Alternation type foam storing and proportion mixer

A proportional mixing device and proportional mixer technology, which is applied in fire rescue and other directions, can solve the problems of long production cycle, difficult measurement and control accuracy, long design and production cycle, etc., to achieve reliable and convenient manufacturing, installation and debugging, and overcome accurate It is not easy to grasp the degree and the effect of reducing the probability of easy crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

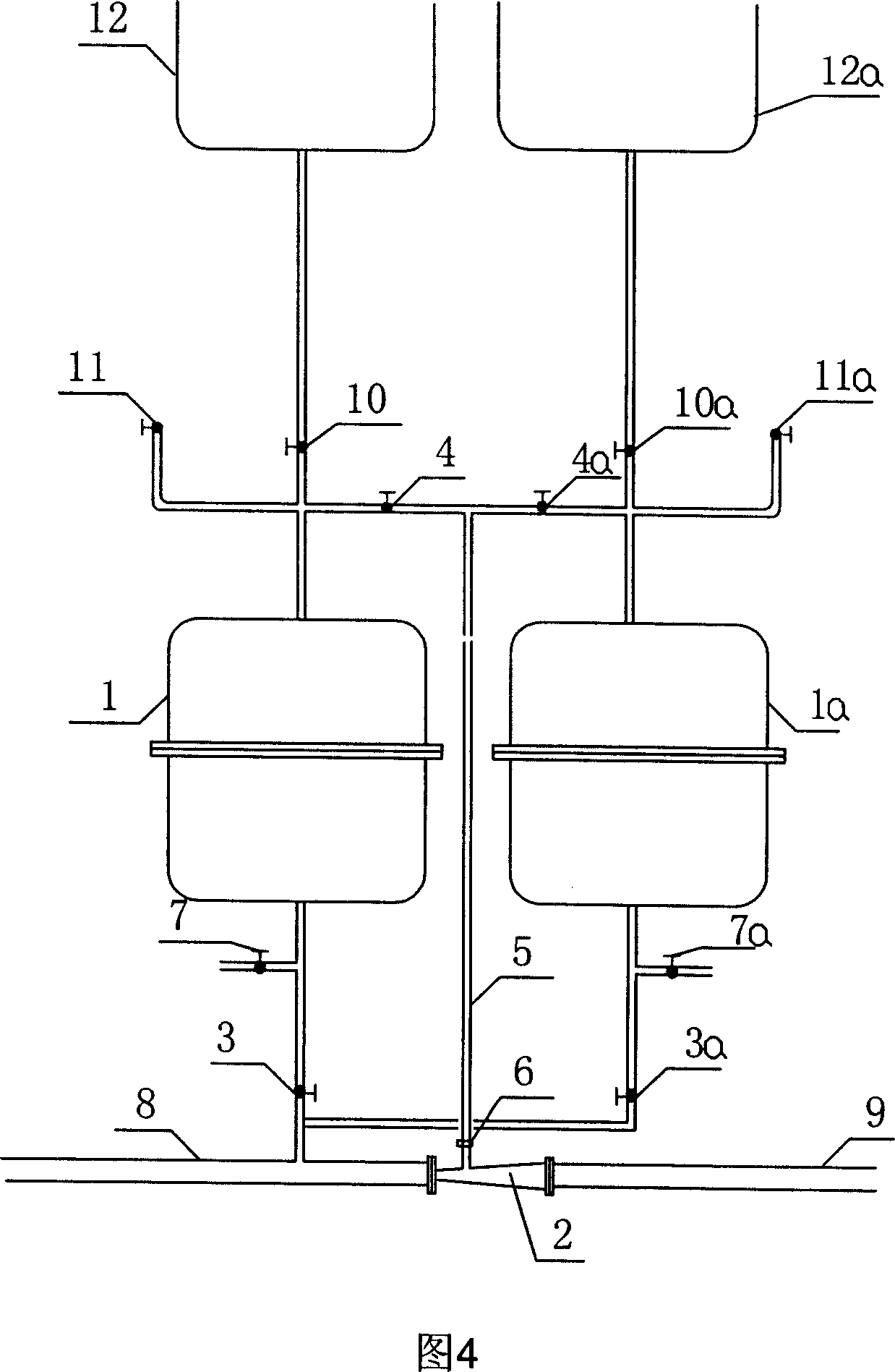

[0021] Figure 3 schematically shows one embodiment of the foam storage and proportional mixing device of the present invention. In the embodiment shown in Figure 3, the foam storage and proportional mixing device includes: foam storage container 12, pressure foam tank 1, 1a, proportional mixer 2, water inlet valve 3, 3a, drain valve 7, 7a, liquid outlet Valve 4, 4a, water supply pipe 8, filling valve 10, 10a, air release valve 11, 11a, control unit (not shown). As shown in FIG. 3 , the foam storage container 12 is connected with the pressure foam tanks 1, 1a, and is used for injecting foam liquid into the pressure foam tanks 1, 1a. The pressure foam tanks 1, 1a are connected to the proportional mixer 2 through a pipeline 5, and are used to output foam liquid to the proportional mixer. A water supply pipe 8 is connected to the pressure foam tanks 1, 1a and the proportional mixer 2 for supplying them with water.

[0022] A kind of alternate foam storage and proportional mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com