Martensite-granular bainite plastic die steel and manufacturing method thereof

A technology of plastic mold steel and granular bainite, which is applied in the field of iron and steel material manufacturing, can solve the problems of failure to form plastic steel series and lagging development of plastic mold steel, and achieve low preparation cost, few processing defects, and excellent comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

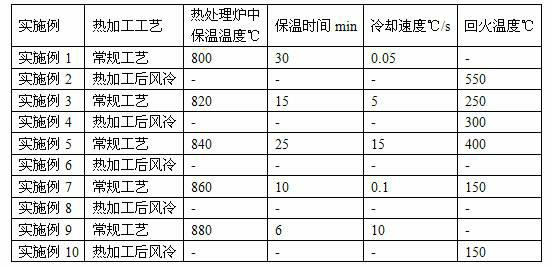

[0017] Table 2 Preparation process of plastic mold steel

[0018]

[0019] Table 3 Martensite volume percentage and properties of plastic mold steel

[0020]

Embodiment 1

[0022] The mass fraction of each element in the target product is shown in Example 1 in Table 1. The steel of the present invention was prepared according to the process shown in Example 1 of Table 2. The martensite volume percentage and properties of the plastic mold steel are shown in Example 1 of Table 3.

Embodiment 2

[0024] The mass fraction of each element in the target product is shown in Example 2 in Table 1. The steel of the present invention was prepared according to the process shown in Example 2 of Table 2. The martensite volume percentage and properties of the plastic mold steel are shown in Example 2 of Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com