Electromagnetic braking translation-type rolling plate clamp

An electromagnetic braking and translational technology, which is applied in the direction of transmission devices, friction transmission devices, load suspension components, etc., can solve the problems of processing and assembly errors of supporting beam processing parts, clamp arm protection devices that cannot be moved by suspended objects at the same time, Problems such as inaccurate reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

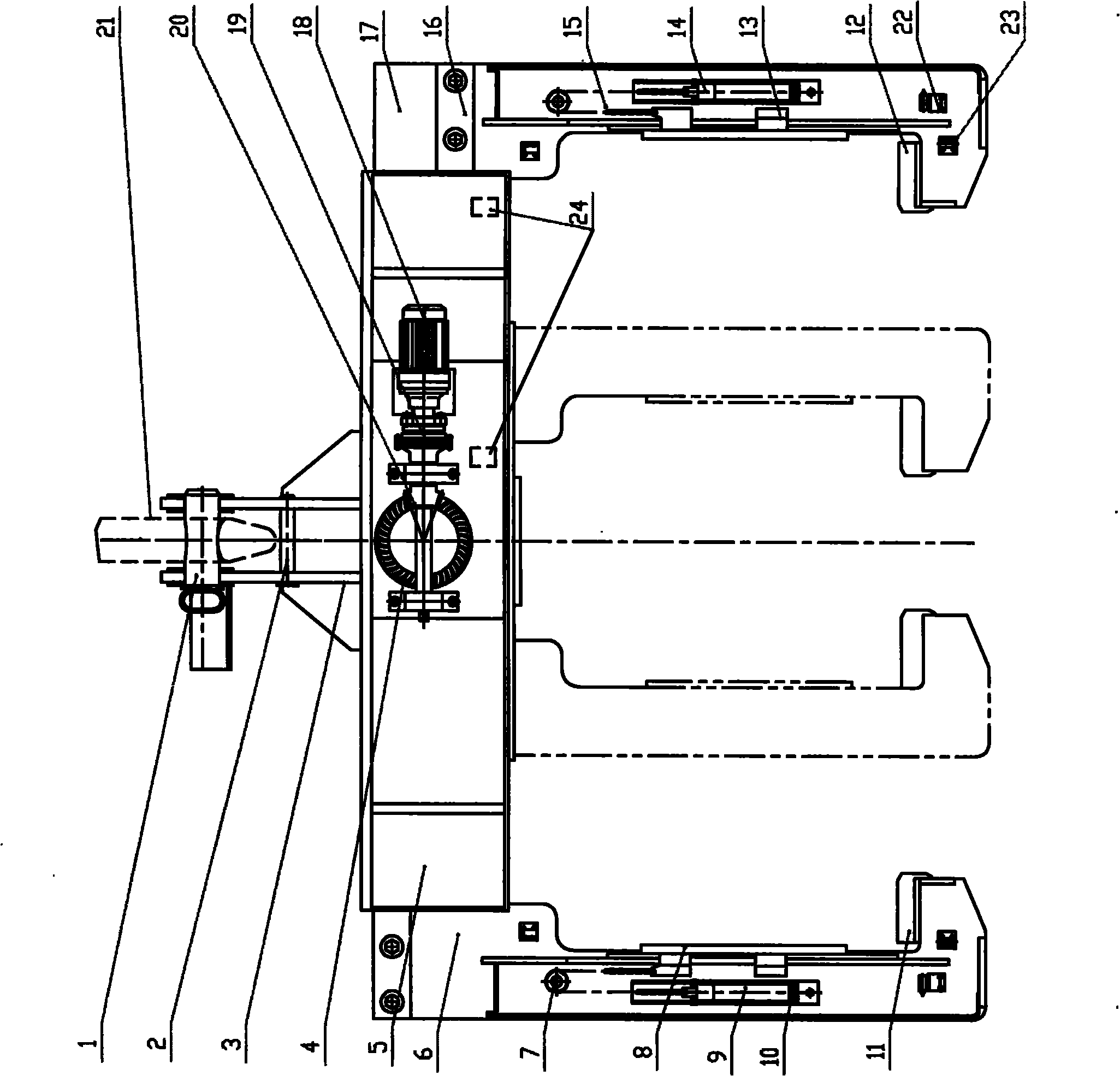

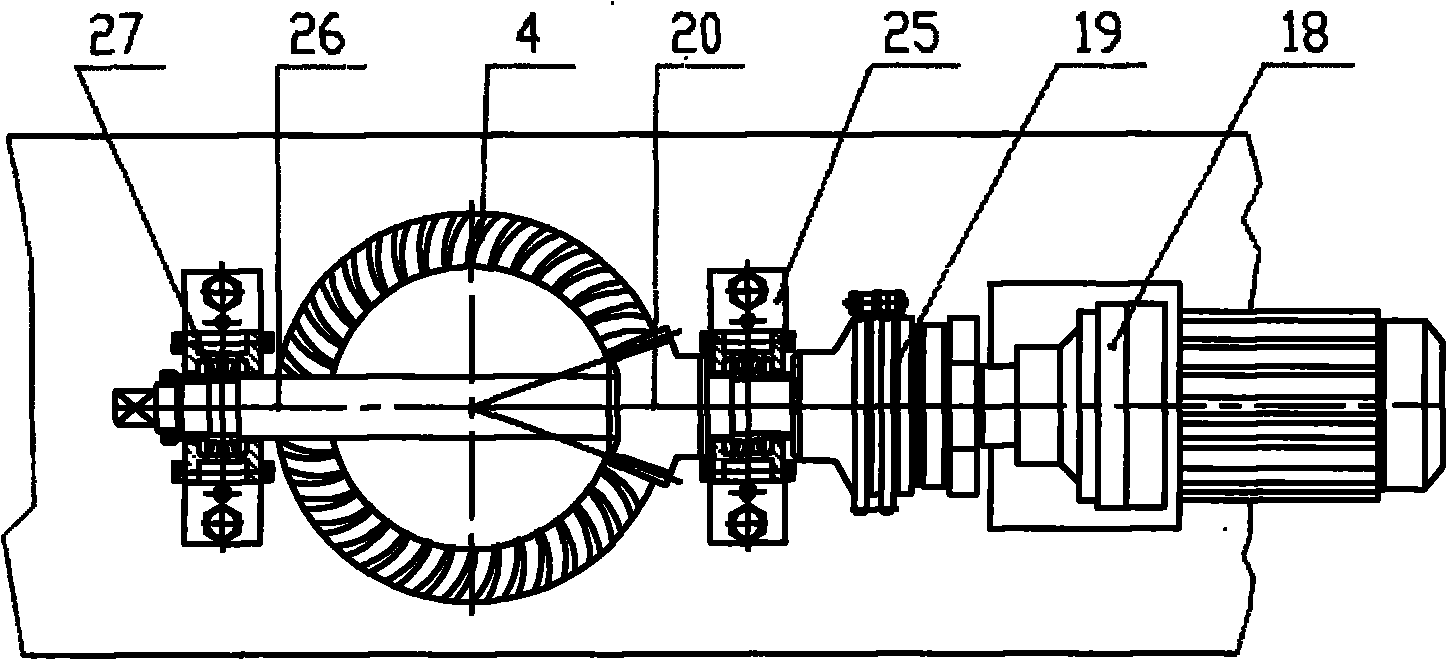

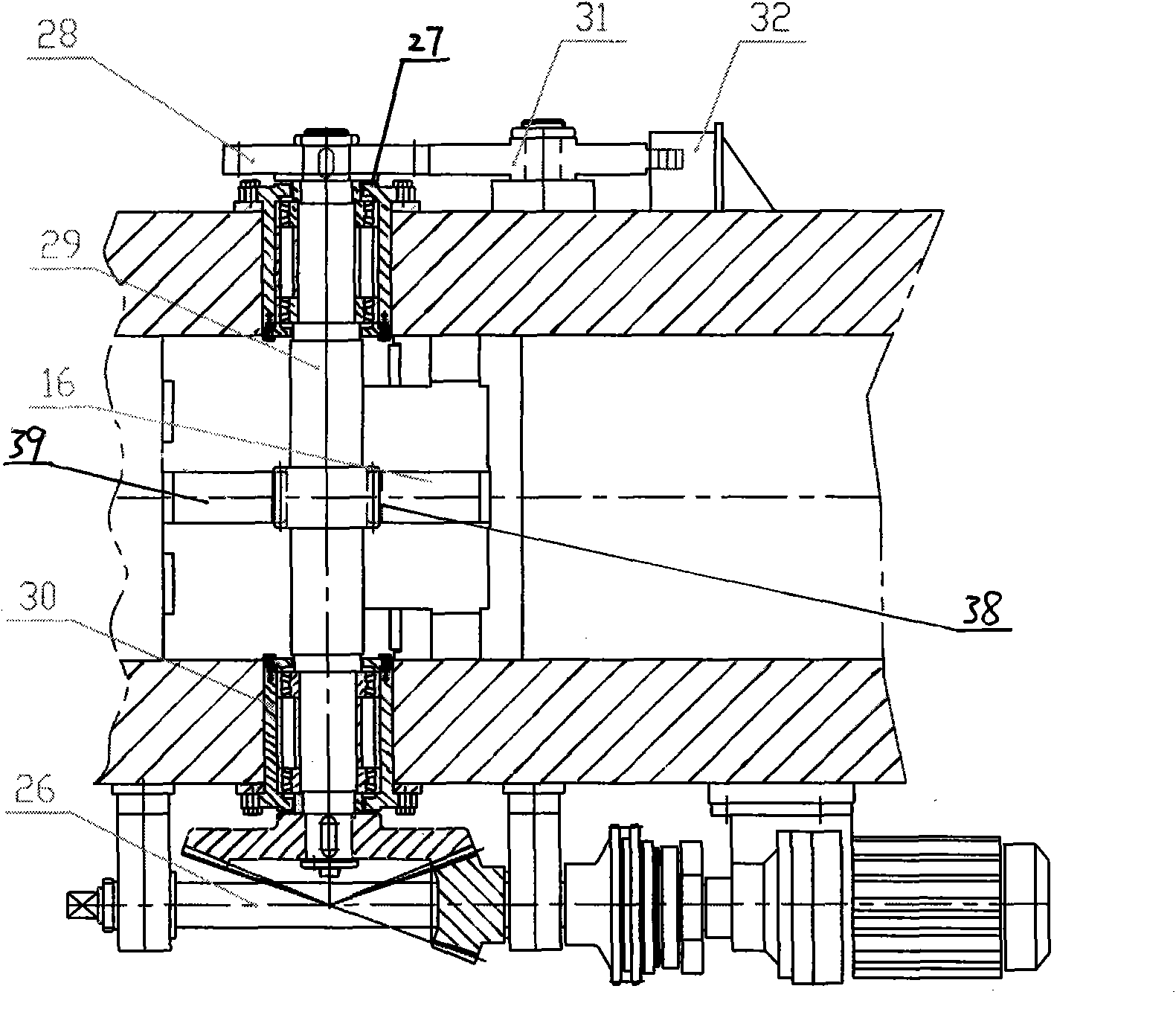

[0017] Such as figure 1 with figure 2 As shown, this embodiment includes a lifting device, a driving device, an electromagnetic braking device, a support beam, left and right clamp arms, a protection device, a protection device for the clamp arms and an electrical system.

[0018] Hoisting device is installed on the top of supporting crossbeam 5, and it comprises hanging shaft 1, hanging shaft bracket, lifting bracket 3 and anti-off shaft 2. The lifting frame 3 that there are two hanging lugs on the upper end is connected with the support beam 5 with the anti-off shaft 2, and the hanging shaft bracket is installed on one side of the lifting frame 3. When not hoisting, the suspension shaft 1 is positioned in the suspension shaft bracket, and during hoisting, the suspension shaft 1 moves forward and is placed in two lugs and the suspension hook 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com