Preparation method of high-quality large diameter extremely thin-walled seamless titanium tube

A seamless titanium tube, large diameter technology, applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of long process flow, many deformation passes between fires, and narrow vacuum heat treatment window, etc., to improve the size Accuracy and surface quality, increase the ratio of wall thickness to outer diameter, and improve the effect of uneven wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the present embodiment comprises the following steps:

[0024]In this embodiment, a TA1 titanium tube with an outer diameter of 101.8 mm ± 0.05 mm, a wall thickness of 1 mm ± 0.02 mm, and a length of 250 mm is selected as the spinning tube blank, and a vertical ball spinning machine is used to carry out 7 steps on the spinning tube blank. Spinning to obtain a seamless TA1 titanium tube; the chemical composition of the TA1 titanium tube meets the requirements of GB / T3520.1-2007 "Titanium and Titanium Alloy Grades and Chemical Composition"; the specific process of the 7-pass spinning as follows:

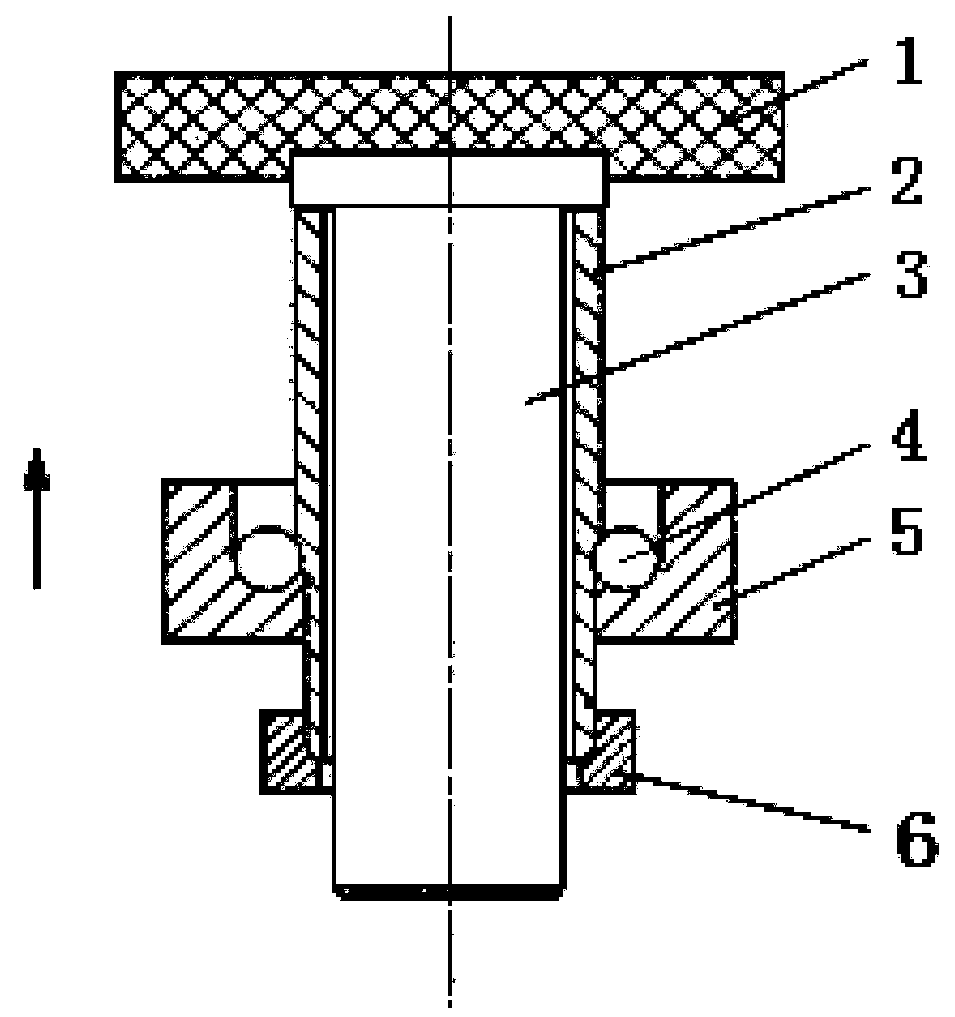

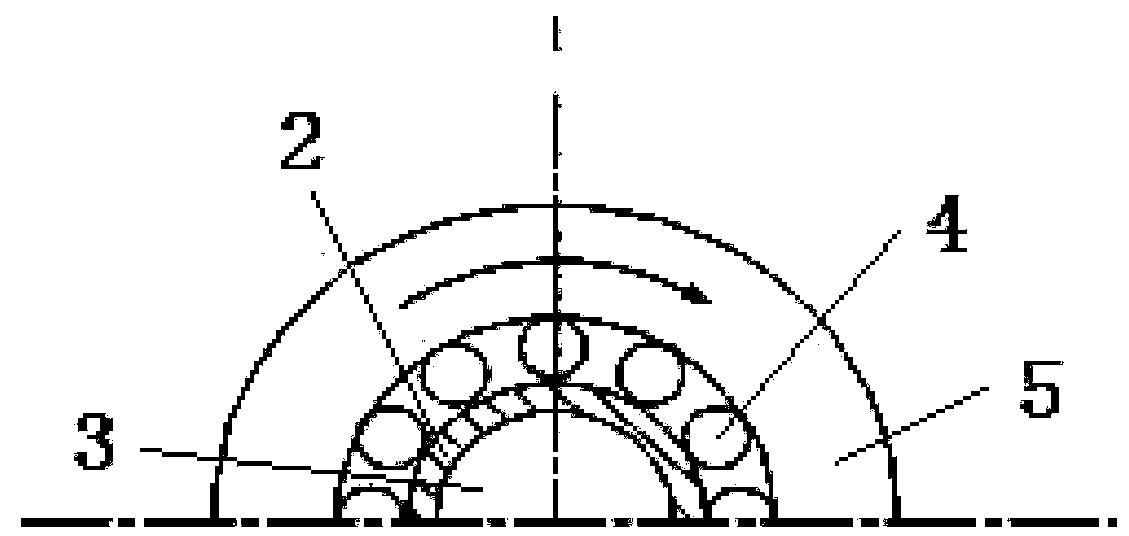

[0025] During the first spinning process, the mandrel 3 is first fixed on the chuck 1, and then the spinning tube blank 2 is set on the mandrel 3, and then the die 5 equipped with the ball 4 is set on the mandrel. On the rod 3, hang the weight 6 on the free end of the spinning tube blank 2 for spinning to obtain the first pass spinning TA1 titanium tub...

Embodiment 2

[0034] The preparation method of the present embodiment comprises the following steps:

[0035] In this embodiment, a TA2 titanium tube with an outer diameter of 161.1 mm ± 0.04 mm, a wall thickness of 1.2 mm ± 0.02 mm, and a length of 200 mm is selected as the spinning tube blank, and a vertical ball spinning machine is used to carry out 6 spinning tube blanks. Spinning passes to obtain seamless TA2 titanium tubes; the chemical composition of the TA2 titanium tubes meets the requirements of GB / T3520.1-2007 "Titanium and Titanium Alloy Grades and Chemical Compositions"; the specific 6-pass spinning The process is as follows:

[0036] During the first spinning process, the mandrel 3 is first fixed on the chuck 1, and then the spinning tube blank 2 is set on the mandrel 3, and then the die 5 equipped with the ball 4 is set on the mandrel. On the rod 3, hang the weight 6 on the free end of the spinning tube blank 2 for spinning to obtain the first pass spinning TA1 titanium tube...

Embodiment 3

[0044] The preparation method of the present embodiment comprises the following steps:

[0045] In this embodiment, a TA16 titanium tube with an outer diameter of 203.5 mm ± 0.05 mm, a wall thickness of 1.9 mm ± 0.02 mm, and a length of 200 mm is selected as the spinning tube blank, and a vertical ball spinning machine is used to carry out 7 spinning tube blanks. Spinning passes to obtain seamless TA16 titanium tubes; the chemical composition of the TA16 titanium tubes meets the requirements of GB / T3520.1-2007 "Titanium and Titanium Alloy Grades and Chemical Compositions"; the specific details of the 7-pass spinning The process is as follows:

[0046] During the first spinning process, the mandrel 3 is fixed on the chuck 1, and then the spinning tube blank 2 is set on the mandrel 3, and then the die 5 equipped with the ball 4 is set on the mandrel. 3, hang the weight 6 on the free end of the spinning tube blank 2 for spinning to obtain the first pass spinning TA16 titanium tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com