Processing-control device, laser processing device and laser processing system

A technology for controlling devices and processing positions, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as poor processing and achieve the effect of reducing poor processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

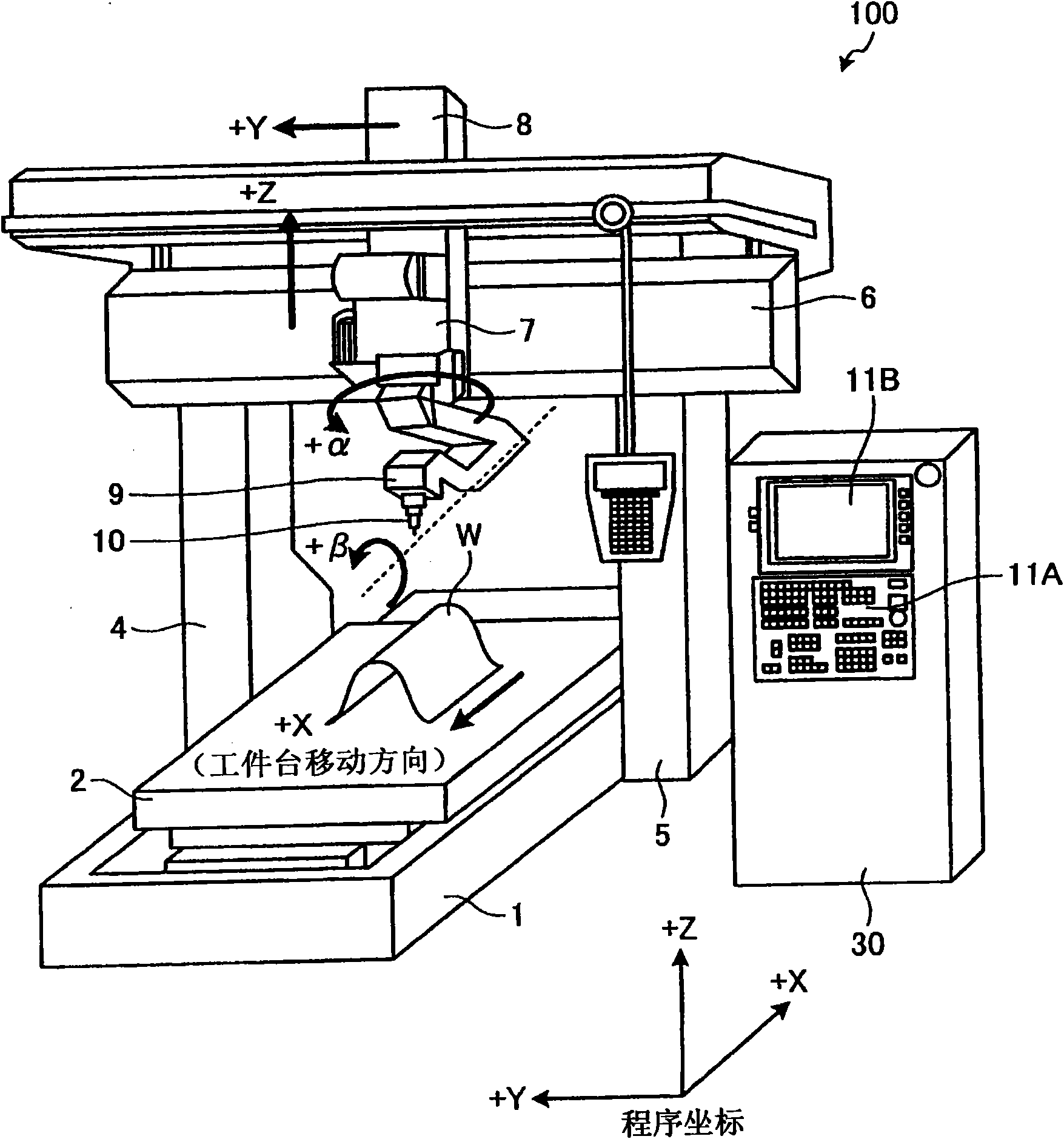

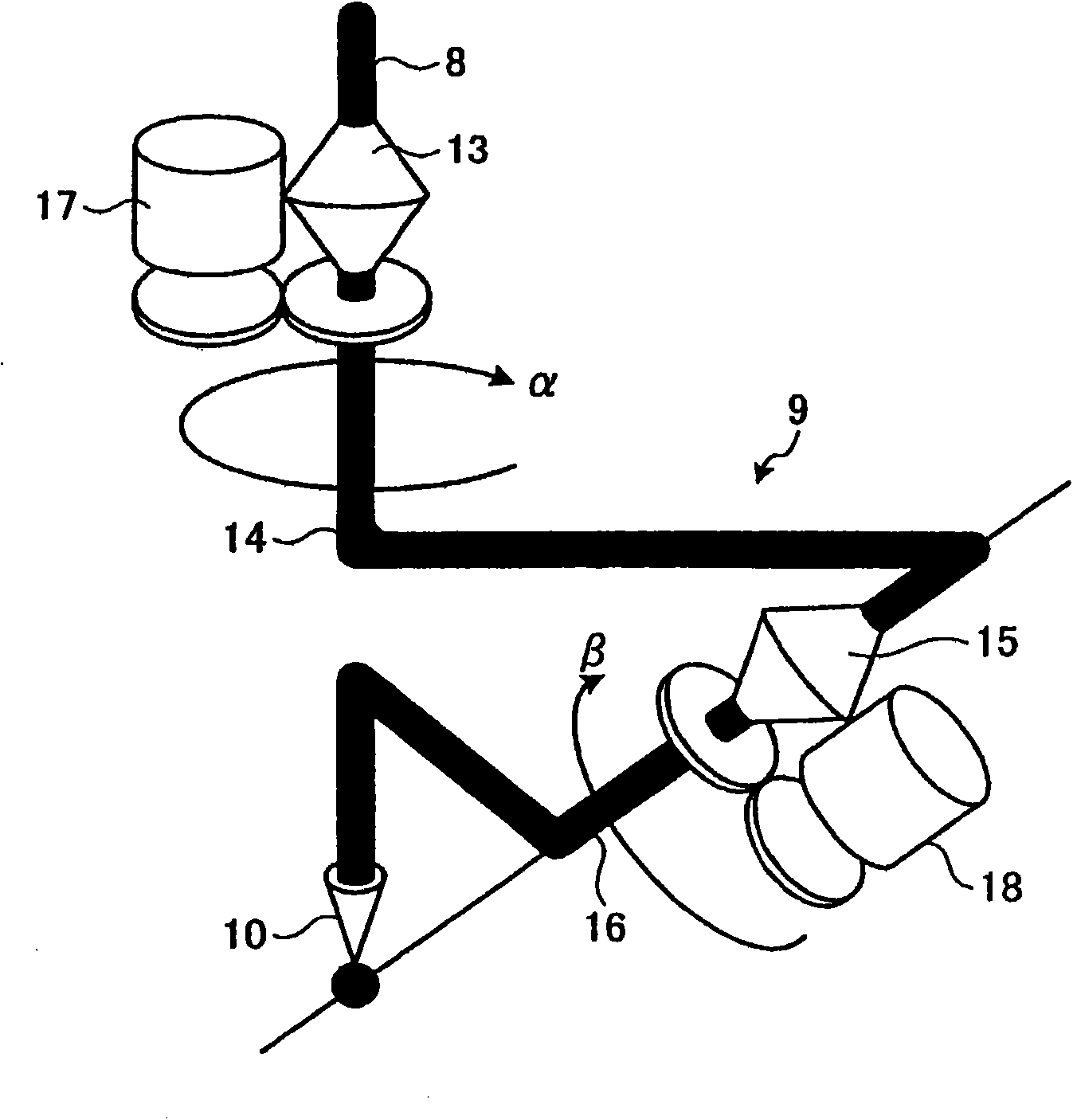

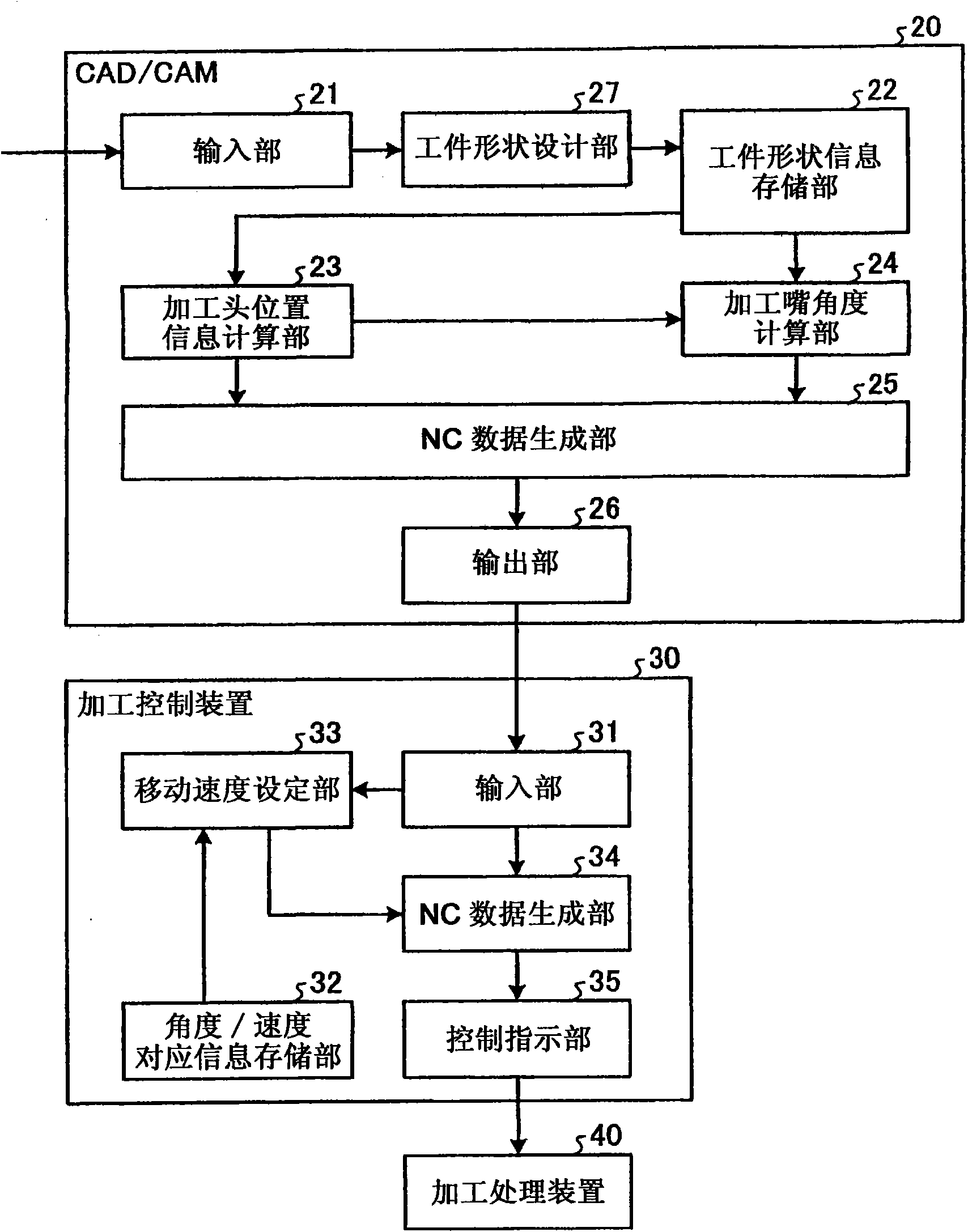

[0022] figure 1 It is a configuration diagram showing a three-dimensional laser processing machine according to an embodiment of the present invention. exist figure 1 In , a configuration example of the three-dimensional laser processing machine 100 is shown in a perspective view. The three-dimensional laser processing machine 100 sets the movement of the machining head 9 at each indicated point based on NC data 101A described later and the angle of the workpiece W relative to the machining nozzle 10 at each indicated point (the machining nozzle angle θ described later). speed (moving speed d described later). Then, three-dimensional laser processing of the workpiece W is performed while moving the processing head 9 at the moving speed d set for each indicated point.

[0023] The three-dimensional laser processing machine 100 has: a workpiece table 2, which can be moved along the X-axis direction and is arranged on the base 1; a transverse guide rail 6, which is horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com