A fuel rod automatic compression spring device

A technology of fuel rods and compression springs, which is applied in the field of automatic fuel rod compression spring devices, can solve problems such as low production efficiency and unstable product quality, and achieve the effects of easy operation, reduced waste rate of compression springs, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

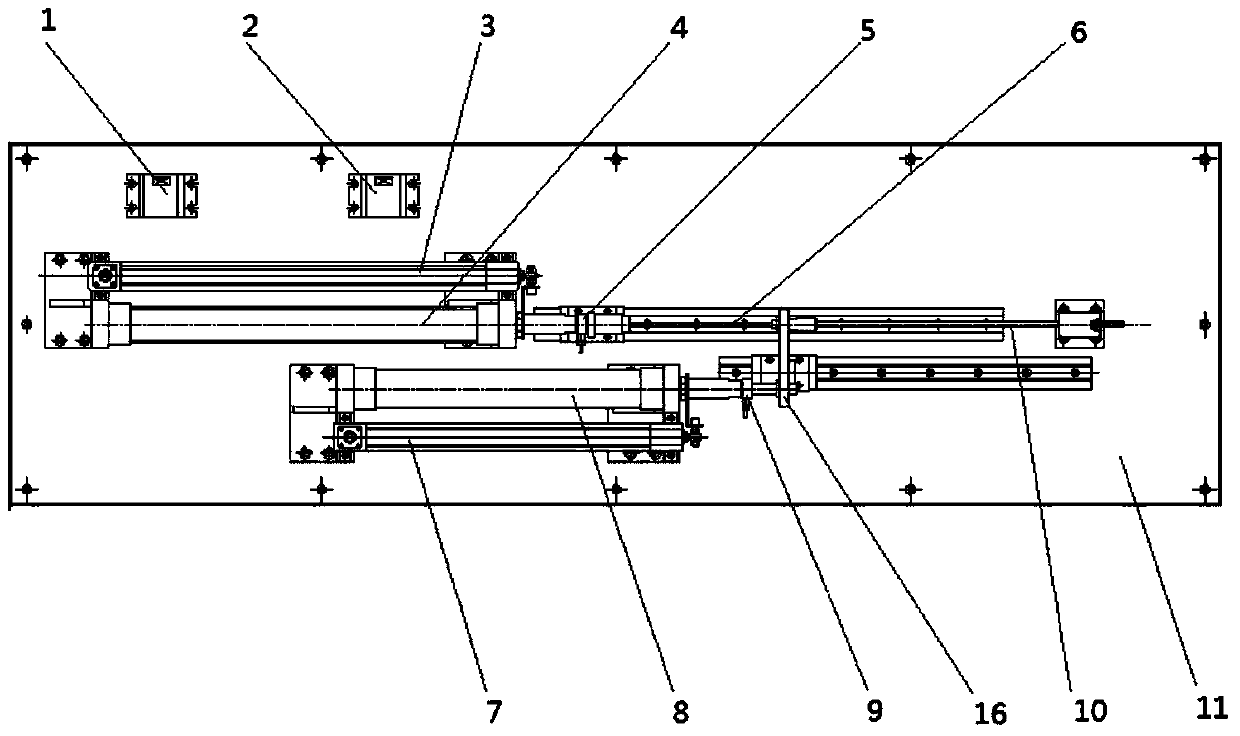

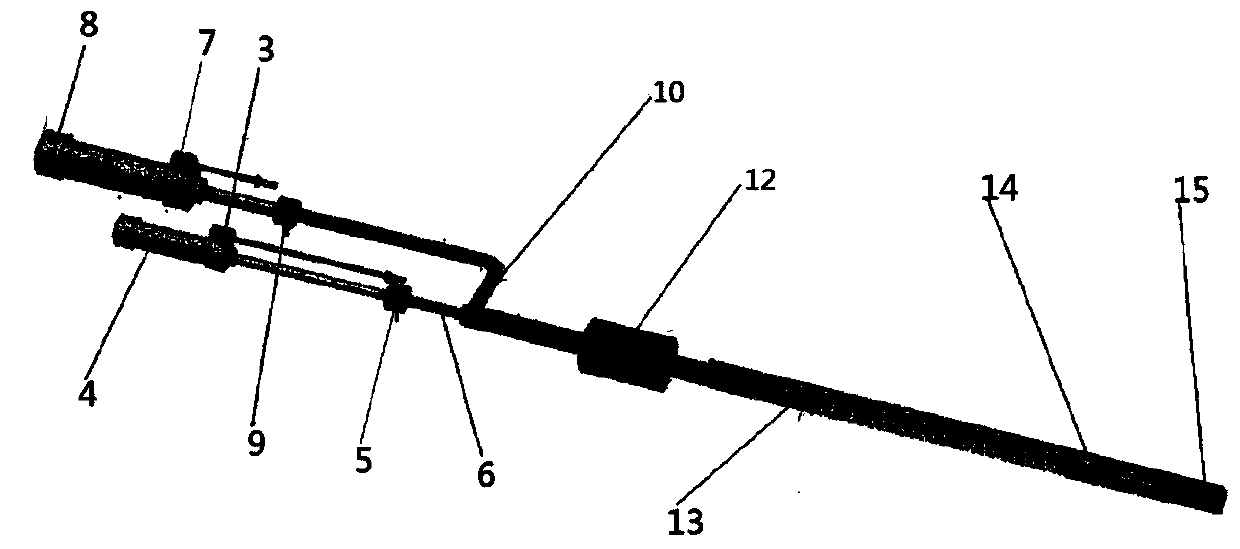

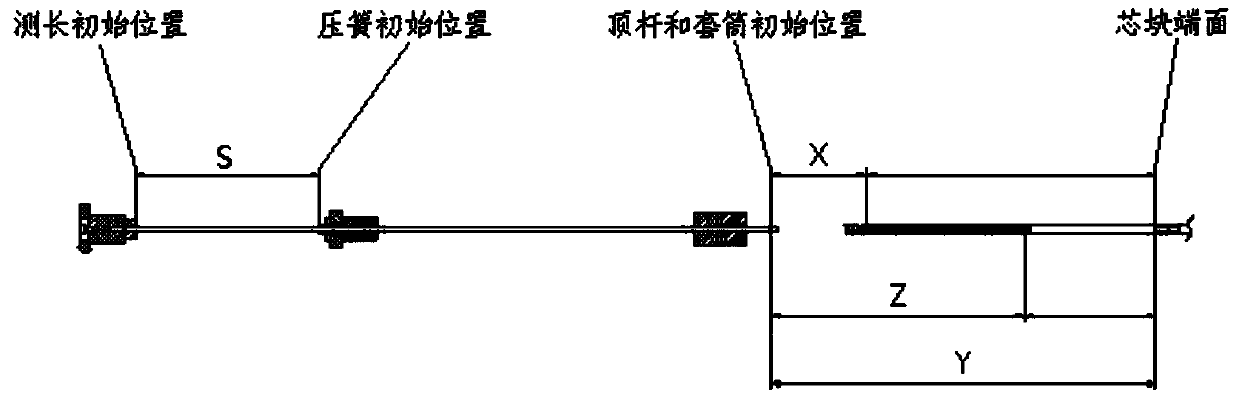

[0036] Such as figure 1 and figure 2 As shown, an automatic fuel rod compression spring device of the present invention includes a length measuring mechanism, a compression spring mechanism, a base plate 11, a guide sleeve 12 and a connecting handle 16;

[0037] The length-measuring mechanism includes a length-measuring electric control valve 1, a length-measuring displacement sensor 3, a length-measuring cylinder 4, a length-measuring pressure sensor 5 and a length-measuring ejector rod 6; 3 is set on the length-measuring cylinder 4 to record the displacement of the length-measuring mandrel 6, and the length-measuring pressure sensor 5 is set on the axis of the length-measuring cylinder 4 to record the force transmitted by the length-measuring mandrel 6 from the core block 14 the pressing force;

[0038] The compression spring mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com