Optimal energy-saving method for controlling surface pollutant discharge of steam boiler

A technology for surface sewage discharge and energy-saving control, which is applied in control systems, steam generation, boiler cleaning devices, etc., and can solve problems such as non-pollution control schemes and excessive emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

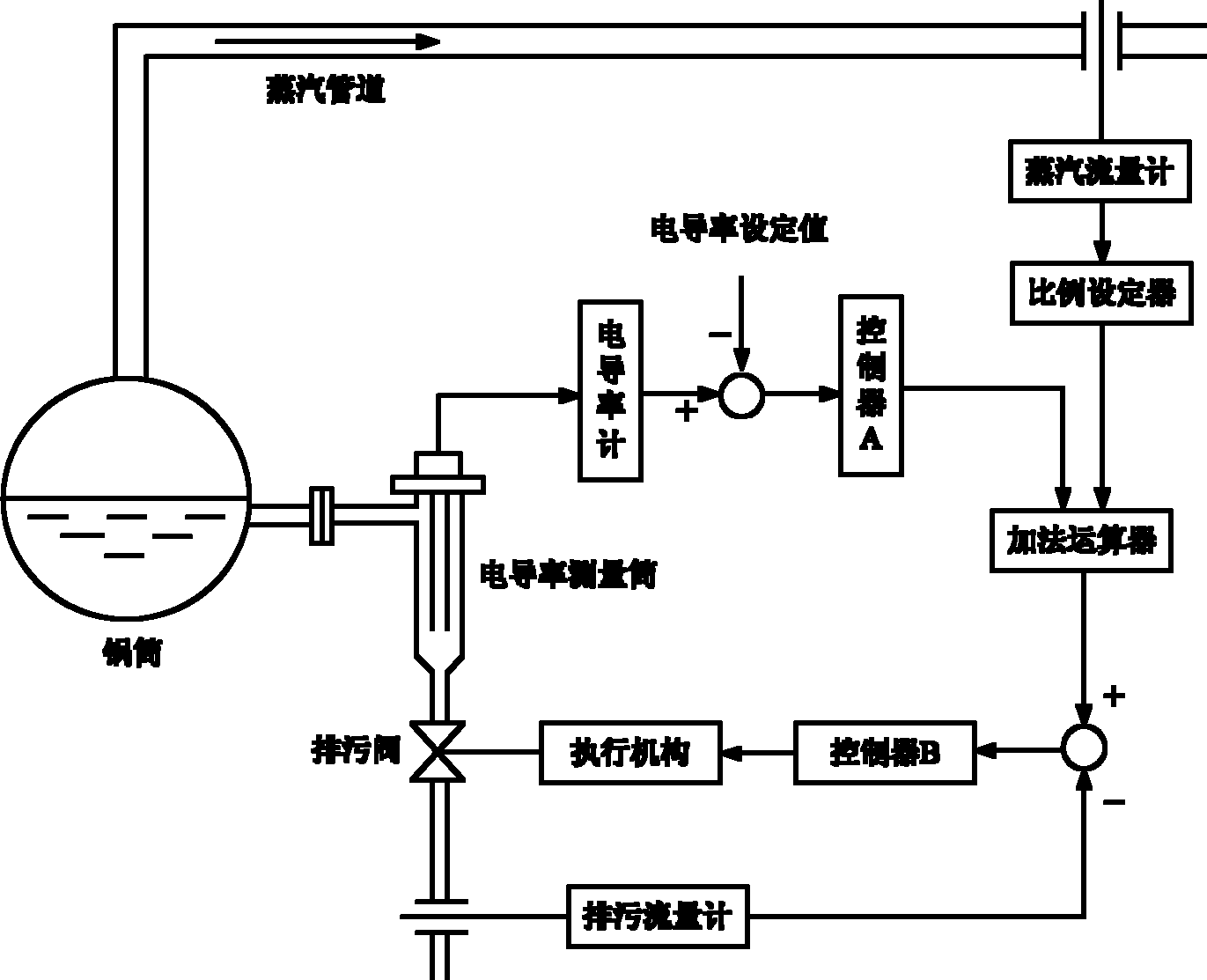

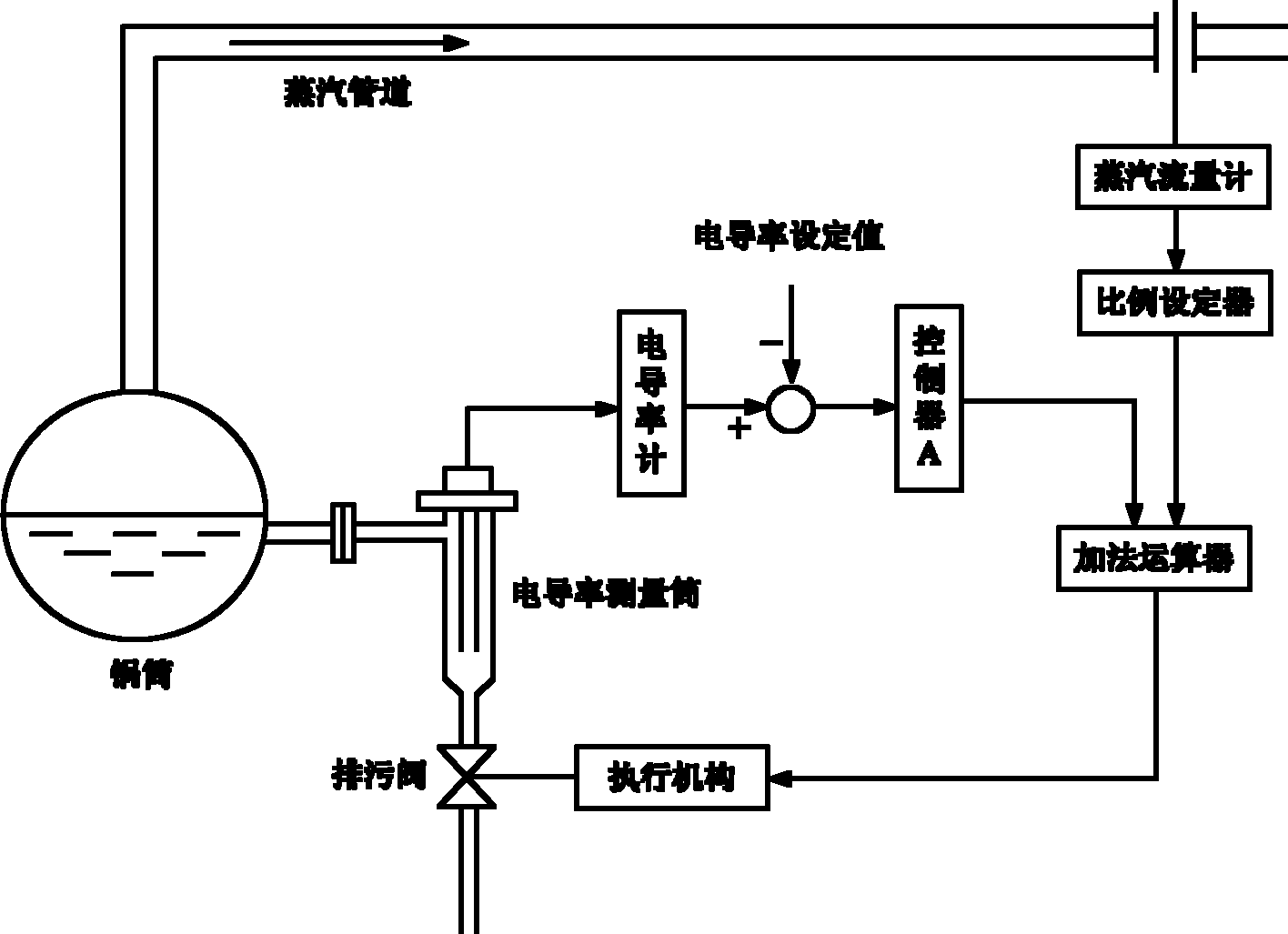

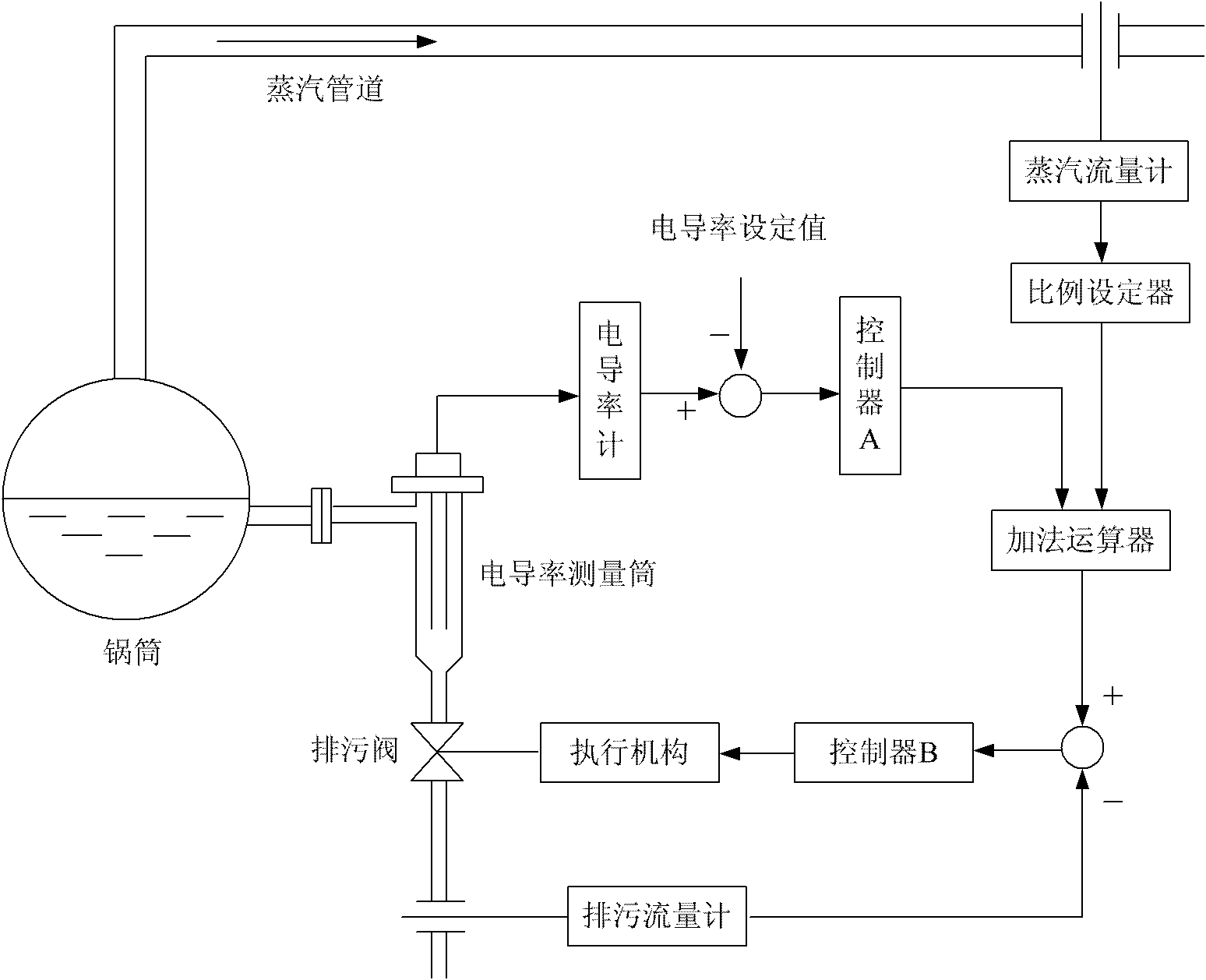

[0018] The composition of the surface pollution discharge optimization energy-saving control system proposed by the present invention is as follows: figure 1 shown. The steam flow signal measured by the flowmeter installed on the steam pipe of the boiler is multiplied by the proportional coefficient according to the formula (1) in the proportional setter to obtain the theoretically calculated initial value of the blowdown flow. Temporarily assume that the other input signal is 0) output the command signal of the blowdown flow, compare the command signal with the actual flow measured by the blowdown flowmeter, if there is any difference, the controller B will push the actuator to change the blowdown valve opening Degree, the blowdown flow is corrected to make it meet the requirements of formula (1). The action speed of this proportional control is very fast, except th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com