Ceramic particle, and filtering element and preparation method thereof

A filter element and ceramic particle technology, which is applied in the direction of dispersed particle filtration, ceramic products, filtration and separation, etc., can solve the problems of reducing thermal stability, increasing thermal expansion coefficient of products, and uneven pore size, so as to increase crack diffusion resistance, Effect of lowering thermal expansion coefficient and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

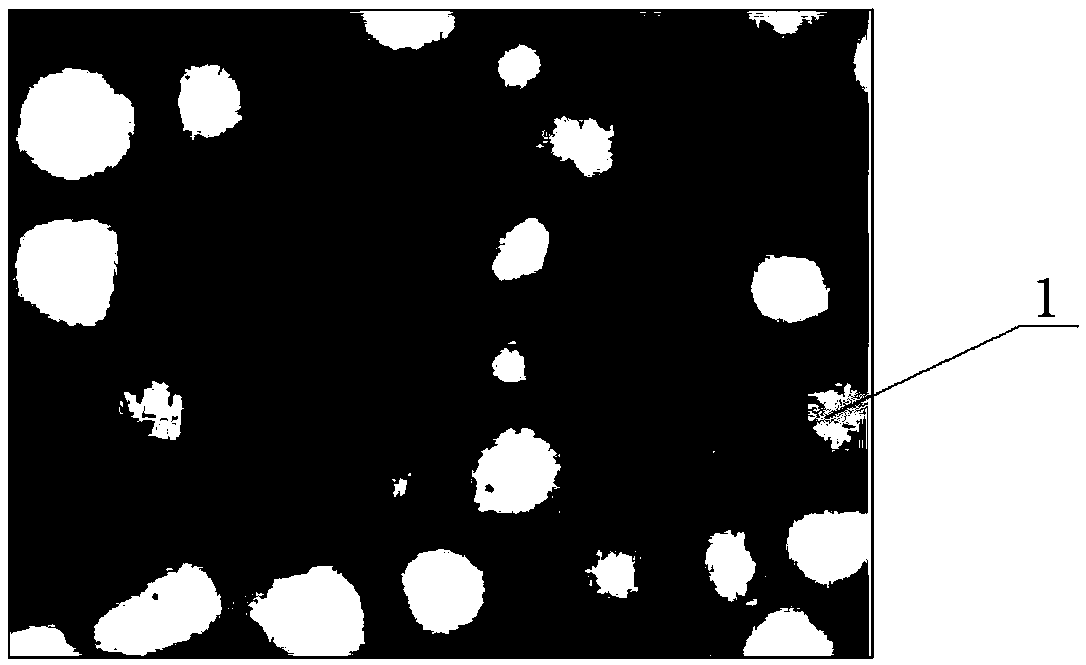

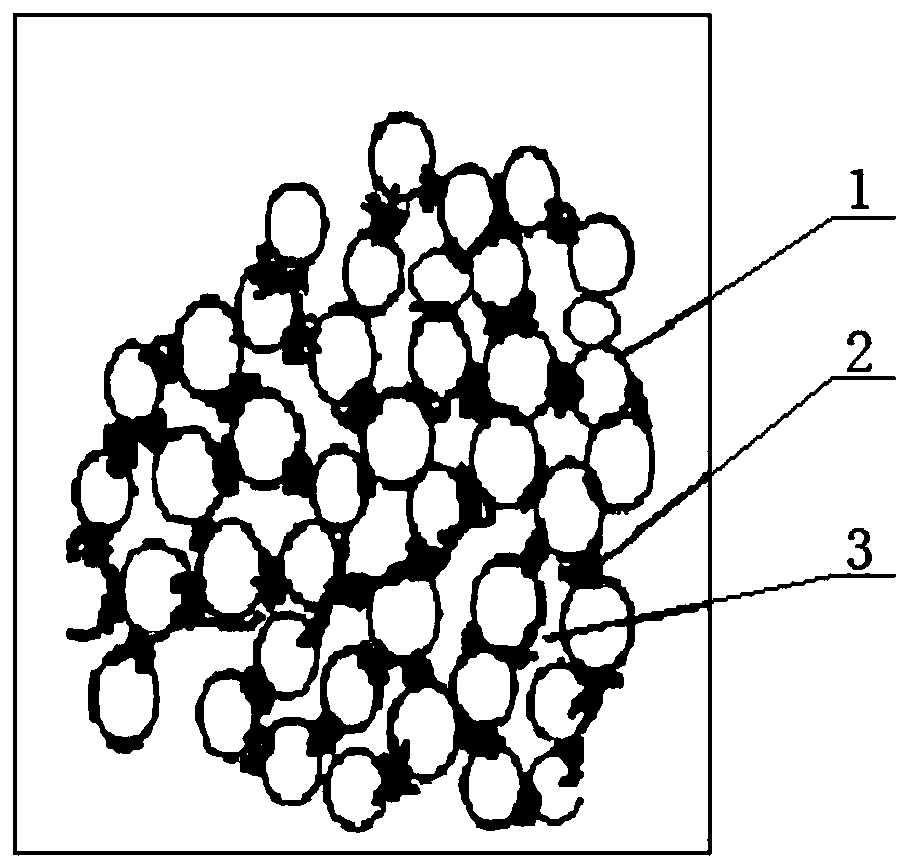

[0043] A kind of ceramic particles, prepared by the following method: kaolin, talc, bauxite, and spodumene are mixed, and the proportion is: 40 parts of kaolin, 35 parts of talc, 15 parts of bauxite, and 3 parts of spodumene. count. The spherical particles whose main crystal phase is cordierite are obtained by ball milling dry powder, rolling molding and firing. The ball milling time is 10 hours, and the ball rolling time is 1 hour. After sieving, spherical particles with a particle size range of 200-250 microns are produced.

[0044] After the particles are sintered at 1280°C, the water absorption rate is 2.5%, and the thermal expansion coefficient is 2.35*10 -6 / °C. Using the spherical particles as aggregates, the prepared ceramic filter element has the advantages of uniform pore size distribution, smooth pores, low filtration resistance, and small thermal expansion coefficient. Compared with ceramic filter elements in the prior art, under the same average pore size, the f...

Embodiment 2

[0046] A kind of ceramic particles, prepared by the following steps: kaolin, talc, bauxite, and spodumene are mixed, and the proportion is: 50 parts of kaolin, 45 parts of talc, 25 parts of bauxite, and 8 parts of spodumene. count. The spherical particles whose main crystal phase is cordierite are obtained by ball milling dry powder, rolling molding and firing. The ball milling time is 10 hr, the ball rolling time is 1.5 hr, and the particle size range of the spherical particles obtained through sieving is 300-500 microns.

[0047] After the particles are sintered at 1370°C, the water absorption rate is 4%, and the thermal expansion coefficient is 2.4*10 -6 / °C. Using the spherical particles as aggregates, the ceramic filter element produced has the advantages of uniform pore size distribution, low filtration resistance, small thermal expansion coefficient, etc., and is especially suitable for high-temperature gas purification. Compared with ceramic filter elements in the p...

Embodiment 3

[0049] Weigh 45kg of kaolin, 40kg of calcined talc, 20kg of high alumina bauxite, and 6kg of spodumene, put them into a ball mill and mill them for 10 hours, pass through a 200-mesh sieve after ball milling, and obtain powder for subsequent use.

[0050] Put the powder into the rolling ball machine and use the rolling ball process to roll until it becomes a ball. The rolling time is 2 hours, then put it in the drying room or drum dryer for drying, sieving, and finally put it in the high-temperature kiln Firing, the firing temperature is 1380° C., and the holding time is 3 hours, to produce spherical ceramic particles whose main crystal phase is cordierite phase, and the particle size is 800-1000 microns. The spherical particles prepared in this embodiment have a water absorption rate of 3.4%, and a crushing rate of the ball under 50KN is less than 8%.

[0051] Among them, spodumene can form a liquid phase at a lower temperature, which can increase the compactness of spherical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com