Adjustable die frame for heat exchanger micro-diameter thin-wall pipe bending die

A thin-walled pipe, adjustable technology, applied in the field of aerospace science, can solve the problems of lower forming quality, difficult positioning, flattening of cross-section, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

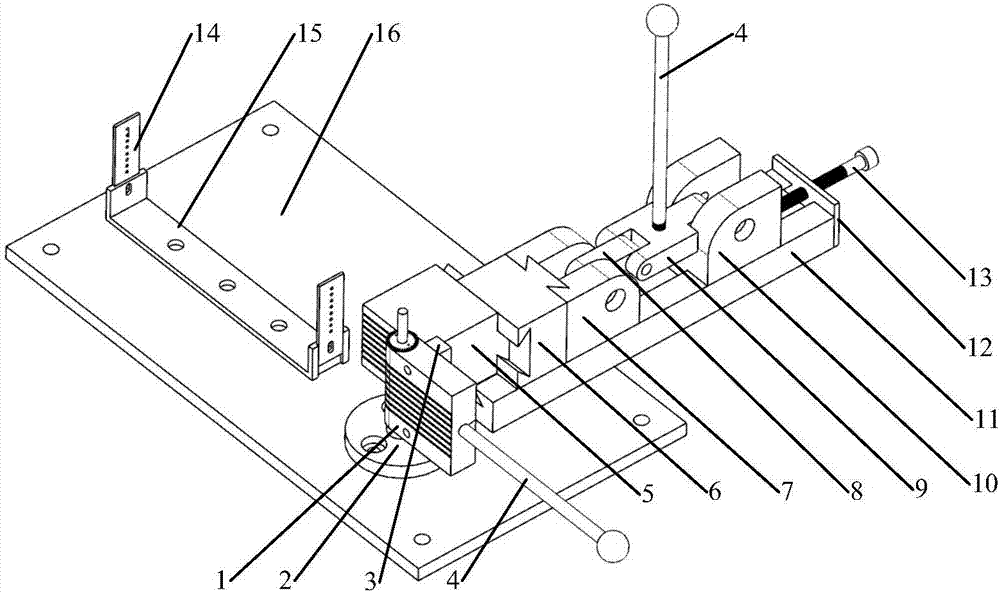

[0052] The present invention is an adjustable formwork used for bending molds of micro-diameter thin-walled pipes of heat exchangers, see figure 1 As shown, it is composed of three parts: a pressing part, a fixed connecting part and a guiding part. The connection relationship between them is: the guide part is fixed on the workbench, the pressing part is constrained to move in a certain direction on the guide part, and the guide part and the workbench are connected by threads.

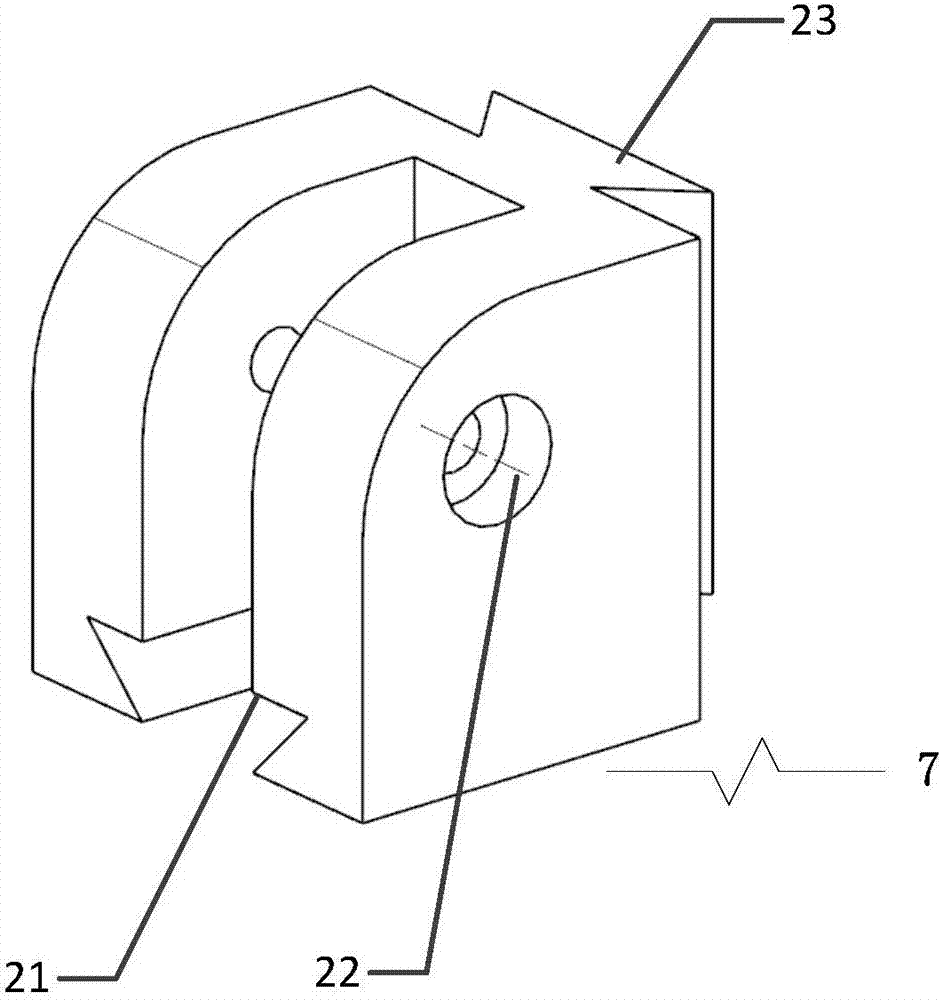

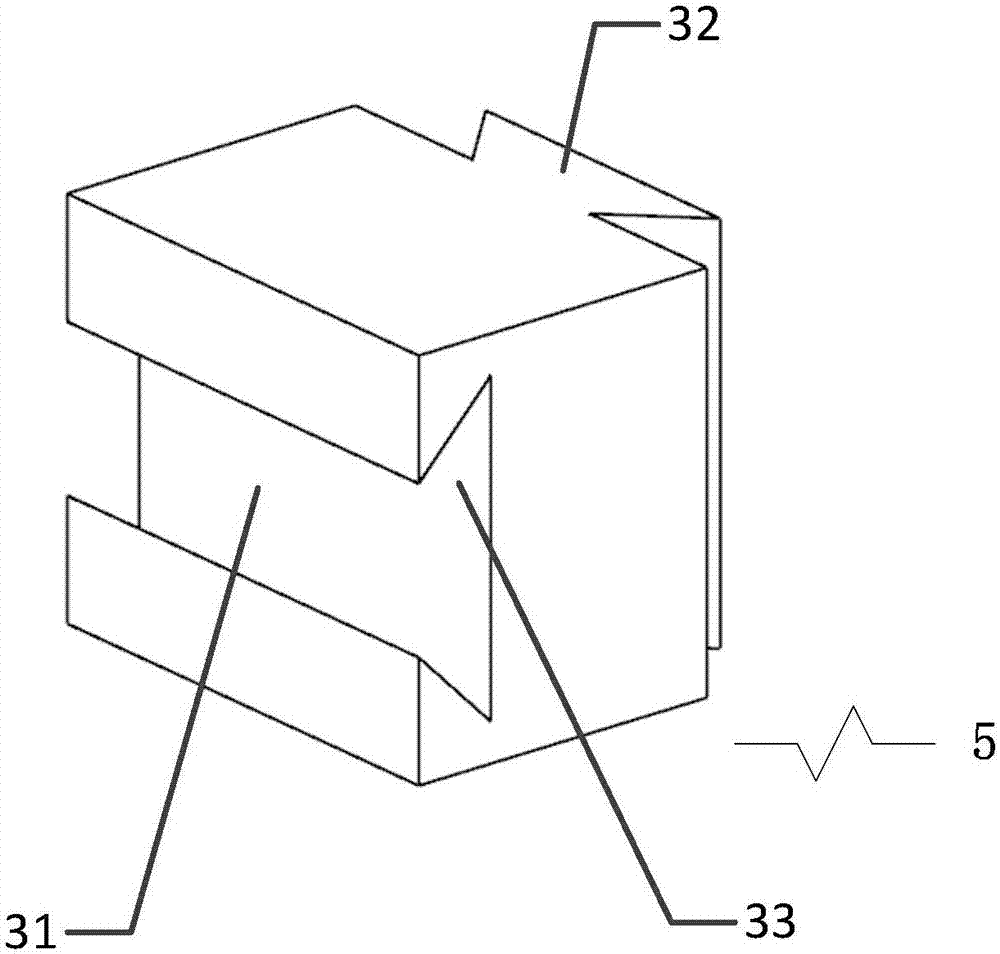

[0053] In the described pressing part, it is made up of adjusting block 6, front pressing block 7, front crank block 8, rear crank block 9, rear pressing block 10, push rod 4, and the connection relationship between them is as follows: image 3 As shown, the adjustment block 6 is connected with the front compression block 7 through the rear dovetail groove structure, which can ensure its displacement in the compression direction; the front compression block 7 and the slide rail 11 are flexibly connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com