Corrugated pipe forming device

A technology of forming device and bellows, applied in the field of bellows forming device, can solve the problems of slow speed, low press-fitting efficiency and high cost, and achieve the effects of ensuring feeding efficiency, improving stability and reducing vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

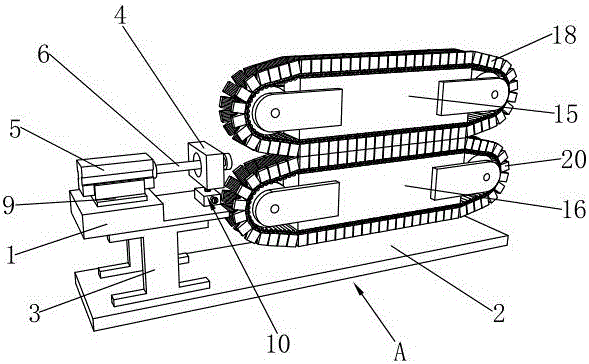

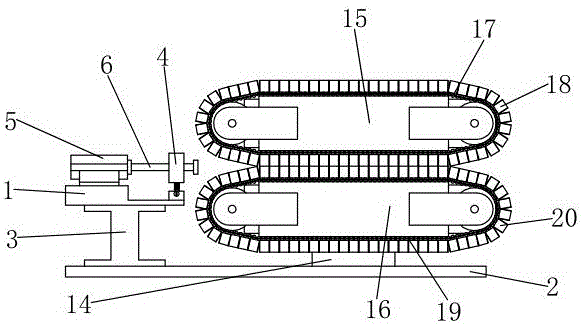

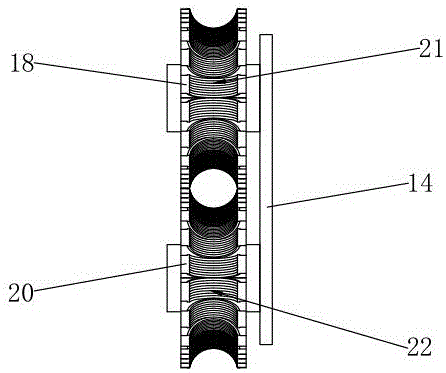

[0021] like Figure 1 to Figure 6 As shown, it is a bellows forming device of the present invention, which includes a forming workbench 1 and a supporting base plate 2, an I-shaped connecting frame 3 is provided between the forming workbench 1 and the supporting base plate 2, and the reinforcing forming workbench 1 and the supporting base plate 2 The stability of the connection between them ensures the overall stability. The forming workbench 1 is respectively provided with a driving mechanism and a positioning seat 4, the driving mechanism is located on one side of the positioning seat 4, the driving mechanism includes a hydraulic cylinder 5, a piston rod 6 and a sleeve 7, the sleeve 7 is arranged at one end of the piston rod 6, and the piston The rod 6 is set on the hydraulic cylinder 5, the positioning seat 4 is provided with a positioning ring 8, the piston rod 6 moves in the positioning ring 8, the metal pipe is sleeved on the sleeve head 7, and the hydraulic cylinder 5 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com