Automatic two-gun welding for heating stove

A heating furnace, automatic welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment and other directions, can solve the problems of low welding efficiency, low firmness, easy to fall off during use, etc. Low manufacturing cost and improved welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

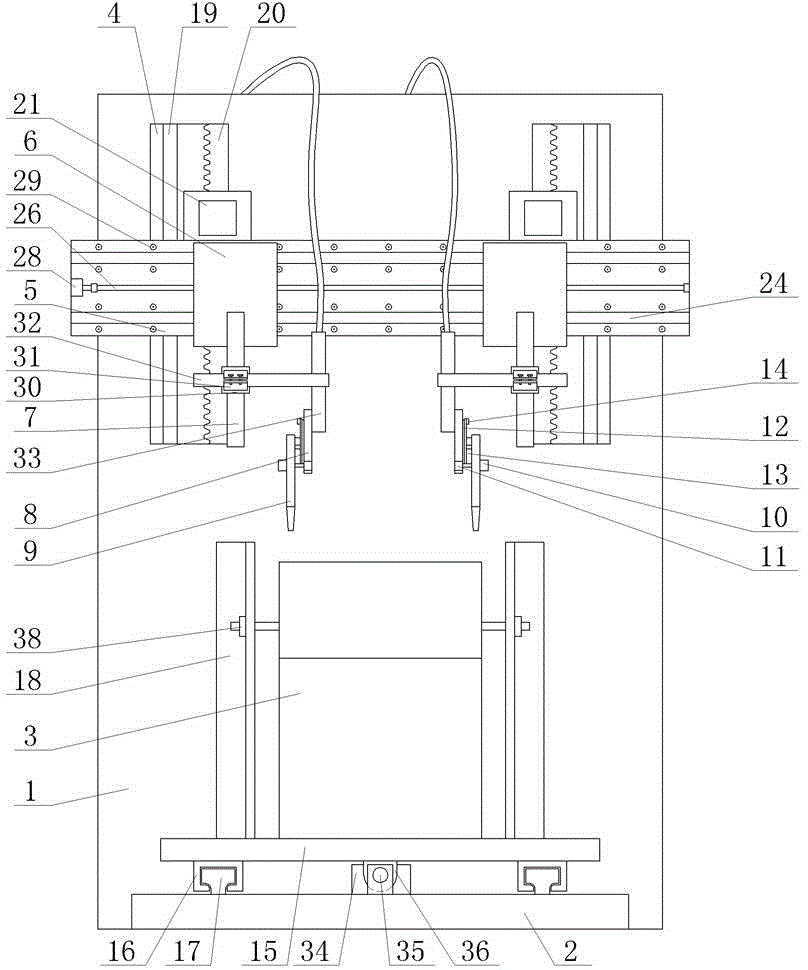

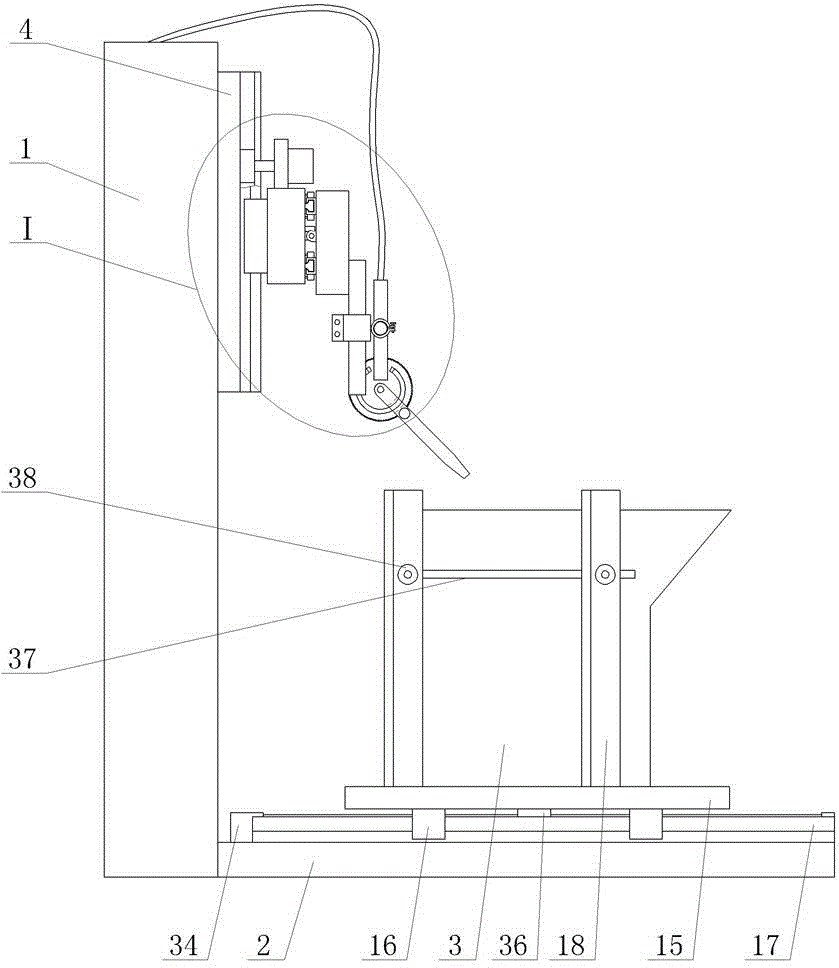

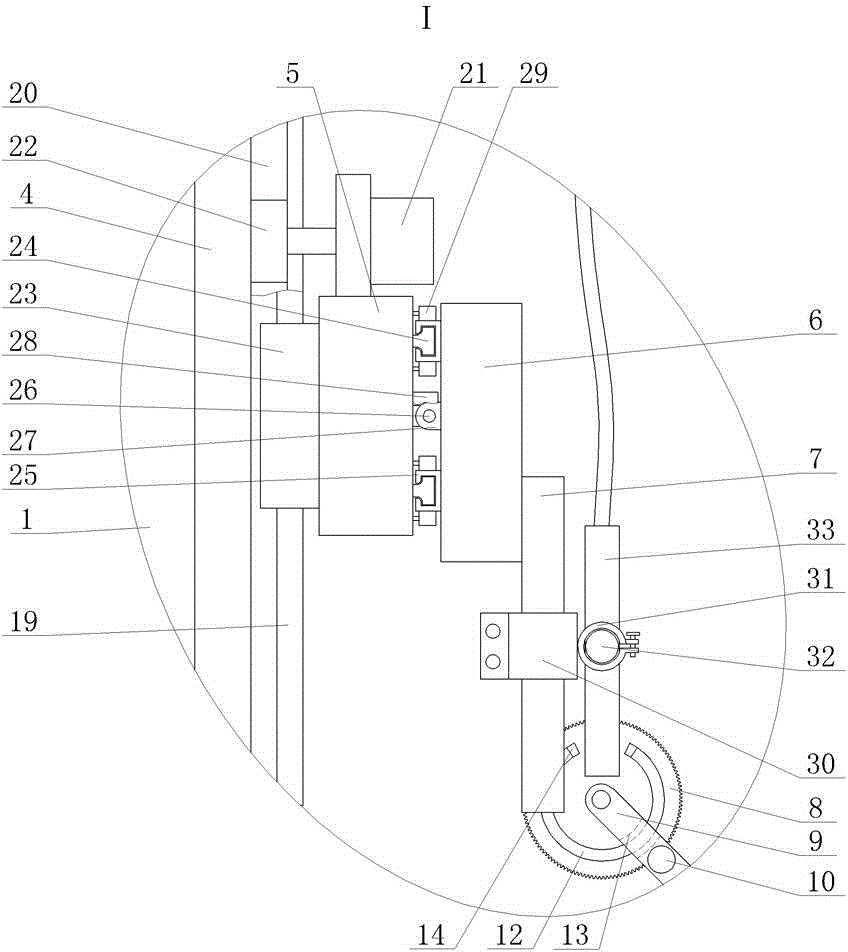

[0009] Heating furnace double-gun automatic welding, such as figure 1 As shown, it includes a frame 1 and a base 2, the base 2 is connected to the bottom plate 15 through a longitudinal movement mechanism, a welding station 3 is arranged on the bottom plate 15, a riser 4 is installed vertically on the frame 1, and the riser 4 is connected to the bottom plate 1 through a vertical movement mechanism. The horizontal plate 5 is connected, and the horizontal plate 5 is respectively connected with two slide plates 6 through a transverse moving mechanism. The welding torch fine-tuning mechanism is arranged on the slide plate 6, and a circular fixed gear 8 is vertically installed on the lower part of the welding torch fine-adjustment mechanism, and the middle part of the fixed gear 8 is articulated with the welding torch 9 , the fixed gear 8 is provided with an arc-shaped first slide rail 12 along the center of the circle, limit blocks 14 are installed at both ends of the first slide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com