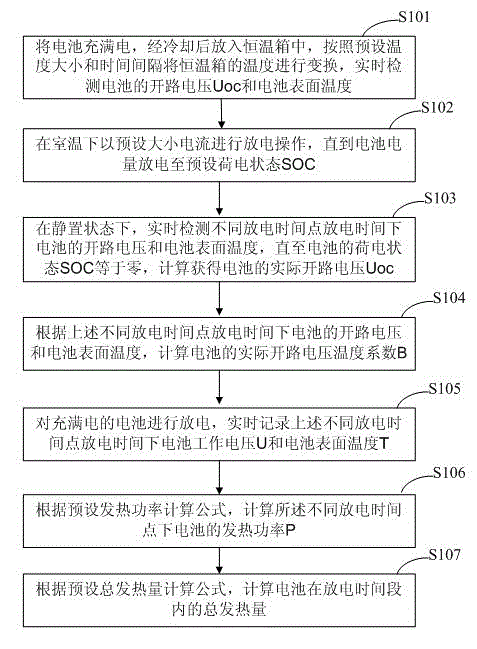

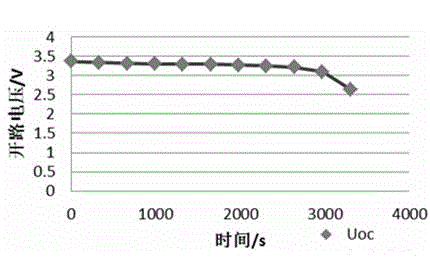

[0040] see figure 1 , the present invention provides a method for testing the thermal performance of a lithium-ion battery. By testing the heating power of a lithium-ion battery during discharge, the variation of heating power with discharge time, and the total heating value, battery manufacturers can Accurately grasp the thermal performance data of lithium-ion batteries during discharge, and then make accurate judgments on the cycle life and safety of power battery packs. The method specifically may include the following steps:

[0041] Step S101: Fully charge the battery, put it into an incubator after cooling (for example, an incubator that can be adjusted within the temperature range of 5-35°C, and when a certain temperature is selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com