Paperboard line pressing control system and method thereof

A control system and wire-pressing technology, applied in paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve problems such as difficulty in implementation, increase friction, reduce the possibility of crushing, and reduce non-standard wire-pressing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

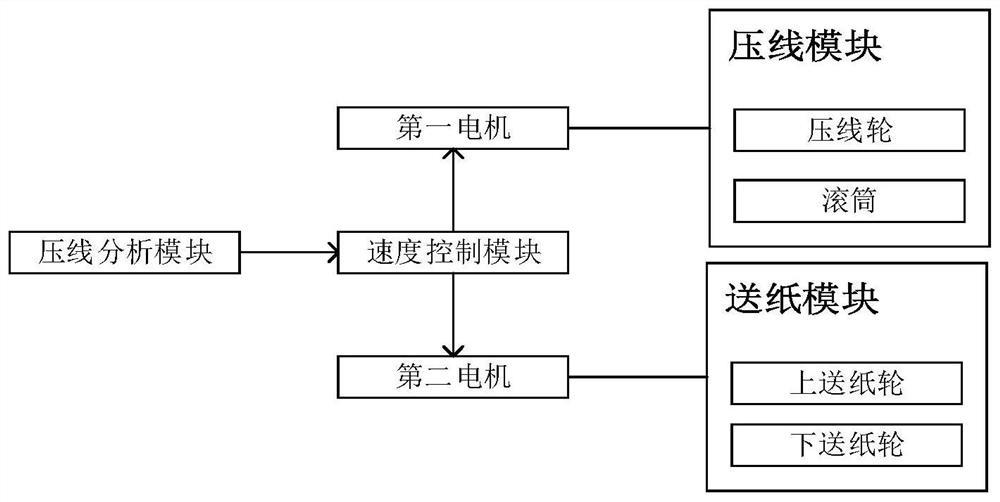

[0028] Embodiment one is basically as attached figure 1 As shown, a cardboard creasing system includes a speed control module, a paper feeding module and a creasing module; the creasing module includes a first motor and a creasing wheel, and the output shaft of the first motor is driven by the creasing wheel connected; the paper feeding module includes a second motor and a paper feeding wheel, the output shaft of the second motor is connected to the paper feeding wheel; the speed control module is used to control the speed of the first motor and the second motor; thus Make the paper feeding wheel feed the paper at a constant speed, and adjust the crimping distance by controlling the speed of the crimping wheel.

[0029] Specifically, the paper feeding wheel includes an upper paper feeding wheel and a lower paper feeding wheel, wherein the upper paper feeding wheel is connected to the output shaft of the second motor, and the upper and lower paper feeding wheels are separated b...

Embodiment 2

[0034] The difference between the second embodiment and the first embodiment is that the second embodiment is a cardboard creasing method using the above-mentioned cardboard creasing system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com