Small-deformation wind tunnel train balance

A technology of strain balance and small deformation, which is applied in the direction of measuring devices, instruments, aerodynamic tests, etc., can solve the problems of insufficient balance rigidity and bearing capacity, and insufficient utilization of balance design, so as to reduce the difficulty of design and benefit balance components Structure and layout optimization design, the effect of enlarging the balance diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

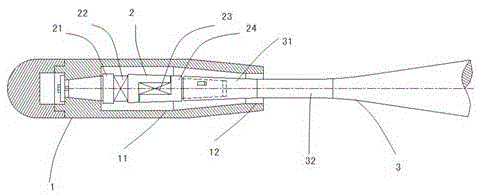

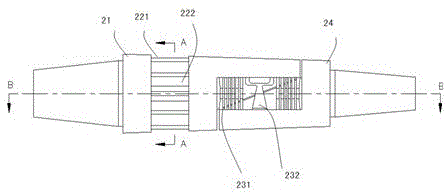

[0025] figure 1 It is a schematic diagram of the assembly of a small deformation wind tunnel strain balance of the present invention. A strain balance in a small deformation wind tunnel according to the present invention mainly includes a rod-type balance and a support rod, and the rod-type balance and the support rod are tightened through a tapered surface and a wedge, and the cone is located inside the inner cavity of the model. The maximum diameter of the rod-type balance element is slightly smaller than the minimum diameter of the inner cavity at the tail of the model, which facilitates the installation and disassembly of the model while increasing the diameter of the rod-type balance element. The minimum diameter of the tapered part of the rod-type balance element is greater than the diameter of the straight section such as the support rod, and the value is calculated through the constraints of the balance and the taper at the front end of the support rod.

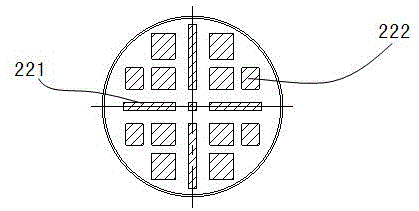

[0026] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com