Wheel moving type rotor compressor

A rotor compressor and wheel-driven technology, applied in the field of refrigerant compressors, can solve the problems of limiting the application field of air energy heat pumps, motor burnout, etc., and achieve the effects of avoiding motor burnout, high compression displacement, and high compression ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

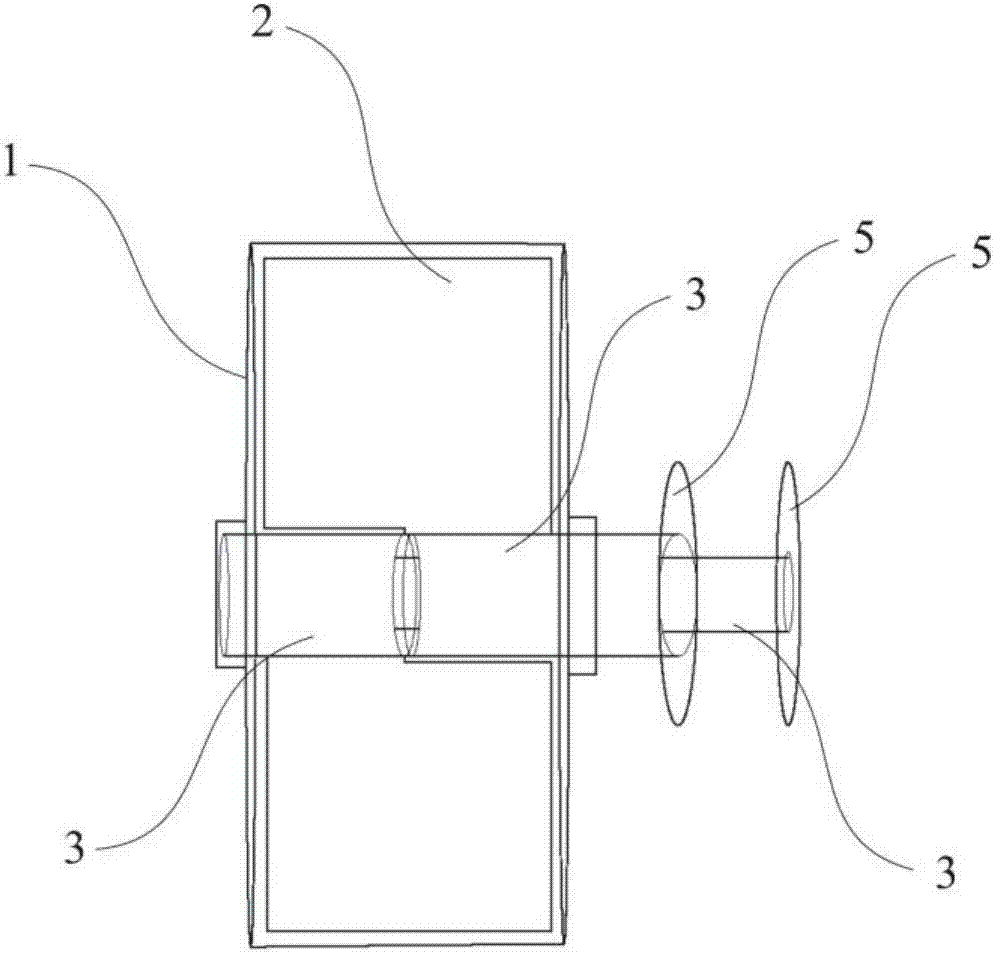

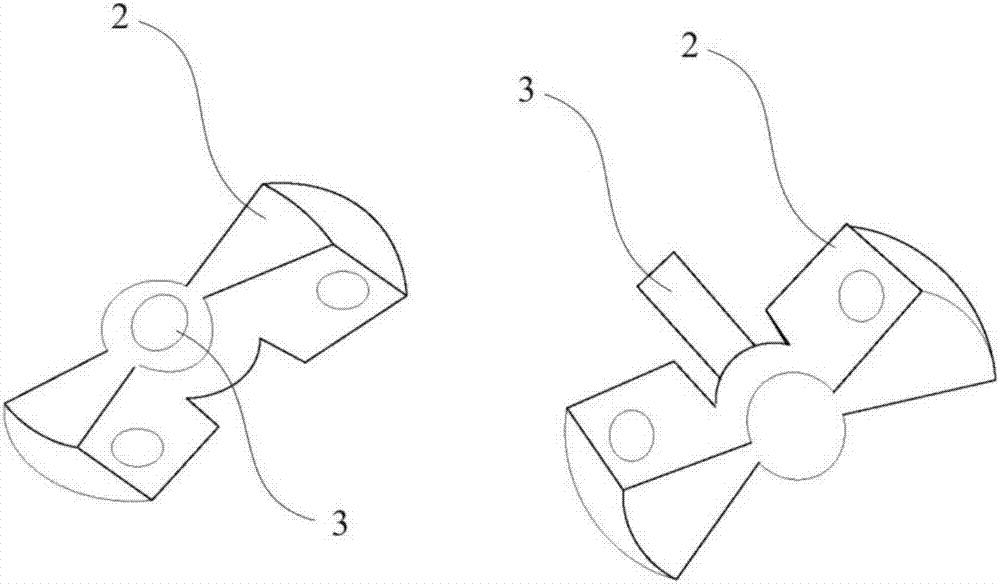

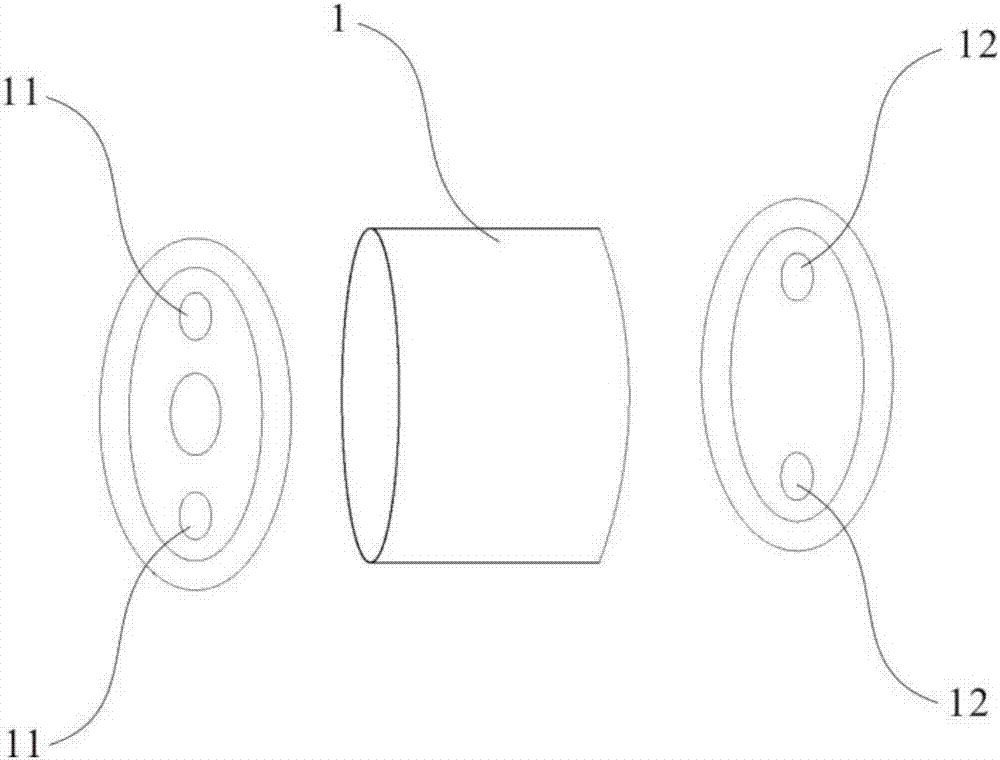

[0023] refer to figure 1 and Image 6 As shown, one embodiment of the present invention is a wheel-driven rotor compressor, including a compression cavity 1, the compression cavity 1 is cylindrical, and the end covers at both ends of the compression cavity 1 need to be respectively provided with air intake port 11 and air outlet 12, the structure of the compression cavity 1 is as follows image 3 shown; more importantly, two wheel blades 2 are installed inside the aforementioned compression cavity 1, and the structure of the two wheel blades 2 is as follows figure 2 As shown, and the positions of the two rotating blades 2 are staggered from each other, the two rotating blades 2 also need to cooperate with the internal structure of the compression chamber 1, specifically the radial outer edges of the two rotating blades 2 It is in close contact with the inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com