Water cooling copper crucible directional freezing method for superhigh-temperature Nb-Si alloy

A technology of water-cooled copper crucible and directional solidification, which is applied in self-solidification, chemical instruments and methods, crystal growth, etc., can solve the problems of poor comprehensive physical and mechanical properties of alloys, difficult adjustment of microstructure, low efficiency of directional solidification, etc., and achieve excellent High temperature strength, high directional solidification efficiency, and the effect of reducing processing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

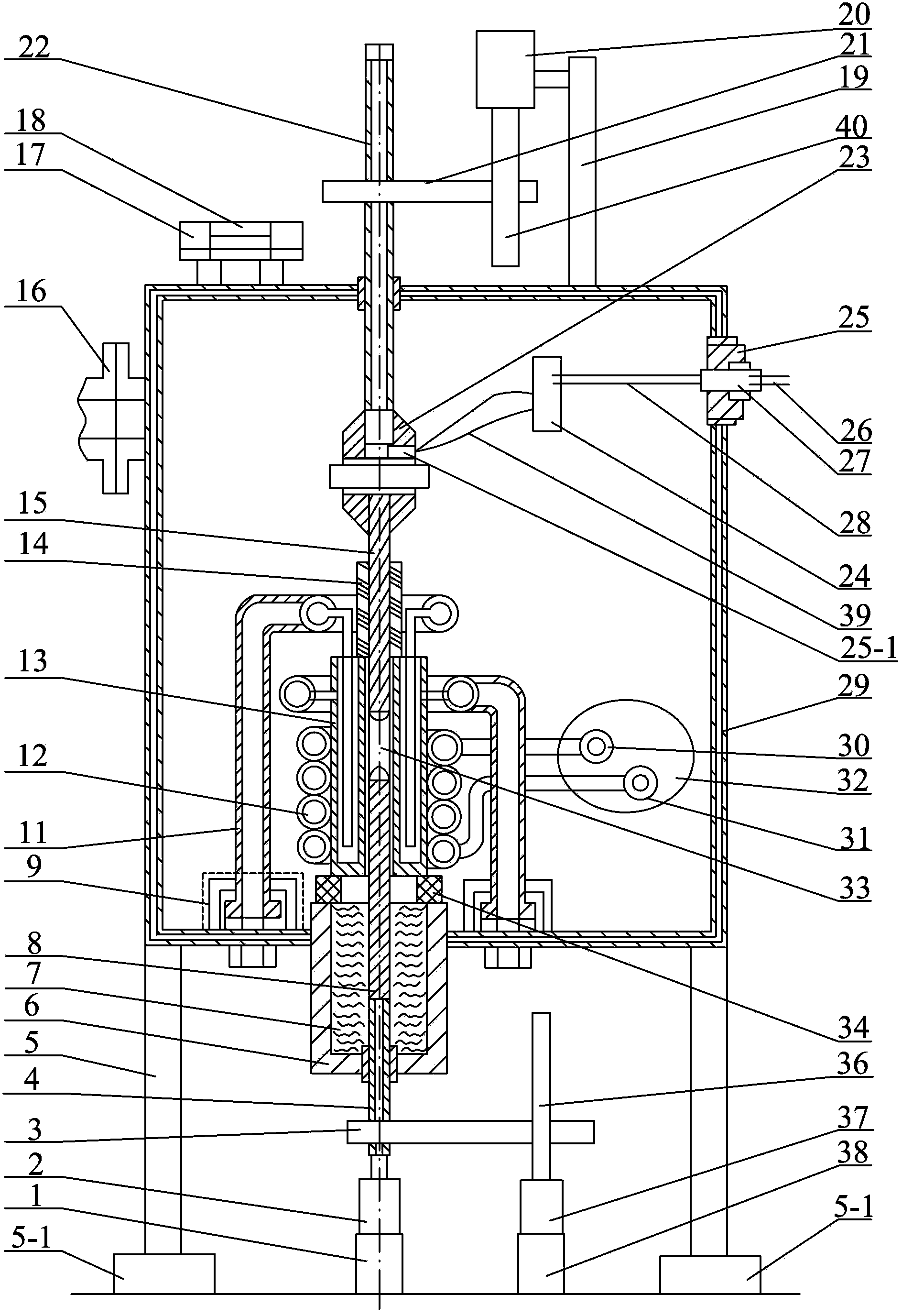

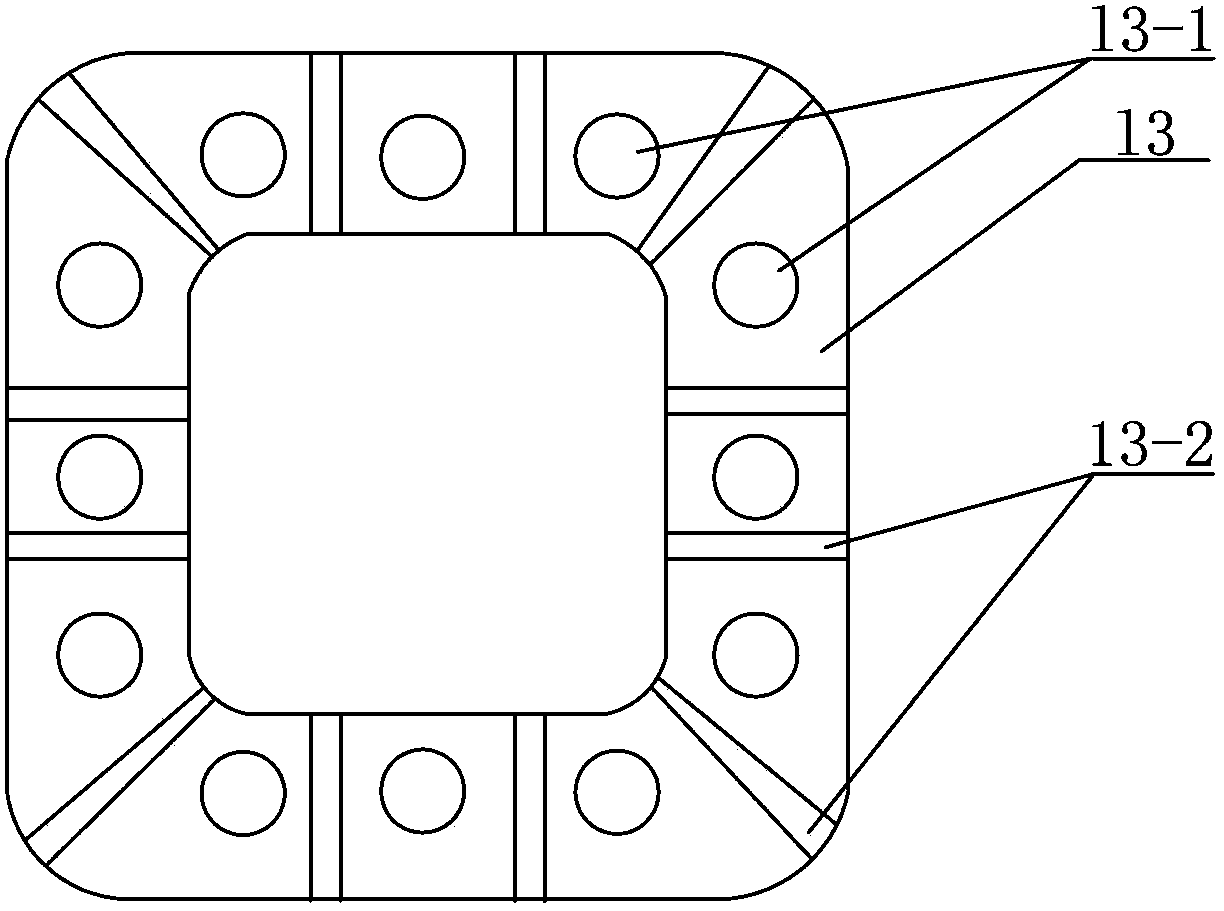

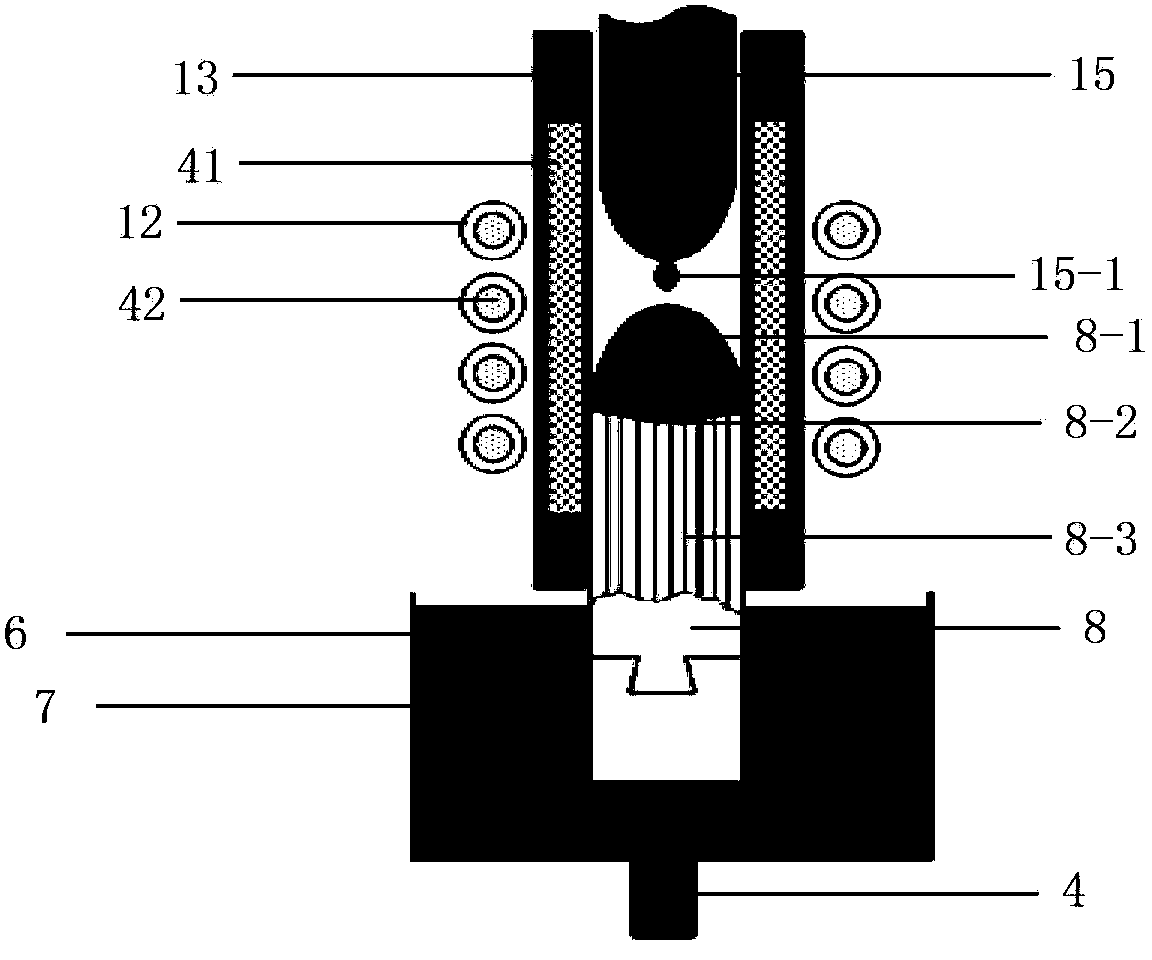

[0018] Specific implementation mode one: combine figure 1 and figure 2To illustrate this embodiment, the specific steps of a water-cooled copper crucible directional solidification method for an ultra-high temperature Nb-Si-based alloy described in this embodiment are:

[0019] Step 1. Place the feeding rod 15, the base material 8, the water-cooled copper crucible 13 and the induction coil 12 in the furnace body 29 of the cold crucible electromagnetic precise forming and directional solidification device. The furnace body 29 is provided with the feeding rod 15 and the bottom Material 8, feeding rod 15 and bottom material 8 are provided with a water-cooled copper crucible 13, and the exterior of the water-cooled copper crucible 13 is provided with an induction coil 12, and the number of turns of the induction coil 12 is 3 to 5 turns;

[0020] Step 2, in the body of furnace 29, first vacuumize to 10 -3 ~1Pa, back flush with argon to 280~320Pa;

[0021] Step 3: After the feed...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the frequency of the single-phase alternating current fed in step 3 is 20 kHz. Such setting, such setting, can excite the alternating magnetic field and diffuse to the inside through the water-cooled copper crucible wall to generate the hot zone required for the processing process and meet the preparation requirements of directional solidification of Nb-Si-based alloys. Others are the same as in Embodiment 1

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the frequency of the single-phase alternating current fed in Step 3 is 50 kHz. With such arrangement, the alternating magnetic field can be excited and spread to the inside through the wall of the water-cooled copper crucible to generate the hot zone required for the processing process and meet the preparation requirements of directional solidification of Nb-Si-based alloys. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com