Casting method of gear

A colloidal and liquid binder technology, which can be used in casting molding equipment, casting molds, casting mold components, etc., and can solve problems such as low production efficiency, high labor intensity, and waste of human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

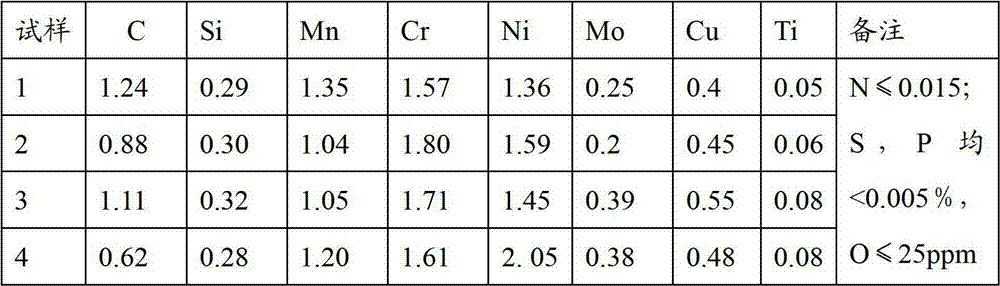

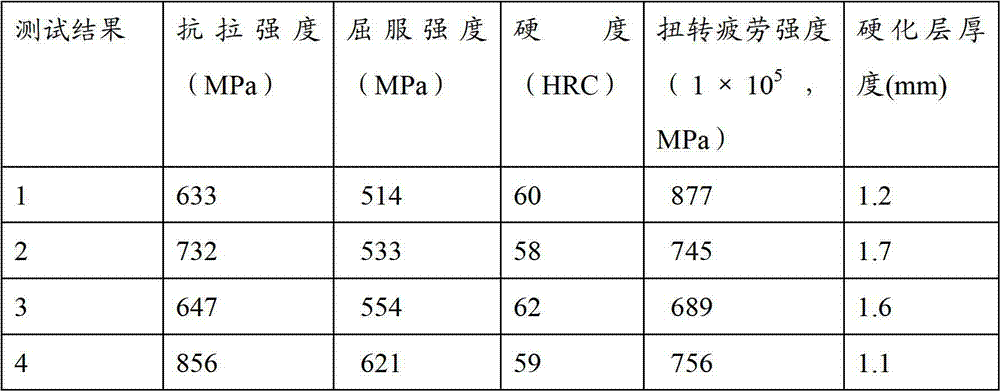

Embodiment 1

[0031] Follow the steps below to cast a gear sample,:

[0032] 1) Dip the preformed fusible model into a slurry composed of ceramic particles and colloidal liquid binder, thereby forming a coating on the model and spray drying; the ceramic particles can be silicon carbide, silicon nitride Or tungsten carbide, the size of the particles is 20-50 μm; the colloidal liquid binder is polyacrylamide; the weight ratio of ceramic particles and colloidal liquid binder in the slurry composed of ceramic particles and colloidal liquid binder is 1 :0.1;

[0033] Wherein, step 1) is repeated 3 times;

[0034] 2) Apply a slurry composed of refractory material particles and colloidal liquid binder to the coating in step 1), and spray dry; wherein, the refractory material is silica; the refractory material particles and glue The weight ratio of solidified material is 100:5;

[0035] Wherein, step 2) is repeated twice;

[0036] 3) 200°C for 1 hour to melt the mold, and bake the shell;

[00...

Embodiment 2

[0043] Follow the steps below to cast a gear sample,:

[0044] 1) Dip the preformed fusible model into a slurry composed of ceramic particles and a colloidal liquid binder, thereby forming a coating on the model and spray drying; the ceramic particles are silicon nitride and tungsten carbide ( The weight ratio is 10:1), the particle size is 100-200μm; the colloidal liquid binder is polyacrylate; ceramic particles and colloidal liquid binder in the slurry composed of ceramic particles and colloidal liquid binder The weight ratio is 1:10;

[0045] Wherein, step 1) is repeated 5 times;

[0046] 2) Apply a slurry consisting of refractory particles and colloidal liquid binder to the coating in step 1), and spray dry; wherein, the refractory material is magnesium oxide; the refractory particles and gelled The weight ratio of forming materials is 100:10;

[0047] Wherein, step 2) is repeated 3 times;

[0048] 3) Heat at 400°C for 1 hour to melt the mold and bake the shell;

[00...

Embodiment 3

[0053] Follow the steps below to cast a gear sample,:

[0054] 1) Dip the preformed fusible model into a slurry composed of ceramic particles and a colloidal liquid binder, thereby forming a coating on the model and spray drying; the ceramic particles are tungsten carbide, and the size of the particles is 50-100 μm; the colloidal liquid binder is a mixture of polyacrylamide and polyacrylate; the weight ratio of ceramic particles and colloidal liquid binder in the slurry composed of ceramic particles and colloidal liquid binder is 1:0.5 ;

[0055] Wherein, step 1) is repeated 3 times;

[0056] 2) Apply a slurry composed of refractory particles and colloidal liquid binder to the coating in step 1), and spray dry; wherein, the refractory material is alumina; the refractory particles and gelled The weight ratio of forming materials is 100:1;

[0057] Wherein, step 2) is repeated twice;

[0058] 3) Heat at 300°C for 2 hours to melt the mold, and bake the shell;

[0059]4) Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com