Permanent magnet ECR ion source permanent magnet ring mounting structure and processing method thereof

A technology of installation structure and processing method, which is applied in the direction of plasma, ion beam tube, permanent magnet, etc., can solve the problems of lack of magnetic ring and broken permanent magnetic ring, reduction of magnetic field strength, broken magnetic ring, etc., to simplify the assembly process , reduce the possibility, the installation structure is easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

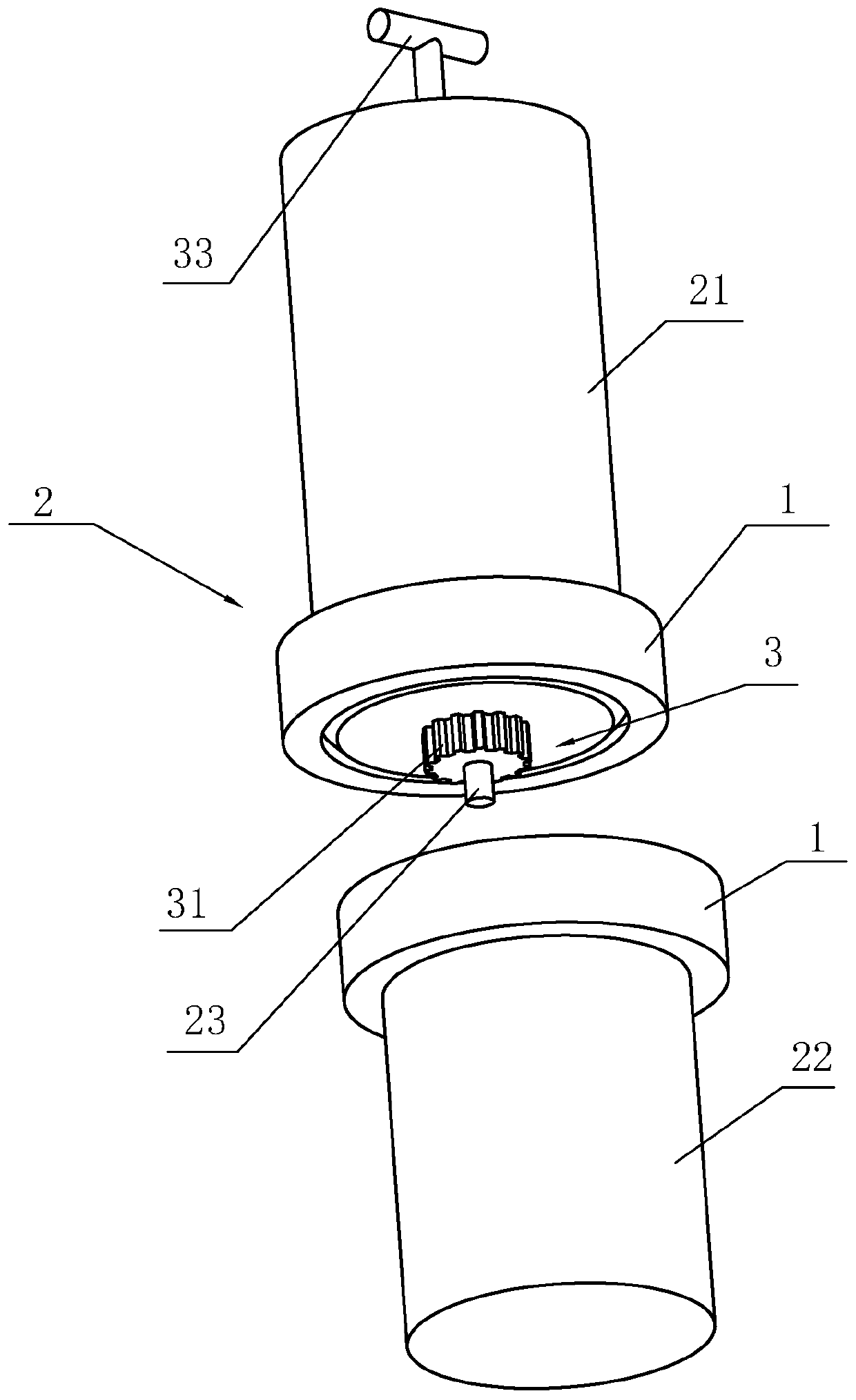

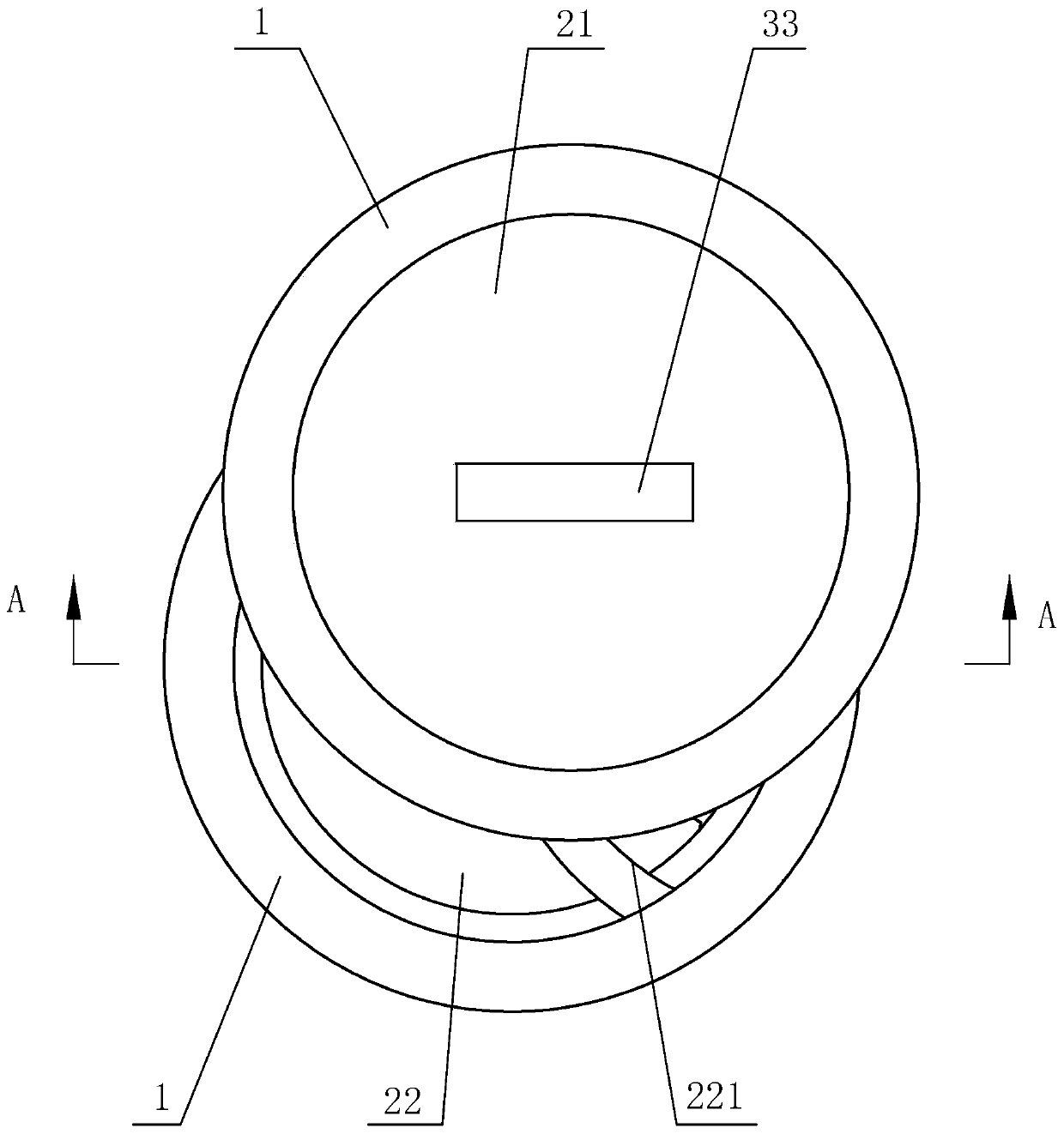

[0041] refer to figure 1 and figure 2, the present invention provides an installation structure of a permanent magnet ECR ion source permanent magnet ring, including a non-magnetic moving bar 21, a static bar 22 and a positioning rod 23, and the outer part of the moving bar 21 and the static bar 22 The diameter is the same as the inner diameter of the permanent magnet ring 1, the positioning rod 23 is arranged at one end of the moving bar 21, the positioning rod 23 is coaxially arranged with the moving bar 21, and an arc-shaped guide passing through the center of the circle is provided on one end of the static bar 22. Groove 221 , the two ends of the guide groove 221 run through the outer surface of the static bar 22 , and the guide groove 221 matches the positioning groove 212 .

[0042] When the permanent magnet ring 1 needs to be assembled, the permanent magnet ring 1 to be assembled is first set on the moving bar 21 and the static bar 22 respectively, and the permanent m...

Embodiment 2

[0051] The invention provides a method for processing the mounting structure of a permanent magnet type ECR ion source permanent magnet ring, comprising the following steps:

[0052] S1, processing two nylon rods with the same outer diameter as the inner diameter of the permanent magnet ring 1 to be installed, the two rods are respectively a moving rod 21 and a static rod 22;

[0053] S2, process the moving bar 21 and the static bar 22:

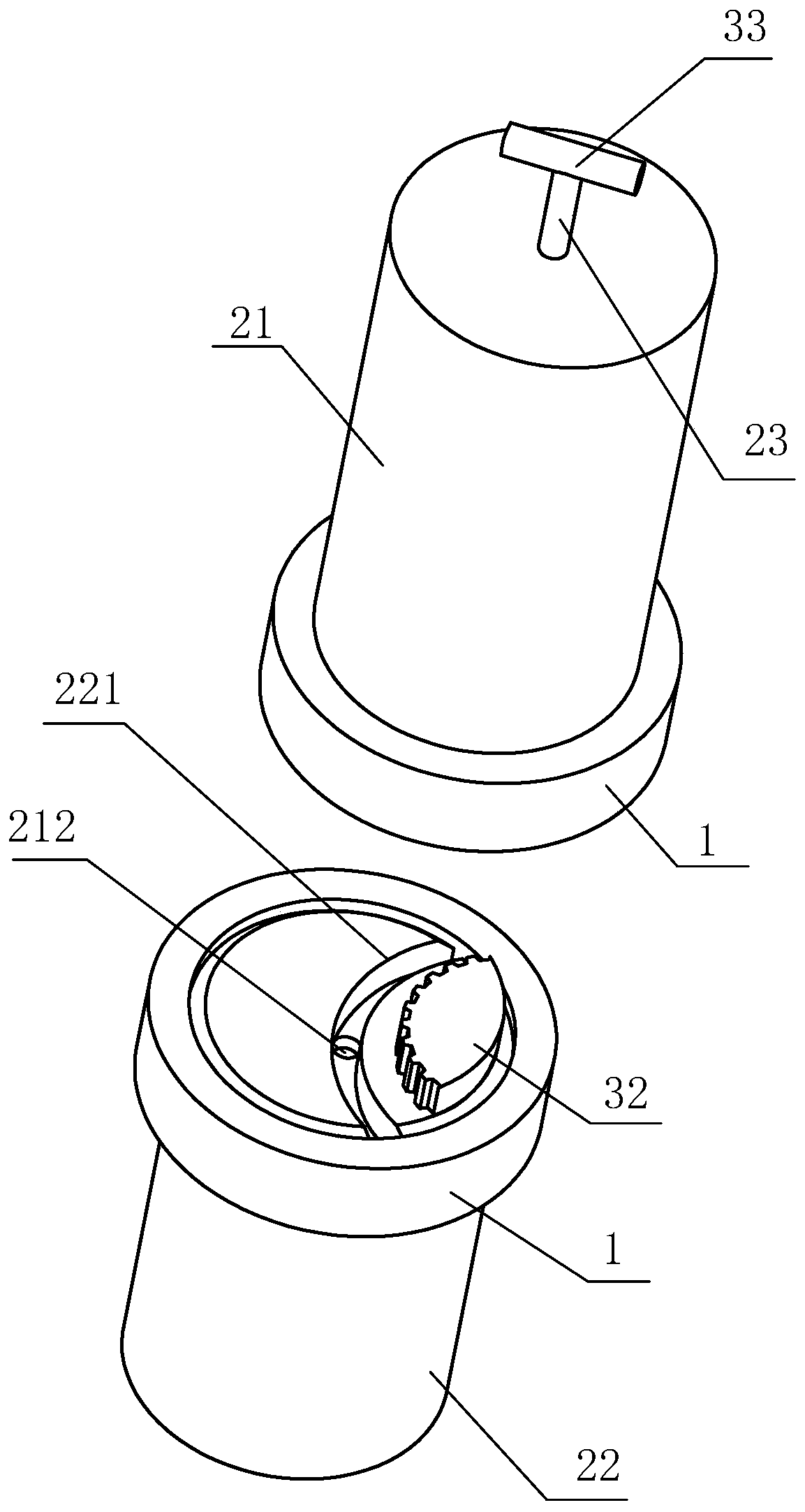

[0054] S21, mill out the installation hole on the end face of the moving bar 21, then insert the positioning rod 23 made of stainless steel into the installation hole, and the two ends of the positioning rod 23 extend to the outside of the moving bar 21;

[0055] S22. Weld the mounting block 31 with a gear-shaped outer surface on the peripheral surface of the positioning rod 23. The welding position of the mounting block 31 is located outside the moving bar 21. The side of the moving bar 21 away from the mounting block 31 is connected to the ...

Embodiment 3

[0062] refer to Figure 5 , the present invention provides an installation structure of a permanent magnet type ECR ion source permanent magnet ring, comprising a moving bar 21 made of nylon, a static bar 22 made of nylon and a positioning rod 23 made of stainless steel, the moving bar 21 and the static The outer diameter of bar stock 22 is all identical with the inner diameter of permanent magnet ring 1, and positioning rod 23 is arranged on one end of moving bar stock 21, and positioning bar 23 is coaxially arranged with moving bar stock 21, and one end surface of static bar stock 22 is provided with a The arc-shaped guide groove 221 passing through the center of the circle, the two ends of the guide groove 221 run through the outer surface of the static bar 22 , the guide groove 221 matches the positioning groove 212 .

[0063] When the permanent magnet ring 1 needs to be assembled, the permanent magnet ring 1 to be assembled is first set on the moving bar 21 and the static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com