Continuous sealing machine transmission

A transmission device and sealing machine technology, applied in the field of packaging bag sealing, can solve the problems of difficulty in achieving continuous sealing of packaging bags and low sealing efficiency of packaging bags, and achieve the effects of reducing risks and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

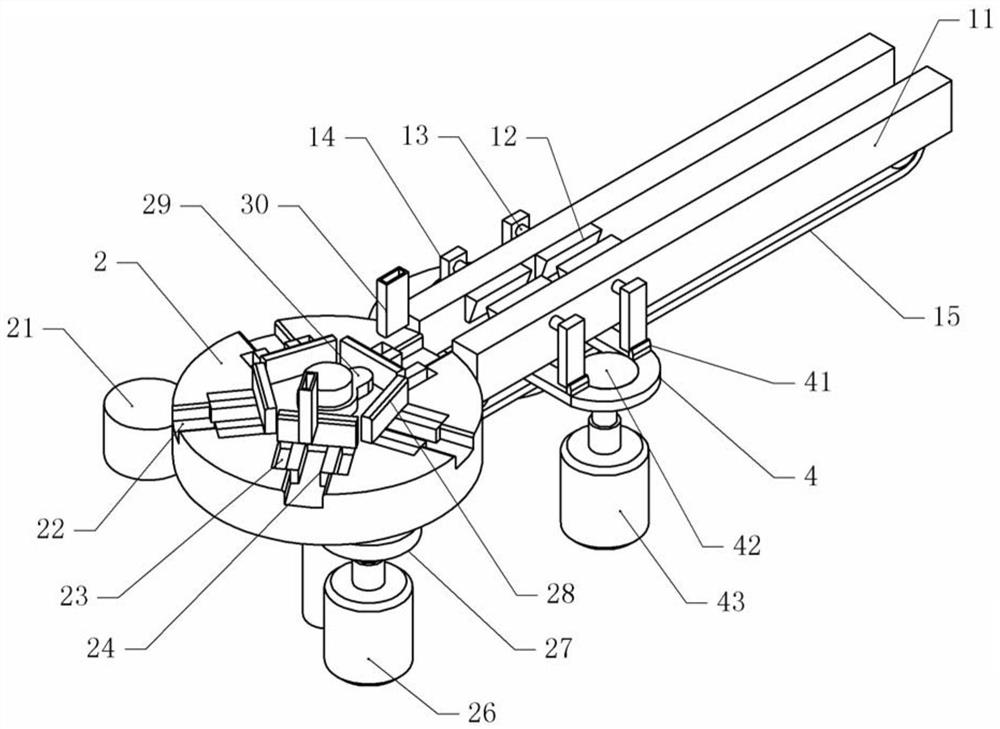

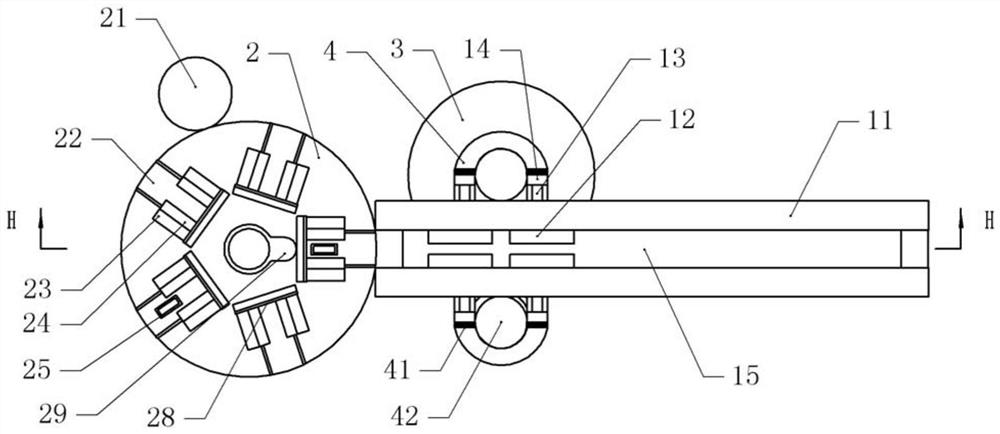

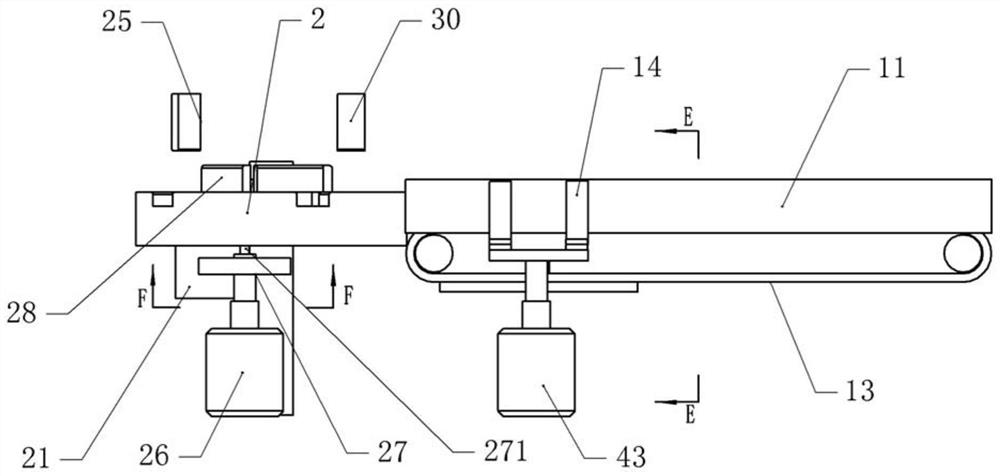

[0038] basically as attached figure 1 , attached figure 2 and attached image 3 Shown: a transmission device for a continuous sealing machine, including a frame, a rotating shaft is fixedly installed with bolts on the frame, the upper part of the rotating shaft is rotatably connected with an operating table 2 with a circular longitudinal section, and the operating table 2 is opened along its axial direction. There are several workstations 23 . The workstations 23 are communicated with guide grooves 22 , and the width of the guide grooves 22 is smaller than the width of the workstations 23 . Hollow clamping plates 24 are fixed with screws on both sides in the station 23, Figure 5As shown, several air holes 241 are opened on the clamping plate 24 , the negative pressure pump 21 is bolted on the operating table 2 , and the negative pressure pump 21 communicates with an air pipe that communicates with the clamping plate 24 . A push plate 28 that is horizontally slidably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com